Warning: Boring Tech Post

Hi All,

Haven't posting much lately as I've had not much Cobra time lately. Family and work has been pretty busy. However one thing that may interest you is a T56 gearbox rebuild I've been doing for a bloke in NSW.

Apart from wanting it beefing it up and fixing the shift he bought an LS7 clutch kit from the US and it looks like there might be some compatibility issues with some gearboxes and this clutch kit. I've recommended the LS7 clutch kit myself as it seems to be a very good piece of OEM equipment at a good price. However it looks like you probably need to check a few measurements before buying one.

John bolted up his LS7 flywheel and clutch and measured the distance between the back of the block (Where the bell housing bolts to) and the tips of the fingers on the pressure plate. He got 108mm with a straight edge across it. I measured the distance from face of his bell housing to the face of the thrust bearing and got 90mm. This means that just bolting the thing together has already compressed the clutch diaphragm 18mm before you've even pressed the pedal. Probably not a good recipe for a healthy clutch operation. I believe there is some adjustment in the diaphram to compensate for clutch wear but not enough to deal with that 18mm.

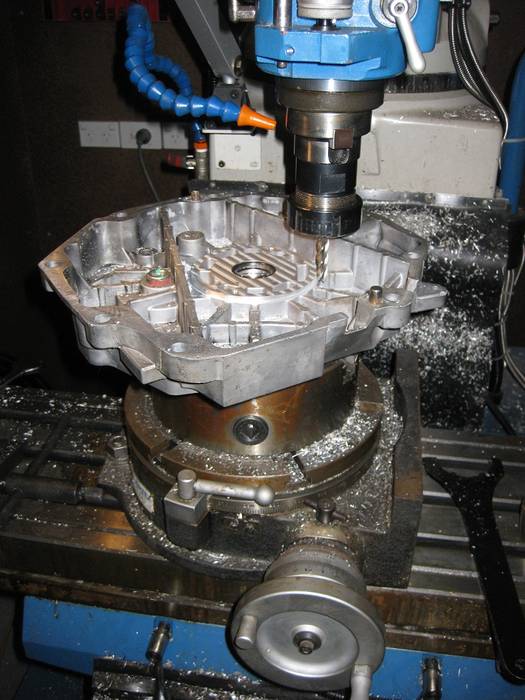

I was looking at machining up a new housing for hydraulic throwout or a new thrust bearing carriage but there just didn't seem to be any easy way to do it. In the end since I had the gearbox apart for the rebuild I figured re-machine the boss where the slave bolts to would be the neatest option.

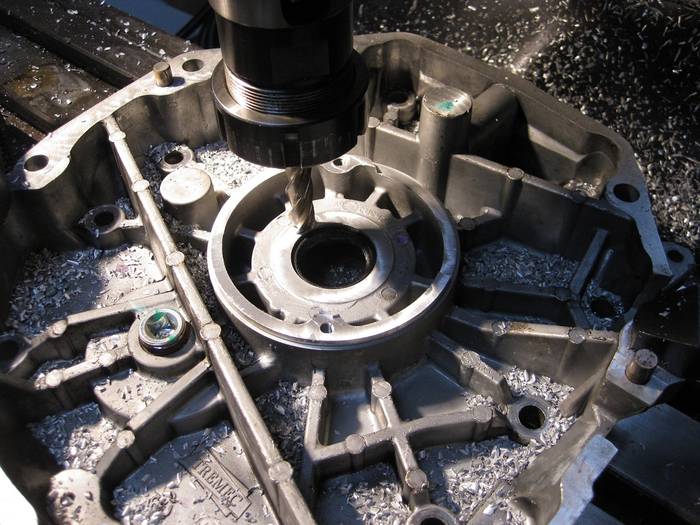

Here's the front plate of the box on the mill and I've started rough cutting to remove material from the hydraulic throw out mounting boss.

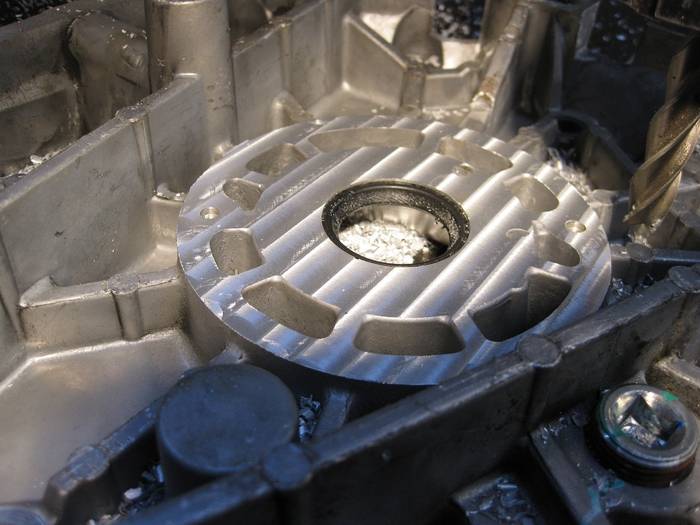

I've removed about 16mm of material and machined the boss square and flat. I can't really go any further down as I need to leave enough metal for the input shaft seal to seat against.

I've all but machined off the original bolt holes that hold the hydraulic throw out in place so have to drill and tap new ones. There's still plenty of material in the front plate to accommodate these.

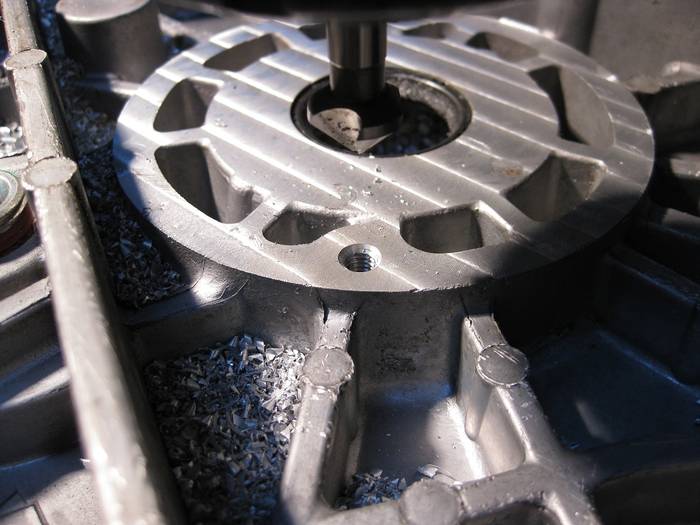

There was a register ring machined into the outside of the boss that located the hydraulic throwout central to the input shaft. This had to be machined into the new location and required a bit of thought. I looked at mounting it on a face plate in the lathe but just didn't have enough clearance to turn it. In the end I used the rotary table on the mill and located it off the front bearing race. This will keep the register ring perfectly centered in relation to the input shaft.

The new register ring. I love machining aluminum.

The end result turned out pretty good and fits like a glove.

Give it all a good clean and it's time to reassemble.

We now have 106mm from the thrust bearing to the bell housing face. I think this should be OK once we mess with the clutch wear adjusters.

I will keep you posted how it runs once it goes back into the car.

Cheers