Today I built some mounting brackets for the gas pedal. These are bolted to the side of the pedal box.

The proccess I used to build them was. First I cut a blank to the width It needs to be but I left it longer than needed. Next I took a piece of scrap of the same thickness and scribed lines where the bends should be and bent in the order that the real bracket will be bent. I then measured the piece, in this case the lines were scribed at 2 inches, the actual measurement of the part was 1.900. Now I know I need to add .100 to my measurement. Now I scribe my lines at 2.100 on my part and bend, using this method you can usually have a part that measures within a few thousands of what you want it to be. By the way, I am bending this in a Di Acro 24in box and pan brake rated at 16 gauge. Bending 11gauge is called abusing it.

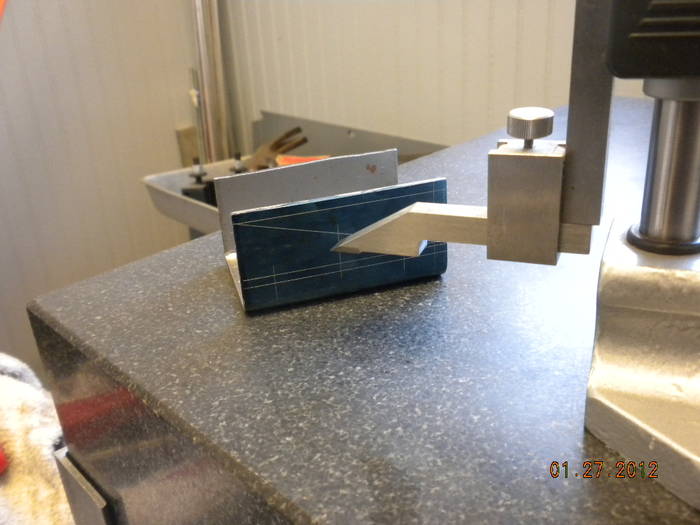

Next, I put layout bluing on the part and used a digital height gauge and layed out where the holes are to be drilled and the part needs to be trimmed.

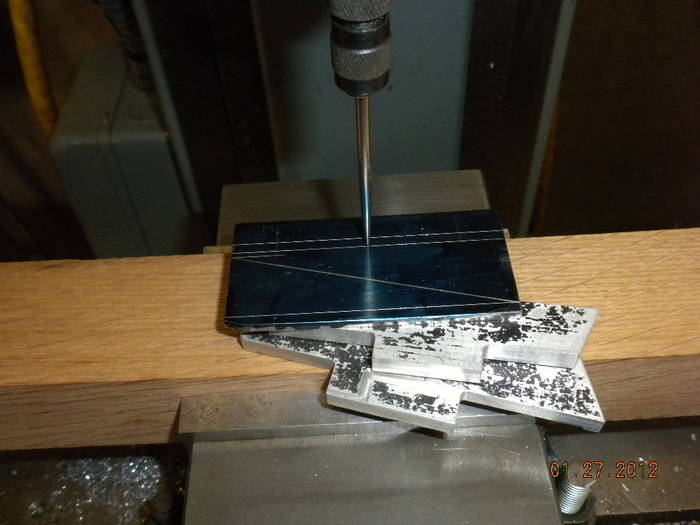

Next I clamped it in the mill and use a wiggle indicator to dial in where the holes need to be drilled.

Part is center drilled and then drilled to size and then repeated for the other holes.

For the rest of the process I didn't take any pictures. The part was cut on all cut lines with a delta 4x6 band saw. A little file work to clean up sharp edges and you end up with a nice part. Using the same process make and bend the throttle stop bracket and weld it to the other part, throw in the bead blaster and clean it up. It is then ready for paint. I will post some more when I get a chance. Mark