Olddog,

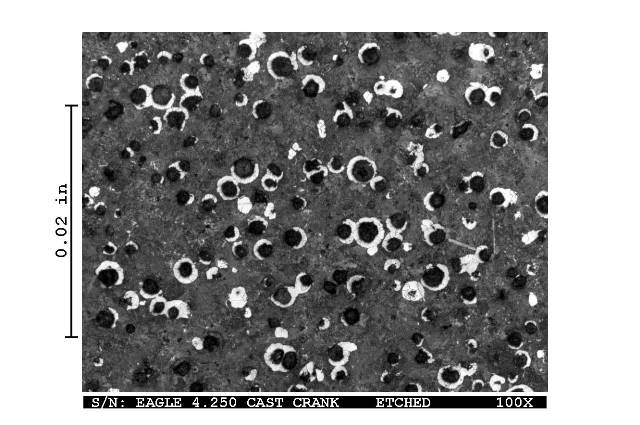

"Cast crankshafts" are typically made of cast, Ductile (Nodular) iron with a Carbon content of 3.0-4.0%. (“ Cast Steel” by comparison is typically .1-.6%) These materials are characterized by a spheroidal graphite morphology as can be seen in the photomicrograph below

.

It is the sphereoidal shaped particles that mitigates stress concentrations and allows for the higher strength and fatigue resistance, allowing its use in this application.

Brent,

Why is the margin higher on the forging? I would think the markup would be the same

There is no question that a properly prepared cast crank is capable of supporting the majority of builds. They just lack the fatigue strength and resistance to crack propagation that is found in a forging. I always think about what happened to Eljaro back in 2011

Eagle 4.250 Cast Crank Broken

That was enough for me. $500 isn’t going to break me on a $15-$20k motor. I’ll buy rotating parts at the top of my budget, not the bottom…..

Here is an excellent study that was done in 2007

http://www.autosteel.org/~/media/Fil...ve_summary.pdf