Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

1Likes 1Likes

09-04-2007, 04:46 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

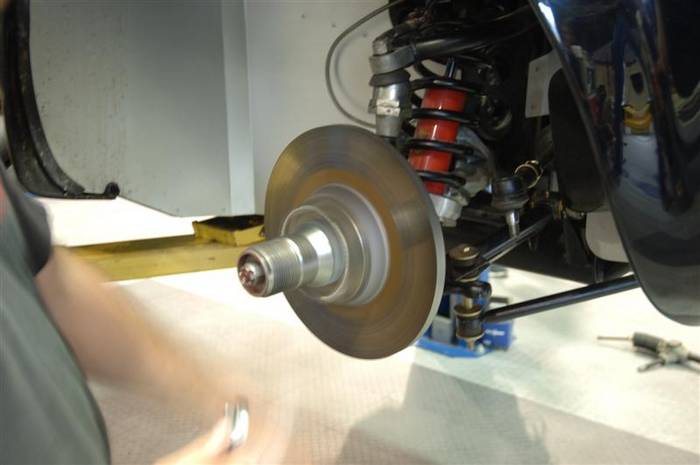

Here is a picture of the spindle going back into the front upright. Sorry for the blur! It looks like there aren't any threads on the end of the spindle, but I assure you they are there!

|

09-04-2007, 04:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a picture of the front hub assembly. The bearings have been checked and the outer bearings have been replaced to the larger bearings.

|

09-04-2007, 04:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is the outboard view of the hub and rotor assembly with the new Set 12 bearing ready to go on.

Notice the synthetic red Mobil 1 grease we use. It has a very high working temperature. If you have ever raced on those solid rotors, then you know why you need the high temperature grease.

|

09-04-2007, 04:59 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you can see the new 5/8 "D" washer we made to go with the new upsized outer bearing. The original spindle only had a 9/16 "D" washer and nut.

|

09-04-2007, 05:00 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you put the new 5/8 castle nut on.

|

09-04-2007, 05:02 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here Jeremy is giving the hub a spin while he tightens up the castle nut. You do this to seat the bearing. Just keep turning and working the bearing down tight until the hub stops turning. Then back off 1/4 turn and put in cotter pin.

Done!

|

09-04-2007, 05:13 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

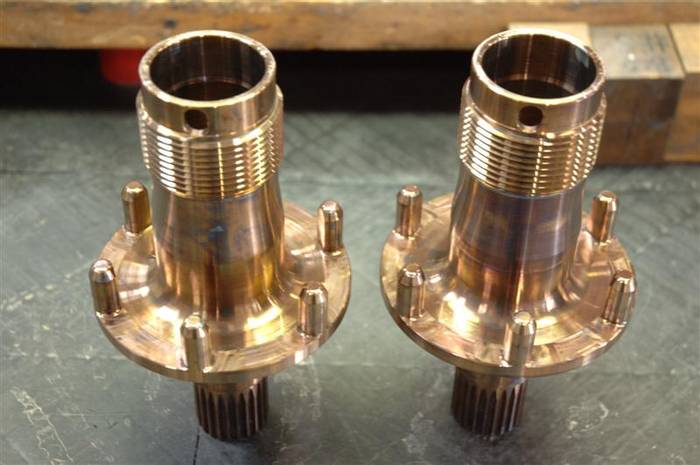

Just for comparison, here is our latest set of rear hubs. Our front hubs are very similar. Notice the drive pins are milled directly into the hub. This is done for MAXIMUM strength, MINIMUM part count, and minimum weight. By milling the drive pins directly into the hubs, we are able to make the entire part much lighter. Also, there is NEVER the question of "Did you tighten the drive pins????"

These drive pins will NEVER come loose!

The milling operation to make the drive pins is extremely difficult. At first Sandwich told me it wasn't even possible. I "persuaded" him there was enough room and he moaned and groaned, but got it done. I knew it could be done...there was at least 10 microns of tool clearance! What was all that complaining about anyway?

There is a very long reach that has to be done with the end mill to get around the snout of the hub and preventing chatter and tool destruction is a major challenge. This milling operation eats end mills like Rosie eats candy. But it makes the strongest, lightest, most corrosion resistant part possible.

Anyway, milled in drive pins is the LATEST and GREATEST mod on F1 cars which was only started this year. I like not having to keep track of so many parts, nuts, and drive pins falling all over the place and rolling under the bench.

|

09-04-2007, 06:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

I just get into this posting daze and don't realize other people are posting and asking questions. I will try to answer.

FIA-ERA,

Please PM me and I will get you out your prize!

rbray,

For heating to the temperatures I am talking about to do you any good, you will have to use a precipitation hardening alloy.

CobraV8,

Chromoly steel is notoriously bad for corrosion resistance. You are correct that a standard heat treatment on heat treatable steels actually makes the steel grow in size. But, that only works on steels that are "heat treated" by quenching to keep the martensite. For example, 4340 changes from austenite to martensite at 1525-1550 degrees F. You are correct martensite takes up more volume.

Here, however, we are working with precipitation hardening stainless steels. In our case, we "only" heat it up to 900 degrees and the process actually makes our parts SMALLER--but it is actually very, very slight. We do not quench and temper with 17-4 ph. This touches on another VERY important reason to use 17-4. It is stable during heat treat. There is no quenching to cause cracks or to warp the part. Our parts come out perfectly concentric and through hardened when we are done. You pay for it initially as it is extremely expensive--the billet alone for our hubs is $235!

You gain it back when you can sleep at night knowing your parts are the best you could have possibly made.

mickmate,

If you look in the picture, the worst corrosion is actually right by the junction of the spindle to the upright. You can see a darker band there. The bearings are sealed, but that little part of the spindle is NOT. Water gets in there and the rust monster rears his ugly butt. (But not as ugly as Jamo's)

As for the color--the straw color is the color the hubs come out of the oven when they are cooled. They darken as they cool. Notice in the above picture the blue is just starting to appear on the hubs.

mylesdw,

On an original Cobra, the hub and spindle never touch as they are separated by the bearings. It is VERY true, however, that parts that touch and rub LIKE THAT DUMB BEARING SPACER must be made out of hard steel.

Dean,

I spend a lot of nights awake trying to figure out how to do this better. One ride with a professional driver on a track and your perspective changes. WOW, these cars better be put together RIGHT! At our event last Thursday, a Miller Motorsports instructor posted lap times 30 seconds faster in one of our cars than a pretty experienced (although ametuer driver) in a HIGHLY modified Ford GT. When you ride with one of those guys (or girls) you simply can't believe what the car can do. Like I said, I only see as far as I do because I stand on the shoulders of giants.

Lowell,

I am happy to share what we have learned over the years. Hopefully it will just make the entire industry better. Over the years many, many people have shared freely what they do with us. That is where I got all the information. Like my mother always said, "There'll be more for all of us if you share."

David

Last edited by David Kirkham; 09-05-2007 at 07:33 AM..

|

09-04-2007, 07:47 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2003

Cobra Make, Engine: ERA #698 428 Toploader

Posts: 292

|

|

Not Ranked

Not Ranked

I enjoyed this thread very much, thanks for taking the time to post it. Any videos of the instructor doing some hot laps in a Kirkham?

|

| Thread Tools |

|

|

| Display Modes |

Hybrid Mode Hybrid Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:52 AM.

|

|

1Likes

1Likes

Hybrid Mode

Hybrid Mode