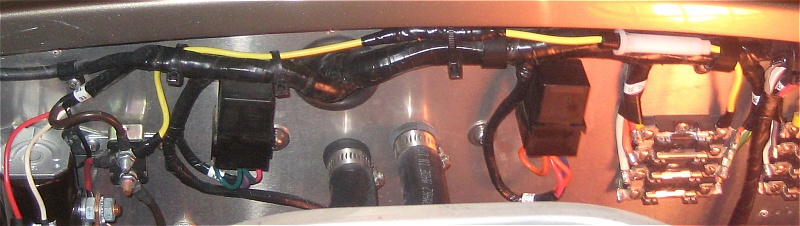

Bob P., I have the heavy duty fan, along with the pusher fans, to keep my FE cool. They all come on at the same time and the initial high amperage pull pegs the ammeter gauge to the left, the needle then sticks there, and I have to rap the gauge with my knuckle to make it come back. It's done this since the day the car was built. A couple of years ago I modified the wiring on the fans. I removed fuse #1 and ran a yellow 12 gauge wire directly from the circuit breaker to the driver's side of that fuse housing, thus bypassing the ammeter for the fan circuit (I leave the original fuse for the fan circuit out). I installed a plastic in-line 30 amp fuse on the yellow wire. Here's a picture:

That seemed to work very well. Since the fans were no longer being fed through the ammeter, the pegging of the needle problem was gone. Plus, it gave me the added benefit of telling me exactly when the fans were running because the ammeter would show a moderate charge condition if the fans ere running. I really liked this, because you generally can't hear the fans over the FE. The ammeter needle was either straight up and down, or kicked moderately to the plus when the fans were on; very convenient and very handy. Much better than a little light that some have wired in to the fan circuit because it shows the actual load of the fans running, as opposed to the little light that only shows the fan circuit is energized (a break at the last leg of the circuit, right before the fans, would still have the little light comeone, but the fans would not be running, and yes I've had a break there -- a break at the very end of the circuit wouldn't fool the ammeter, though, because there is no corresponding load).

This worked well for the last couple to three years... until yesterday. I was out in the Cobra and came upon a bit of slow moving traffic. After sitting in line for a couple of minutes I glanced down at my ammeter gauge expecting to see my "moderate charge." Instead, the needle was straight up and down, telling me, of course, that my fans were not running. My temperature was just under 90 degrees. I threw the manual fan override switch on and the ammeter needle did not move a bit -- I was now over 90 degrees; I knew I didn't have much time. I was able to make a turn down a side road, get some air flow through the radiator, then shut her down and open the hood before she overheated. Here's a picture of my inline fuse, which was the culprit:

Now mind you the FUSE DID NOT BLOW in that plastic fuse holder -- it was still as good as new. Rather, there must have been a little bit of oxidation that formed on the spring connector, which caused a poor connection where it touched the fuse. This caused the heat to melt the plastic thus breaking the circuit. The heavy amperage draw of the fans coming on/off, on/off, on/off no doubt helped contribute to the fuse assembly's failure. I made a quick repair by the side of the road and headed back home. I like my setup, but obviously I'm not going to use another plastic spring fed fuse holder. I was thinking instead of using a nine inch 18 gauge fusible link, butt-spliced in where I had had the plastic fuse.

What do you think of the idea of the 18 gauge fusible link, and I might as well get a sanity check on my whole wiring setup, too. So please tell me what you think, I'll even listen to ERAChas as well.