Hi Chopper,

You stated "Not meaning to cause dissention here. but I talked with some of our engine folks at work (I work for a helicopter manufacturer and we use radiators as cooling units for the engine and transmission

oil). Their statement agreed partially with yours, in that, all things being equal , copper/brass is superior to aluminum from a heat transfer standpoint. However, as usual in engineering, all things are not equal, and the use of aluminum allows the manufacturer to build cooling tubes which are wider than possible with copper/brass, due to the increased structural rigidity of the aluminum"

I agree with some of what you are saying, however, a couple of points.

1. Thermal conductivity of Copper = .00404 btu's per second per Sq.in.

Thermal conductivity of Aluminum = .00203 btu's per second per sq. in.

Copper is almost twice as good as aluminum.

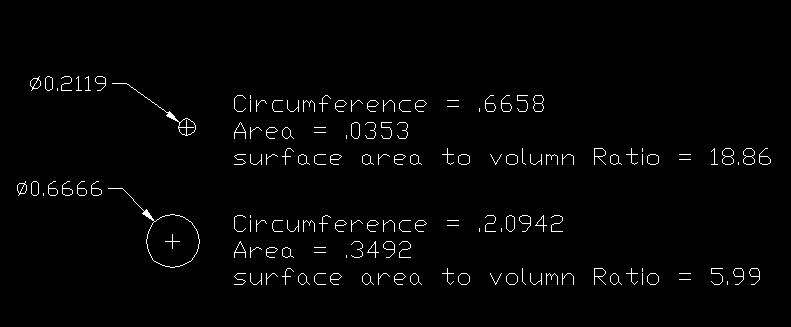

2. What is critical in a radiator is cooling surface area relative to fluid area. In other words, you wish to have the maximum amount of radiating area relative to the amount of fluid. (area of fluid as small as possible and radiating surface as large as possible). The simple explaination here is that you wish as many molecules of coolant in contact with the largest possible amount of radiating molecules.

If you will look at the illustration below you will see that a larger tube is not a good thing from an area to area ratio standpoint.

Secan is the major source of radiators in F1 cars. Their units are copper/brass. But nobody could afford to use their units in our type of cars.

Now, I personaly like aluminum radiators. They are much stronger, cheaper to fabricate and lighter than Copper/brass units. But therm to therm/btu to btu, they co not compare for pure heat transfer.