Cobrabill: I see you have had personal experience with a clutch/flywheel failure, but it was with a large diameter flywheel and clutch. The HEMI GTX didn't use a small clutch or flywheel. I've also had many experiences, but mine have been with hardcore racing. Yes, I've had the disc shed its flacings during a 7,500 rpm shift, but that's not what we're talking about.

You're right, no clutch disc, pressure plate or flywheel is immune to failure, but if the right components are used--I was speaking of small-diameter clutches of under six inches and light, flex-plate style pressure plate--the chance of failure is so low it becomes insignificant providing the components are installed correctly. I am not saying this without base, having designed or cooperated on the design of all types of cars, from Indy, TransAm, Pro Stock and off road, to name a few. Check out the setup Olthoff's use in their Superformance clutch and flywheels. I have seen many nasty stuff when acting as an expert in may cases involving clutch/flywheel failures. But in all my travels within racing circles and litigations, I've never seen a clutch such as the type I have mentioned fail due to centrifugal forces.

By the way, I have a Lakewood b/housing fitted to the back of my 427 s/o.

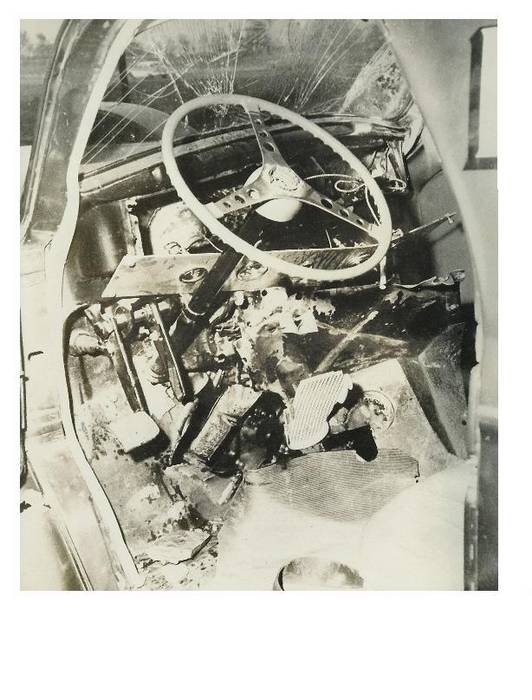

Here's a picture of a '40 Ford Gasser with a sb Chevy in that had a flywheel come apart during an 8,000 rpm shift. This was in the early days when scattershields were not required. This is why NHRA institued the requirement.