Quote:

Originally Posted by GT350Mike

problem (I don't think he used the word kerchunky but trust me…..its the same) and he was able to fix it by removing roughly 1/32" to 1/16" off the tip of the cable. I'll let you know how it turns out but in the meantime, let me know if you have any other ideas.

|

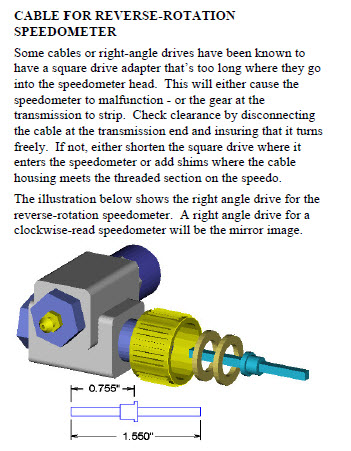

Yes, the cable trim technique is outlined in the ERA Manual. Here I ripped that for you (don't tell Bob P.). The nice thing about a speedometer problem is that there are only a limited number of problem parts, they're all inexpensive (except for the speedometer itself), and you can easily recreate the operating conditions from the comfort of your own garage. The problem has to be either 1) the plastic driven gear on the end of the cable at the transmission; 2) the cable itself, the length of the inner cable, or a tight kink in the cable; 3) the right angle reverser. You could replace all three for less than a hundred bucks. A new speedometer cable is only ten bucks, which is less than the

Dri-Slide, but that's how we are....

The almost sure-fire way of diagnosing your problem is to remove the cable from your transmission and inspect the driven gear for any wear. Let's assume it looks perfect. Now remove the cable from the reverser and remove the reverser from the speedometer. With the reverser off the cable, you should be able to spin the cable with your fingers from the driven gear end and it should feel nice, easy and smooth. If it is not, then pull the inner cable out from the outer cable, inspect it, and lube it with Dri-Slide. Next step is to put your driven gear in a reversible drill, spin it at full speed and use the little lock button on your drill to hold it there. Put your hand on the outside of the cable, close to the speedometer end, and feel for vibrations. It should be nice and even. Remember how that feels. Now try turning the reverser, with your fingers, from the little spike that normally goes in to the speedometer. It should be harder to turn, but doable with your fingers, and it should be nice and smooth with no rises, nor falls ,in perceived vibratory tension. Now put the reverser on the end of the cable and fire up your drill again and feel for vibrations. You should not be able to feel a "pulse," but instead it should be nice and smooth. If you feel a pulse, or unusual vibrations, first loosen the cable threads to mimic "shortening the inner cable" and see if that helps. If so, then the inner cable could be bottoming out. If the vibration is still the same, then grease the reverser gently. Turn the gears a bit by hand, grease again. Repeat the test. If you still have vibrations, then grease it

hard with your grease gun. You will not be able to turn the little spike with your fingers after a high pressure greasing. Use a nail tip to push the pin in on the Zerk fitting and some grease should pop out from the excess pressure. Now gently turn the spike with pliers. It should loosen up so that you can turn the spike with your fingers. Now retest with the drill. If you still have vibrations/pulses then you should replace the reverser. If it seems good, then put the reverser back on the speedometer and fire up the drill. See if the needle holds steady and the vibrations on the cable are smooth and consistent.