Top thread, as always, Mike.

Anyway, the solution to my alternator issues was far less elegant than yours I'm afraid.

I did manage to get the clutch pulley of with a 17mm Inhex on the rattle gun. It turns out is is a reasonable standard shaft and threaded end, thankfully.

I popped into my local auto elec, introduced myself, told I'm I was building a kit and he cut me off and said he doesn't have the man power to rewire looms for kit cars! Hah! Must have had a bad experience! Or knows how long it takes - that's my next job so I was a bit worried...

Anyway, he was in fact very helpful and dug around and found to candidates pulleys for my alternator, both a little worn, that I could try. No charge! Top bloke!

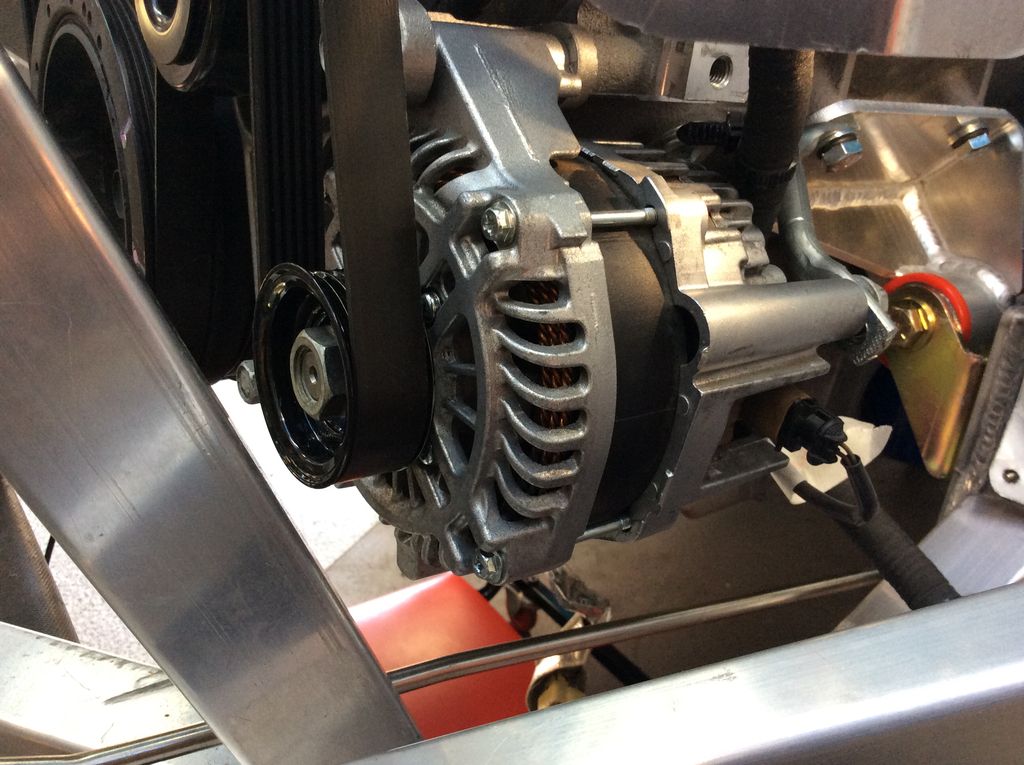

I made the one that was slightly larger fit, with a few spacer washers. It is only about 4% oversized but after the warnings about over revving and burnout on gm alternators, this can't hurt.

I cleaned it up, gave it a dip in the black engine enamel paint tin, and Bob's your uncle!

Im a little concerned about the one turn of thread still exposed on the retaining nut, however it is a reasonably large flange nut and I've used a good dose of locktight. I'm think I might either twist wire it or dollop some glue on the top just in case. That pulley obviously turns clockwise so it help to keep it tight.

And as you can see the clearance is actually excellent.