This is my 390 dyno mule:

This is a 4.060" x 3.780" combination with a few leftover parts laying around the shop. It features forged Racetec pistons with an 11:1 compression ratio, Molnar rods, and a set of 428CJ heads that have been mildly ported and stuffed with some leftover 5/16" stem and 7mm stem valves, 2.08" & 1.63".

I had planned to use a new Blue Thunder MR 2x4 intake, but the ship date kept getting pushed further and further back, so it got a new BBM Tunnel Wedge that I had on the shelf. Carbs are a pair of Holley 600's.

The clincher of this engine is that it's a hydraulic roller engine. In years past we have all dealt with rpm limits of around 6000-6200 with FE hydraulic rollers, due to lifter type, valve weight, rocker arm design, etc. Over the years, we have tried different things to open that up, since a lot of my customers just don't want to be stuck with solid roller and solid flat tappet engines. A hydraulic roller camshaft is as zero-maintenance as it gets and to have one that will pull some rpms is an added bonus.

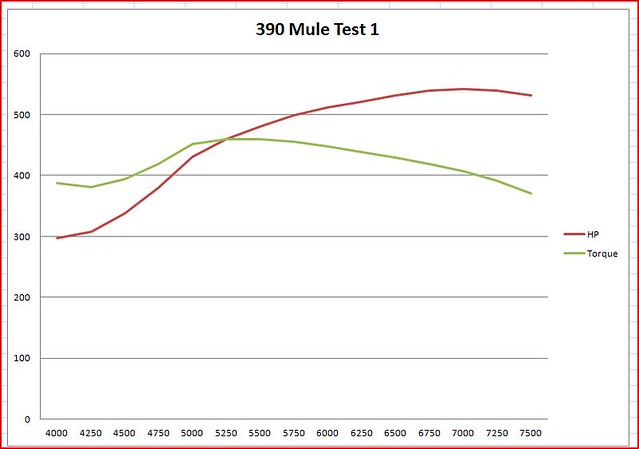

Here's the result of this one:

https://www.youtube.com/watch?v=C_JY47anClA

https://www.youtube.com/watch?v=C_JY47anClA

This engine cleanly went to 7500 rpm and probably would have went a little higher if the cylinder head had performed a little better.

This is the result of lots of dyno testing over the years, as well as the introduction of some new parts that lend themselves to high rpm operation.

Several of us have found that factory non-adjustable rocker arms would extend the rpm range of hydraulic rollers by a significant amount. However, in order to reach much higher rpms, the spring pressures go up and the need for a smaller valve stem pattern is more important. That led me to introduce this new product:

This is a roller-tipped, bronze fulcrum, non-adjustable rocker arm for the FE. These are made for me by Harland Sharp. The elimination of the adjuster off the rear of the rocker arm greatly reduces the inertia of the rocker and extends the rpm range, just as a titanium retainer, small valve spring, etc. would do. The result is a rocker arm that will take up to 700 lbs of valve spring pressure but has a roller tip that is small enough to work on something like a 5/16" stem valve.

Combining this rocker arm with a camshaft that has the right lobe shapes (not too lazy, not too aggressive) and the correct valve springs will result in extreme hydraulic roller rpm limits.

The 390 is a dyno mule and I have ordered a few more camshafts to test. However, to my knowledge, this is the only 7500 rpm hydraulic roller FE in existence and getting those results was a breath of fresh air to me.

Thought I'd share....