Jeff: It's always safe to error on the safe side, so I recommmend that you check piston-to-valve clearances. I go over both methods--clay or dial indicator--in detail in

Racing Engine Builder's Handbook. Either way, you should have 0.100-in. minimum axial clearance and 0.050-in. radial clearance when using steel rods. Install the head with an old head gasket to give the correct piston-to-head clearance.

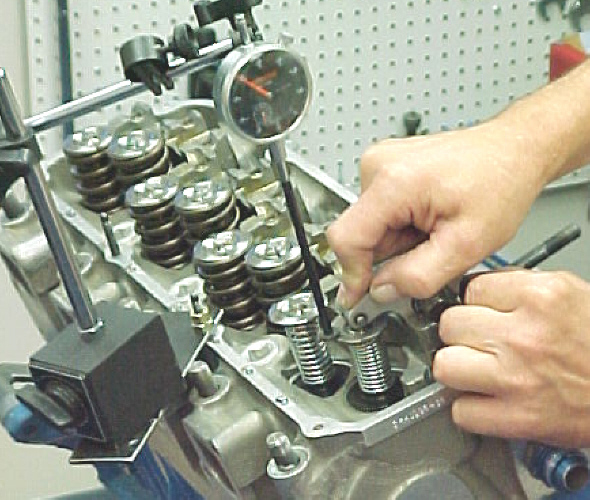

Using the age-old clay mash method works well, but I prefer using bounce springs in place of the valve springs. Set up a dial indicator square to the spring retainer to see how much clearance there actually is at different crank positions. Either way, you'll need a degree wheel at the crank. Using the indicator method, just push down on the valve end of the rocker arm to open the valve farther to check actual clearance. See photo from the book.