How much clearance do you need?

I messed around quite a bit with my wheels to get the required caliper clearance. This is usually only a problem on rear wheels as front discs usually have plenty of setback to clear the calipers.

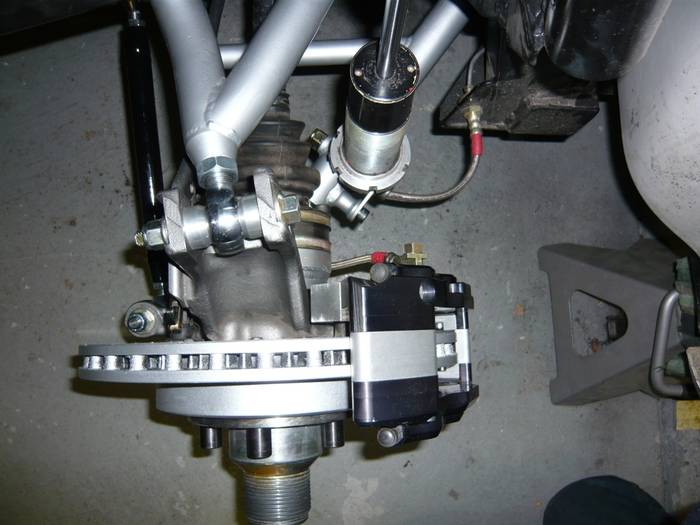

I put some 4 piston calipers and ventilated discs on the rear of my CR. Caliper to spoke clearance was going to be a problem. The calipers I bought were a low profile version so I gained about 8mm clearance over the regular model of this caliper.

When I got the wheels made I asked for the back of the spokes to be machined for clearance. With it all assembled I've got about 4mm of clearance between the outside face of the calipers and the spokes of the wheels. Just enough.

You should be able to gain a bit of clearance by machining the logo off the caliper and even take a bit off the outside face too. Disassemble the caliper and check the thickness of the body behind the piston. With the casting and production machining tolerances I reckon there will be a fair bit of material you could remove and still have plenty of thickness there.

If you have access to a Lathe big enough you could strip the tyres of the rear rims and machine a bit off the inside of the spokes. A mate of mine has a lathe that would do it but you are a bit far away.

I would pursue milling the caliper first as I reckon it's the easiest option.

Cheers