Quote:

Originally Posted by eschaider

Ace,

There are two commonly used techniques for setting up ring and pinion gears. One is the appearance of the drive and coasting tooth contact patterns and the other is the Master Housing Depth or MHD method. Advocates of a particular approach have an almost a religious loyalty to their preferred method.

Each approach has its advocates and detractors. The tooth contact pattern approach usually will find as many opinions about shallow, deep, loose, tight as you have people to look at it. The problem comes from the subjective quality that visual appraisals of the tooth contact pattern before your eyes (or theirs) are subject to.

The MHD approach uses a Master Housing Depth dimension from the differential carrier bearing center to specific location on the pinion gear to set pinion depth. This dimension is the same for all rear ends in a given family i.e. Ford 8.8 inch, Ford 9 inch etc. Once you have pinion depth set you can easily zero in on your backlash dimension using shims on either side of the carrier to get you where you need to be.

The MHD approach requires no subjective visual evaluations everything is measures in thousandths of an inch. The drawback to the MHD approach is you need to be able to read a micrometer and you will end up making a few pieces of simple tooling to do the job. BTW, MHD is the way Ford sets up the rear ends before they leave the factory.

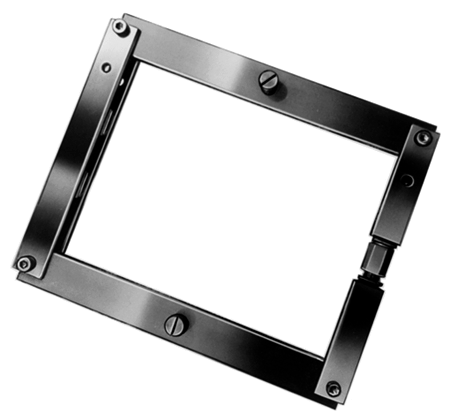

In the tooling department you will need a case spreader. and a 1" thick plate for measuring pinion depth (I provided a drawing below) along with a dial indicator and stand for measuring backlash. I have attached pics of case spreader and a drawing of the plate for you to duplicate. The case spreader can be bought from Rotunda for lots of money or fabricated from plate, bar stock, dowel pins and a turn buckle form McMaster-Carr for lots less money.

Case Spreader

Pinion Depth Plate

Pinion Depth Plate

The third item I wanted to attach is an excellent write up on setting up rear ends using the MHD approach for Chrysler, GM and Ford rear ends by Randy's Ring & Pinion but the pdf file exceeds the site file size limits so instead I will provide you the url to down load it from.

Click here => Ring & Pinion MHD setup for the booklet. This used to be a nicely printed pdf but the visual quality appears to have deteriorated a bit in recent years. The important thing is the information is still correct and the pdf is downloadable.

Just in case you are one of the folks that embrace the reading of the tooth contact pattern method for setting up rear ends but don't know what to look for in terms of tooth contact patterns, here is the link to Dana's tooth pattern guide, click here => Dana Tooth Contact Pattern Guide

By far and without any doubt whatsoever, the absolute quietest, longest lasting rear ends I have had over the last 40 years were the ones I set up myself using the MHD method.

Ed |

Ed, thanks for all the information. I will take some time later tonight and review this. Sure didn't realize there was more than one way to setup a rear gear set.

Quote:

Originally Posted by 1795

I would check with your engine builder regarding how well your big block will like 2,000 rpms. Depending on the cam, it may not like it at all. With a mild cam that may be k, but an aggressive cam is going to want a higher rpm to run right.

|

If the big block is the direction that is decided this would be something that is discussed. Based on how many cubes you are running you may be able run a milder cam with such large displacement and still have more than enough power.

Quote:

Originally Posted by fastd

I actually prefer the .82 5th gear; and your 3:31 rear gear sounds like it would be a good match. The KC 427w should actually be a delightful set up. Maybe you should think about changing the cam.

What kind of horsepower and torque are you putting out? It would be helpful to have it dynoed so we can see you power curves.

What kind of power are you shooting for? I would think you can easily get 450-500 hp out of your current setup. I personally would not like to go to 3.73 from a 3.31 and 2700 rpm at 70 is closer to ideal than 2000 rpm. If you are driving long highway distances I can see you wanting to bring it down to 2200-2300 but not lower.

If you want to go to big block than go for it but you have a great setup currently imo.

|

I enjoy everything about the 3:31 except for when I'm out on the interstate and I'm turning 2800rpm in 5th.

The dyno sheet from when Keith built the motor was peak HP 590 north of 6600rpm and TQ was in the 570's. I had the car tuned by Wayne Presley and a new QF750 mechanical secondary carb put on the car. To my own fault I had really gone through the car and it needed some care. The rev limiter was sat at 6000rpm, the fuel pump was some tiny little unit and the fuel lines were ridiculously small. After the car made less than stellar numbers I talked to Brent and we upgraded the fuel lines, fuel pump and changed the MSD chip to 7000rpm as well as changed the springs in the distributor......this really woke it up but still not enough for me.

The car on a mustang dyno was making peak TQ the wheels of 350 at 4500rpm and the HP was 360 at 6000rpm. These power figures were before I got it home and we made the above adjustments. I have a local dynojet that I can go through it on and I should probably do that to see where it is at now. Something also to consider is the car has 2" headers......so you have a huge set of headers, no rear gear and a higher rpm cam.

Brent said in his opinion the current cam was not ideal and had way too much split in the duration with too much overlap. I have another cam he specified just have not stuck it in yet......the gearing change was just a cheap way to pick up some acceleration but would make the 5th gear situation worse and I would have to accept that.

Quote:

Originally Posted by Dwight

I forgot, which TKO do you have?

The 600 has a 2.87 first gear. That is why I picked it over the 500. Much better 1st gear for street use.

Most of the guys are running 3.25 to 3.55 rear ends. The few with 302s and 351s that run 3.73 turn high rpms on the hiway.

Right now I'm driving a 408 KC that will cruise below 2,000. 3550 (.68) 3.55 26" tires

found this in my files

8.8 Axle Gear Install |

Dwight,

I have the .82 5th gear TKO-600