Quote:

Originally Posted by Texasdoc

So if I get 70 PSI at 3000 RPM cruise with 0W-40, I should decrease the viscosity to 0W-30 or 0W-20 to get the pressure down. Lower pressure = higher flow. It is the "flow" that provides protection, not the pressure.

Thoughts on this logic?

|

If lower pressure provided more flow then you could reduce your pressure to zero psi and get maximum flow. I have noticed that whenever my

oil pressure is at zero the flow is also at zero. I suspect your experiences might be similar.

Dr. Dmitri Kopeliovich is the Director of Research at King Bearings and has been with them in that capacity since 2000. He has published 500 or so papers on Materials Engineering and Materials Engineering related subjects. He is responsible for a significant portion of the original research in the design, development and production of King bearings for both racing and non racing applications.

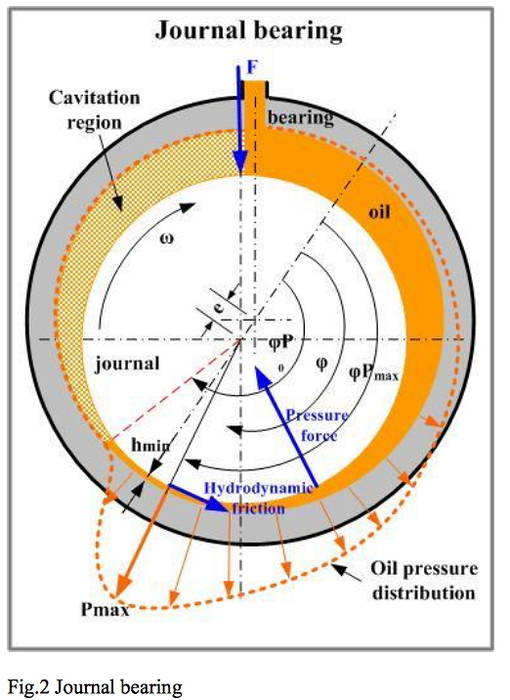

The following figure is from one of his papers

Engine Bearings and How They Work (<= clickable).

Figure 2 above, graphically depicts how the

oil is literally pumped into the space between the crank journal and the bearing insert by the rotating journal. Some of Dr. K's words, on the phenomena, which you can read if you choose to download the paper;

"Fig.2 demonstrates a hydrodynamic journal bearing and a journal rotating in a clockwise direction. Journal rotation causes pumping of the lubricant (

oil) flowing around the bearing in the rotation direction. If there is no force applied to the journal its position will remain concentric to the bearing position. However a loaded journal displaces from the concentric position and forms a converging gap between the bearing and journal surfaces. The pumping action of the journal forces the oil to squeeze through the wedge shaped gap generating a pressure."

There are a wealth of additional bearing, lubrication and performance related white papers the good Doctor has published that are downloadable from the King Bearing website. I think you will find a very well organized and presented technical emporium of information specific to bearings, lubrication and race / performance engine applications that is factual.

Ford went to progressively heavier oils for their higher powered engines. The low viscosity oils they recommended for their daily driver types of vehicles had to do with CAFE (Corporate Average Fuel Economy) standards the Detroit Car Makers were required to meet.

Ford likes a 5W-50 weight oil for the new GT350 engine. Most Windsors and FE's are assembled with looser clearances which would encourage me to run something more like a 15W-40 or 50 oil if it were my engine.

Here is a pic of Ford's oil change kit for the GT350. Note the oil weight on the bottle;

The little pipsqueak engine I run uses 15W-50 Mobil 1

synthetic. My engine idles at about 900 rpm with 65psi oil pressure after it warms up. When it is cold, at first start, it idles a little north of 110 psi. When I am driving in traffic at 1800 rpm it has a little over 85 psi of oil pressure.

These slightly elevated oil pressures will consume an incrementally small but real portion of your engine's power to maintain. It absolutely guarantees a more than adequate oil delivery to all bearing surfaces in the engine as long as there is oil in the pan and my oil pump is spinning. I have never wanted for that incremental horsepower.

BTW in the FWIW category the relationship between pressure and flow for fluids is a second order relationship where the pressure increase is equal to the square of the volume increase. If you wish to double the volume flow of a fluid thorugh a given orifice then you will need to increase the pressure by a factor of 4. The bearing clearances we run in our engines represents the orifice referred to above.

You should do things for your engine that you think are best for you (and your engine).

Ed

p.s. If you choose to run high volume, high pressure oil pumps you also need a properly baffled, high volume oil pan. If you do not use one, you will pump your pan dry and smoke your engine's bearings which is one of the issues Brent was cautioning you about. Take a look at Fords oil change kit for the GT350 one more time. There are ten quarts of oil ...