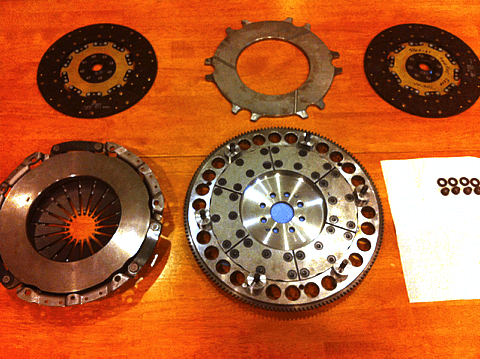

I chose to go the dual disc path but decided to build the clutch myself. I got a deal ($80) on a FRPP billet steel flywheel. It started out SFI approved before I cut it for heat shield biscuits and swiss cheesed the perimeter.

I used a 10.4" FRPP M7563-C302N pressure plate with the high ratio diaphragm spring for a reduced pedal pressure. The Floater came from Crower and was one of their 10.5" blown alcohol pieces with a 0.350" thickness if I remember correctly. The stand bolts are ARP 2000 rod bolts and the actual stands are 1.25" steel bar I machined to look like stands. The replaceable heat shield biscuits I bought from Crower. They come from a 10.5" slider assembly for a blown alcohol clutch — again. The real benefit is the ability to replace them as a consumable instead of surfacing the flywheel or buying a new one.

Here is a pic of the pieces all laid out.

The discs were a little challenging at first. Then I remembered a clutch shop that made clutches for farm tractors. I stopped by and explained what I was attempting to do. He said no problem, I make clutches for tractors that haven't been made for 50 years. This is a walk in the park. The rest as the saying goes was history.

I used an organic facing because I was after street manners. The hubs are unsprung and the friction material uses a marcel spring between itself and the drive plate. A marcel spring is a wavy spring sort of like a bellevue washer but wavier (if there is such a word). The idea is as the clutch engages the marcel spring provides a soft engagement because the friction material literally compresses the marcel spring preventing the grabby experience solid hub discs usually provide.

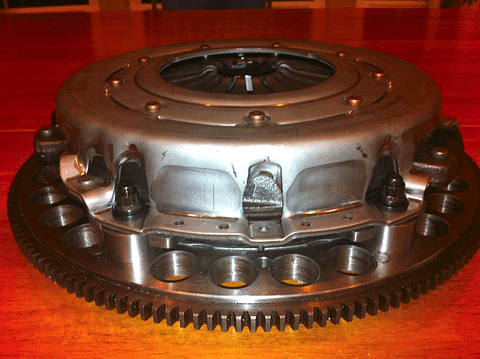

The entire clutch assembly looks like this,

Stuff like stand height is relatively easy to noodle out. It is simply the additional height added by the floater and additional disc plus clutch pack clearance in the released condition.

All in, the cost including the drills, reamers and carbide cutting tools was around $625 if I remember correctly. Depending on what you can source parts for and how much effort you want to spend in searching out deals your mileage may vary.

Almost forgot the clutch cover is the same one Ford calls the King Cobra and Brent nailed as a Valeo unit back in post 12.

If you are motivated and want to have some fun making stuff, this kind of a project will put a smile on your face.

Ed