VC, bolt hole drilled and tapped; thanks Rick.

****-canned the stainless bolts and went with steel. I may have to worry about rust on the bolt heads but I won't be twisting one off with a T-handle. Here are a couple of pics showing how it's coming together;

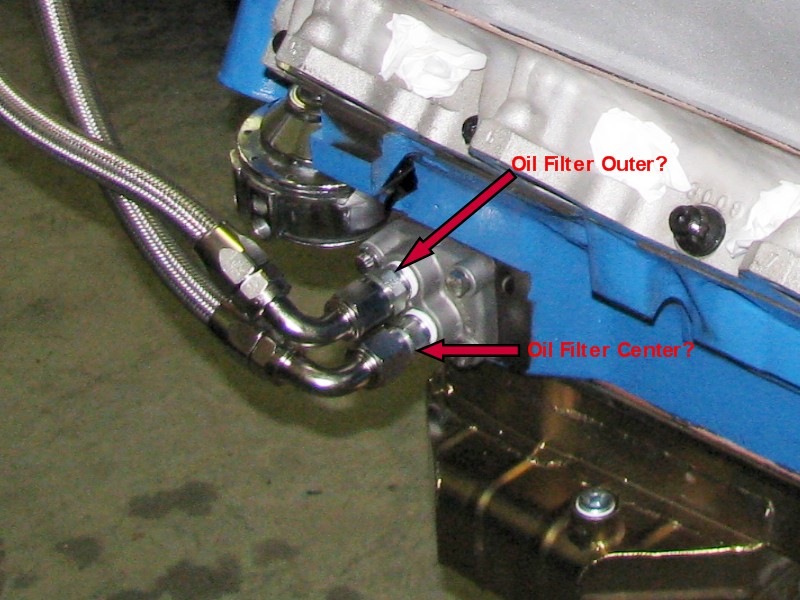

I couldn't find a definite answer for this, so will someone look at it a tell me whether I have the

oil routed correctly or not?

Now on to the headers. Considering how heavy these puppys are and how thick the flange is, they are some wavy, out of shape, heaps. I don't know if I'm going to be able to get #4 to seal w/o some surgery. What do you guys think?

Better view;

Someone really didn't want to be making FE headers that day I think. In this view with a straight edge, you can see that the flange is twisted on 3 axis. Not even close to straight;

That's it for now guys, Steve