You just need to change the pivot ratio in the shifter itself to give you more movement at the lever. I do this a bit with my mid shift conversions.

The first question to ask is are you using the stock shifter location or a mid shift setup? This will help with working out getting a better ratio on your shifter. In the stock position there's probably a bit more room to move.

Stock location opens up more possibilities for changing the ratio.

The shifter ratio is going to be the distance from the center of the ball it pivots on to where the tip contacts the sides of the socket on the selector rail.

Most after market shifter I've seen these days are set up for short throws so this distance is quite long. Howver they usually leave a fair bit of clearance at the bottom of the socket. I like to drop the shifter further into the socket as I'm not that keen on the short throw shifts these days. Dropping it in gives you a little more side to side but the same forwards and back.

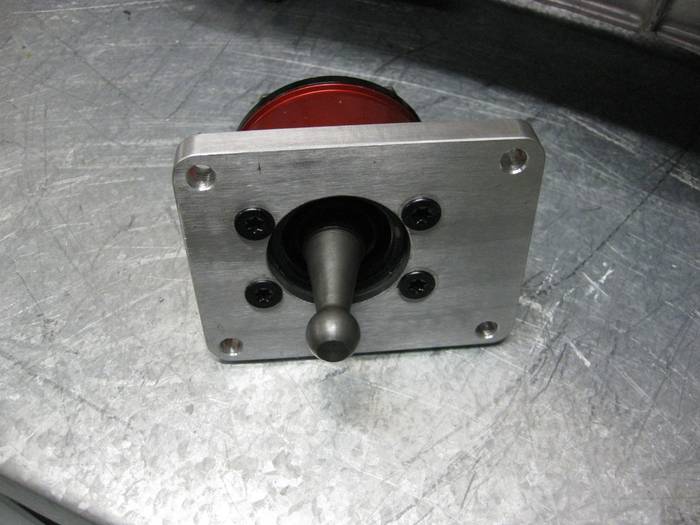

Here's a mid shift shifter I've re machined to drop it further in. This only gains you a little bit though and probably not what you are looking for.

What you really want to look at is shortening up that distance between the pivot and the ball on the end of the shifter and then dropping it in to retain the right position in the socket. You may be able to adapt another shifter with a better ratio or if you are handy on the lathe you could machine up a new shaft with the ball in the right spot to give you your ideal ratio.

Some of the B&M Shifters use a hard nylon pivot ball that slips over the rod and is held in place with a dowel pin. you could weld up and redrill the dowel hole a bit further down and change the ratio.

The other option that only works with the stock position is to remove the socket from the shifter rail. Cut it off and re weld it on further down and then machine the shifter base to drop it down accordingly. This would change your ratio and probably the easiest way I can think of.

Just some ideas.

Cheers