Well it took a lot longer than I had hoped to get it done, but at least business is good enough to not have time for G jobs! I am sorry to everybody for the long lead time. so here goes.

August 13, 2012

Metals Technology Inc.

Failure analysis, Eagle 4.250 cast (iron) crankshaft,

Description: 1 piece, as described, connecting rod, journal area

Information:

Material: A sample was cut and prepared to perform a spectrum chemistry analysis which was identified as Grey Cast Iron similar to 753. See chemistry test result sheet.

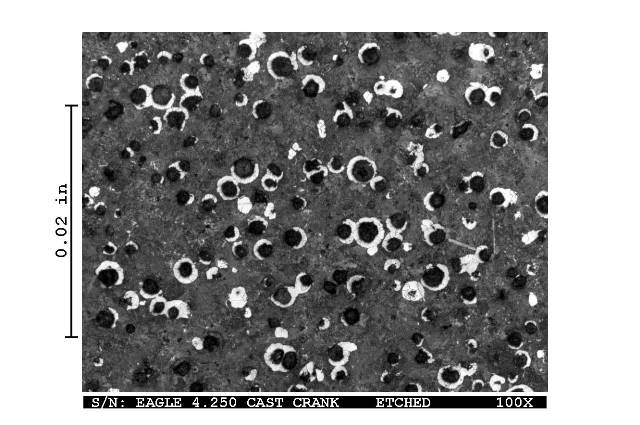

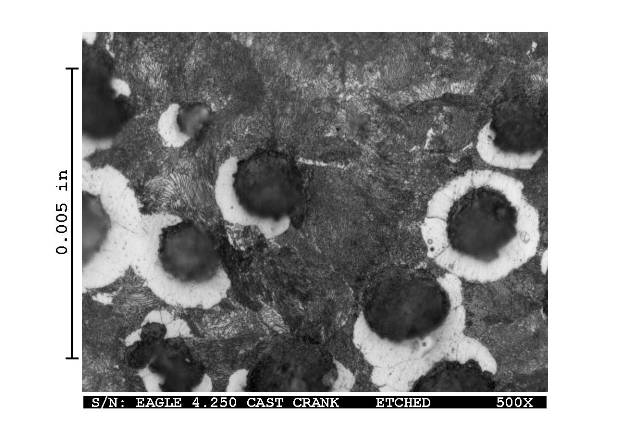

Microstructure: Type I…..Graphite Nodular…..Size 6…..Free-Ferrite envelopes in a matrix of fine pearlite, normal for alloy. See photos as polished and etched 100x, 500x.

Hardness: HRA…..Readings, 58.2 / 58.6 / 58.8……… mean = HRA 58.53

Tensile Strength: 101 Ksi

Inspection & Interpretation: Visual inspection of fracture surfaces denotes two types of fractures, MTI to identify as Side A and Side B.

Side B: Fracture shows evidence of Tension - Tension in a high normal mild stress concentration which appears to be a ductile region of final, fast fracture overload. See photo side B fast fracture. Note: This fracture (appears) is secondary to the primary cause.

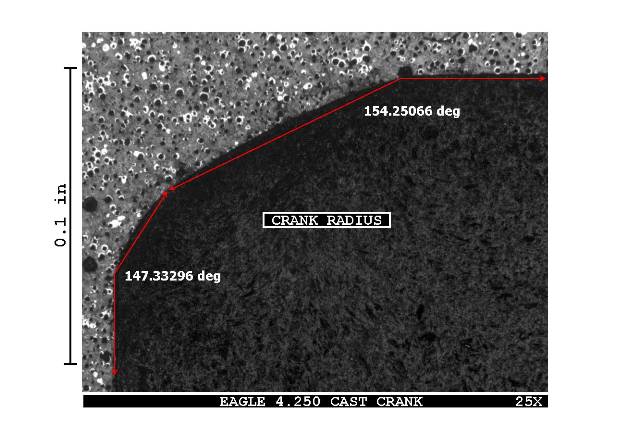

Side A: Fracture contains evidence of Tension in a high to severe stress concentration which shows a fatigue fracture with ratchet marks. A cross-sectional review of the radius profile depicts two different angles of degree, one at 147.33 deg. and 154.25 deg. The convergence of these two angles near the mid-point of the radius shows visual and microscopic evidence of crack initiation and propagation with multiple origination points observed.

Initiation direction: Long/axial,

Propagation/Convergence: Radial

Failure cause:

At high overstress or in the presence of a severe stress concentration, multiple origins will be observed in most instances with the cracks from these origins eventually uniting to form a single crack front. Before that union, the individual micro-cracks will be separated by small vertical ledges, which have been termed ratchet marks. These marks are characteristic of fatigue cracks emanating from several sites and later join to from one primary crack.

It is M.T.I.'s conclusion that the cause of the failure was fatigue caused by a severe stress concentration (stress riser) near the center of the fillet radius. This stress concentration is the result of the angular convergence in the fillet radius area due to the finial machining of the part’s radius configuration. See photos, side A fatigue fracture, origin fatigue and crank radius.

Smc