Hello again,

Time for another update! Still busy with other house related stuff but fall is winding down now and things are tucked in for the upcoming winter, Our wood is piled in the basement, the screens are put away, the snow tires are on my wife’s car and I will probably do mine this weekend. Oh boy! Here comes winter again.

I caught up with a friend recently, and he asked how the project was going. I pointed him to our little forum here so if you are reading along…..Hi Bernie!!

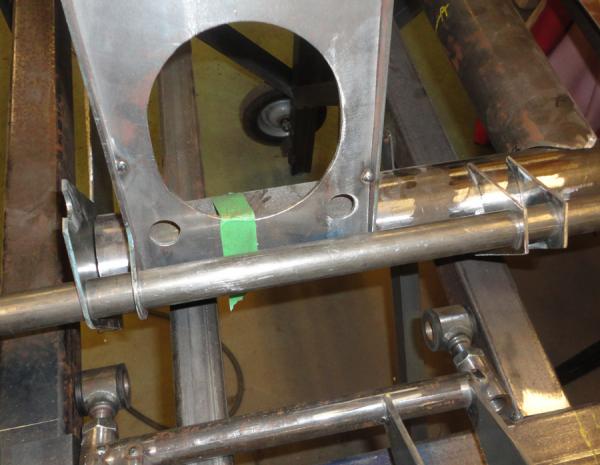

I have been making some progress on the car too, I built the rear chassis mounting end of things.

The lower was fairly straight forward as I am using the stock mounting points although I have moved the front one forward about 9/16”. The upper was kind of just a point in space and I needed to fill in the gap so to speak, while also trying to keep everything in the same space as the original transverse leaf and shock parts occupied. I think it is a winner but won’t know for sure till I am doing the panels for the interior and trunk.

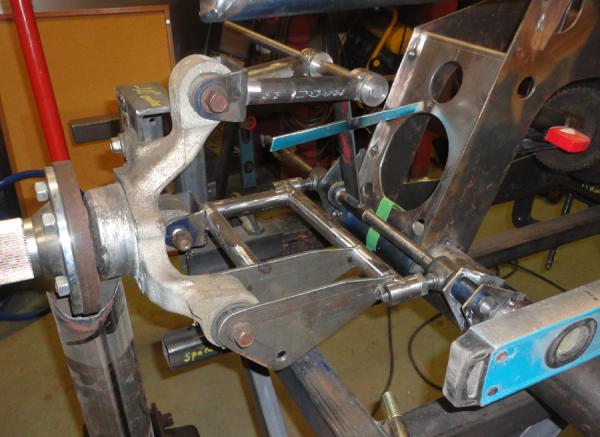

After I had the lower mounts tacked in place, I made a little spacer jig to hold the upper arm mount center in relation to the lower mount center. Then some CAD work to figure out the shape of the upper mounts and then layout, cut, bend, check fit, rework and check again, ….tack weld….

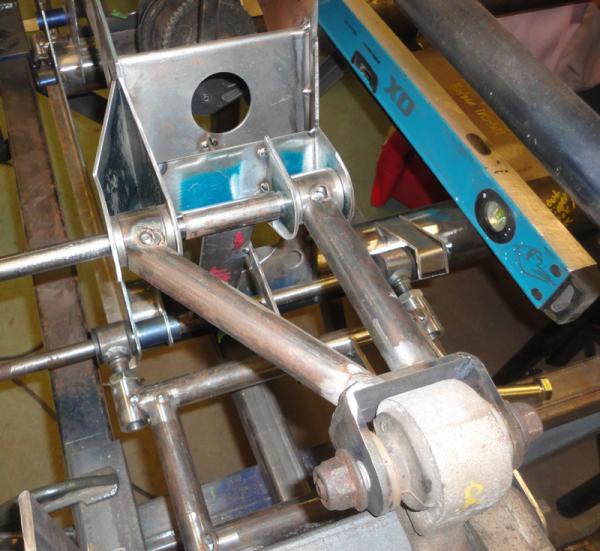

I also managed to mock up for the rear shocks with the arms and hubs in place, build some more brackets and the upright tubes and then test fit stuff.

I also ran the suspension through its travel range and checked clearances and camber change. All is looking good so far. I might need to rework one of the cross braces on the lower arm to clear the CV boot but I am also considering different axle and CV joint options.

Mostly I am thinking about the Porsche / VW 930 type joints as they are a bit more compact and frankly better looking and I already have a certain familiarity with them from my previous life. It is not an easy bolt in conversion but might be worth doing, it will depend a lot on how much length change occurs over the suspension travel. Ford has used a tri lobe joint on the inner end that would indicate a lot of length change was required but I am not using their geometry so we will need to wait and see as I did not think to measure that when I was checking other things. More on this later I am sure……

On a side note, We also made a day trip to a fellow about 3 hours away who trades in used MGB stuff. I picked up a good used front right hub as mine had a couple of the outer threads missing somewhere along the way and the more I looked at it the more I just did not like it. Also an early windshield wiper motor assembly, it will most likely need an overhaul ( don’t they all?) and I will change it to 2 speeds, but it is Lucas and the right shape. And happily, an early MGB steering column!

I had the outer tube but not the inner shaft and it did not look like much fun trying to machine one, even with Chuck’s great drawings.

It’s what AC used back in the day so good enough for me. The trip was bit strange though, I had sent the guy a list as I wanted 2 early steering joints as well and even though he said he had them and I pointed a couple out on steering racks, he basically refused to take them off claiming it would take hours “ just buy some new ones “said he, actually strangely he had nothing ready for me when I got there and we had to go looking around his outbuildings and basement for everything, a nice enough guy though and I did get some parts, you live, you learn. Perhaps he just wanted some company for awhile... I now do have 2 nice early u joints coming from England for a really great price too….thanks eBay…… In the end it was a nice day out with my beautiful wife and the dog too, well I think the dog had a good time.

Then I got to welding, not just tacking but really welding stuff.

Do you ever have a project or task that somehow you just can’t seem to commit to, sort of work all around it, just keep putting it off because…well you’re not sure why, lost your nerve, perhaps you’re just unsure how it will go or something?

I think I was putting off really welding things, I had everything well tacked but…. I just need to be sure, I might want to change something you know. I think in the end I was scared to commit to it, as I have said before it has been a long while, like 16, 17 years since I have really done any work like this.

Back then I was all practiced up, wouldn’t think twice about it, what are you waiting for? Just build it

. Perhaps that stemmed from youthful ignorance or just 10+ years of doing such things, perhaps the former lead to the latter or a combination of both.

Whatever it is I guess I am worried I am “out of practice” but I just got to a point where I had to make a real weld before I could tack in another piece of the structure. So I made some practice passes to get the settings where I liked them and then…made a couple of permanent welds!

It’s not like I haven’t been welding lately, I have been acquainting myself with the new MIG welder for a while now, I built some shop tools, made a new frame for my trailer, built the jig table, landing gear for the chicken coop, etc., BUT THIS IS A REAL CAR! MY CAR! Or something like that, not sure what it was but I am sure I was avoiding it, but then once I started……..

I just could not stop….. a weld here, another weld over there, around the other side, some up top. Just working my way around trying to keep the distortion under control, just like old times, Oh boy!

So the rear suspension tower area is all welded up at last, it is very solid, I am happy with it. They are all not the perfect fish scale beads we see in glossy magazines but I know they are structurally sound with good penetration and complete coverage. Fancy little stuff you will see in the end I will do with the TIG but for the main structure it’s too slow and expensive to operate ( Argon vs CO2 ) and I will be sand blasting the finished chassis and coating it in POR15 so it will all look the same then.

Speaking of POR15, I did “finish” the rear upper suspension arms! They are welded, blasted and painted, my first “finished” parts and I am very happy with them….

I will now turn my attention to the front of the chassis….oh boy, can’t wait!

Lower mounts

A point in space.....

CAD !!

Check those clearances....

Started going crazy with the welder...

Full droop.

Welded...

Painted !!