Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

6Likes 6Likes

07-16-2012, 12:39 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Is that the largest tuning fork ever made?

|

07-16-2012, 12:40 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

Is that the largest tuning fork ever made?

|

Excellent.  |

07-16-2012, 01:01 PM

|

|

Full Blown Member

|

|

|

Join Date: Sep 2008

Cobra Make, Engine: KMP 427 S/C, Twin Paxton 511 FE

Posts: 2,594

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

Is that the largest tuning fork ever made?

|

That's just like Patrick. Instead of letting the tuning fork vibrate, he found a way to strengthen it with those reinforcements.

__________________

rodneym

|

07-16-2012, 01:31 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

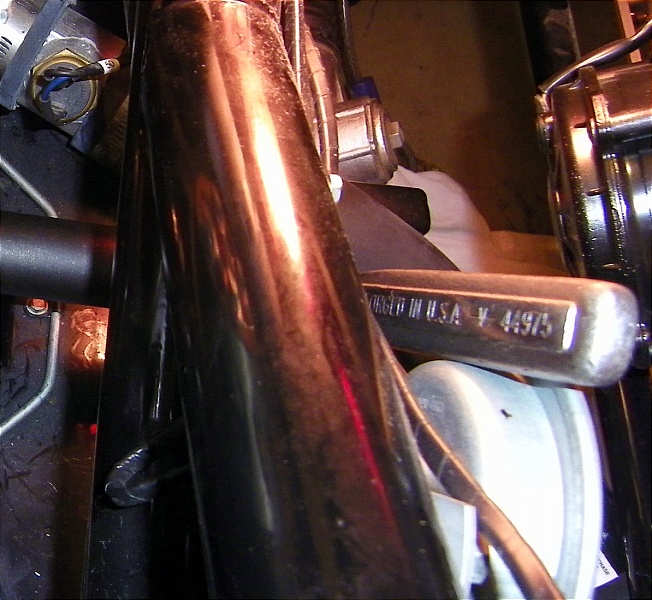

The Finest Wrench Ever Made...

The Finest Wrench Ever Made...

Chas. loves a close up shot of a tool, so here you go. Yep, this is a Vintage Oil Ball Craftsman 44975 1/2" Ratchet. I'm thinking you could probably lift both both Silverback and Chas., along with their bathtubs full of water, with this wrench.

Last edited by patrickt; 10-25-2016 at 09:46 AM..

|

07-16-2012, 04:09 PM

|

|

CC Member

|

|

|

Join Date: Jan 1999

Location: Bakersfield,

CA

Cobra Make, Engine: HI-TECH 289 FIA

Posts: 363

|

|

Not Ranked

Not Ranked

add onjThese fancy (expensive) tools are no better than the ones Finishline sold. the only reason for using a cheater bar on a C-man ratchet is they will replace it when you break it, and you will break it sooner or later.

I asked Lynn Parks (Trigo wheels) once about torque and his reply was,"Tight? MFT!" Thats "mighty f'in tight" in technical terms. The problem with hammers is potential fender damage and in the rear with deep wheels, half the stiking force is at a 45* angle to the intended direction of travel. Result is bent/broken spinner ears.

I can't afford silly tools, so I made my own. Cost near nothing and WILL remove

a stuck spinner. Thats a beetle jack supporting the outer end. The pipe on the business end was turned to fit the axle I. D.

__________________

fiaroadster

Last edited by Rick 427 Cobra; 07-16-2012 at 04:16 PM..

Reason: add on

|

07-16-2012, 04:44 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

FYI...... We torqued the wheels on the

Gt-1 Corvette and the Cobra to 600 lbs with BBS wheels ......with a 5 ft 3/4" Snap-on torque wrench....... And take them off with a 3/4" impact gun.

Always never-seeze the threads and the nuts or moly-coat the threads on the nut and spindle......nuts are Stainless and some are aluminum.

Great sound when you are tightening the nuts.......Klunk-Klunk.....takes two people to do it....

Morris

__________________

Morris

|

07-16-2012, 06:15 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Mike-LEAD, LEAD! Not brass.

You'll ruin a brass hammer and hurt the wheel when you miss.

Lead is best for those reasons.

It's not hard or expensive to use the right tool.

__________________

Chas.

|

07-16-2012, 06:46 PM

|

|

CC Member

|

|

|

Join Date: May 2012

Location: Blasdell,

NY

Cobra Make, Engine: Superformance, 408 Windsor

Posts: 125

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

Mike-LEAD, LEAD! Not brass.

You'll ruin a brass hammer and hurt the wheel when you miss.

Lead is best for those reasons.

It's not hard or expensive to use the right tool.  |

Gotcha... Cobra Valley's got a 6# for $39. Then I found this one from Cook, a 5# for $31: Cook Hammer Company Lead Hammers 117 5 5lb. hammer*::*HeavyDutyStore.com

__________________

Mike Glados

Blasdell, NY

|

07-16-2012, 08:03 PM

|

|

Senile Club Cobra Member

|

|

|

Join Date: Feb 2001

Location: Buffalo, NY USA,

NY

Cobra Make, Engine: Superformance

Posts: 4,566

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by MGlad

|

Cook makes the 6# hammers also, we sell them as the "BALK" (Big A$$ Lead Knockometer)

__________________

"I'm high all right, but on the real thing....powerful gasoline and a clean windshield..."

rick@autoventureusa.net

|

07-17-2012, 05:39 PM

|

|

CC Member

|

|

|

Join Date: May 2012

Location: Blasdell,

NY

Cobra Make, Engine: Superformance, 408 Windsor

Posts: 125

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Mark IV

Cook makes the 6# hammers also, we sell them as the "BALK" (Big A$$ Lead Knockometer)

|

Crap... didn't think about asking you about it.

__________________

Mike Glados

Blasdell, NY

|

07-16-2012, 06:51 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

^^^

__________________

Chas.

|

07-16-2012, 07:44 PM

|

|

CC Member

|

|

|

Join Date: Nov 2007

Location: Houston,

Tx.

Cobra Make, Engine: SPF #1235

Posts: 170

|

|

Not Ranked

Not Ranked

Get the 6# hammer. The extra weight helps.

__________________

Superformance #1235

460/T5

|

07-16-2012, 07:46 PM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: York Co. Maine USA,

ME

Cobra Make, Engine: ERA 427 S/C W/Holmon Moody Original Nascar build #508 Iron Block/heads (C5AE-H) Bal/Blu 427 Sideoiler; 780 Holley Dbl. Pump; 4 Speed Top Loader; AP Racing Bks; IRS; 15" Trigo pins

Posts: 391

|

|

Not Ranked

Not Ranked

Ohh! so fancy. Nice shinny tool!  I built my spinning tool with a 1/2" X 3 3/4" dia. steel plate; 3 equal sections of schedule 40 black iron pipe 1 1/2" depth by approx. 2" long. Placed the 3 equal parts on the 1/2" disk to fit in between each spinner fork, marked the disk & welded the pieces to the disk. Next I welded a 3/4" impact socket to the center of the back side of the disk. Smoothed the sched.40 blades to insure no damage to the spinners & then cut std. 3/8" fuel line 1 1/4" long & split on 1 side. To fit on to each side of the cut pipe/tool blades. It works the Balls!!  It also only cost about $10 to 15 bucks & a couple of hours labor. But my spinner tool isn't shinny  It's only painted flat black. But it does save the cost of a lead hammer every year or so! & allows for accurate torqueing of the spinners

Last edited by Silversmith; 07-16-2012 at 08:17 PM..

|

07-16-2012, 09:13 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,127

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Silversmith

Ohh! so fancy. Nice shinny tool!  I built my spinning tool with a 1/2" X 3 3/4" dia. steel plate; 3 equal sections of schedule 40 black iron pipe 1 1/2" depth by approx. 2" long. Placed the 3 equal parts on the 1/2" disk to fit in between each spinner fork, marked the disk & welded the pieces to the disk. Next I welded a 3/4" impact socket to the center of the back side of the disk. Smoothed the sched.40 blades to insure no damage to the spinners & then cut std. 3/8" fuel line 1 1/4" long & split on 1 side. To fit on to each side of the cut pipe/tool blades. It works the Balls!!  It also only cost about $10 to 15 bucks & a couple of hours labor. But my spinner tool isn't shinny  It's only painted flat black. But it does save the cost of a lead hammer every year or so! & allows for accurate torqueing of the spinners  |

If you can't document it, it didn't happen  ! Show us... please, so we can believe  .

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

07-17-2012, 11:24 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Allen,

TX

Cobra Make, Engine: Werk77 289FIA

Posts: 1,295

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Silversmith

Ohh! so fancy. Nice shinny tool!  I built my spinning tool ......  |

hehehe

__________________

Scratch build 289 FIA see the Scratch builder forum on CC - sold

DRB GT40 MK1 red #49- sold

FF5 Mk4 #7733 302/T5/IRS - dark blue - sold

FF5 MK4 #7812 427/TKO/IRS - Guardsman Blue - sold

FF5 MK4 #8414 501/TKO600/48IDA Ollie the Dragon #91 - sold

FF5 Daytona Coupe 347/TKO/IRS Homage CSX2299 Viking Blue - sold

SPF 2063

|

07-18-2012, 02:54 AM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Near Chichester, Sussex by the sea......,

UK

Cobra Make, Engine: Crendon 427 S/C 428 FE+toploader

Posts: 668

|

|

Not Ranked

Not Ranked

....hoping for a pic

....hoping for a pic

Quote:

Originally Posted by Silversmith

Ohh! so fancy. Nice shinny tool!  I built my spinning tool with a 1/2" X 3 3/4" dia. steel plate; 3 equal sections of schedule 40 black iron pipe 1 1/2" depth by approx. 2" long. Placed the 3 equal parts on the 1/2" disk to fit in between each spinner fork, marked the disk & welded the pieces to the disk. Next I welded a 3/4" impact socket to the center of the back side of the disk. Smoothed the sched.40 blades to insure no damage to the spinners & then cut std. 3/8" fuel line 1 1/4" long & split on 1 side. To fit on to each side of the cut pipe/tool blades. It works the Balls!!  It also only cost about $10 to 15 bucks & a couple of hours labor. But my spinner tool isn't shinny  It's only painted flat black. But it does save the cost of a lead hammer every year or so! & allows for accurate torqueing of the spinners  |

so am i right in guessing this is a steel disk, with 3 pieces of perpendicular tube welded on it, coated with rubber fuel pipe and a socket welded on the back?.... |

07-18-2012, 10:41 AM

|

|

Club Cobra Member

|

|

|

Join Date: Mar 2002

Location: arroyo grande, ca,

ca

Cobra Make, Engine: NAF 427

Posts: 1,774

|

|

Not Ranked

Not Ranked

This thread got me thinking so off to the tool store.

Found this large socket: 3 1/2" with 3/4" drive for $20.00. (see pics)

I'll have "slots" cut in it (see blacked out area on the socket) by a machine shop and edge the "slots" with hard nylon tubing to proctect the spinners.

I may add a "snout" in the center of the socket to go into the ID of the threaded hub to center the socket nicely.

I'll use a 3/4" drive 36'' long 300 ftlb torque wrench I bought on sale at Harbor Frieght a few years ago.

Just another idea.

Cheers

Greg

|

07-18-2012, 10:54 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by my427cobra

This thread got me thinking so off to the tool store...

|

Really? You know, in all of the years that I've been taking the wheels of my Cobra I have never had any problems taking them off or putting them on with the lead Muther Thumper 6lb hammer. OK, maybe once when I was also eating a sandwich and was hitting the spinner in the wrong direction.  I also have the stainless steel spinners, so I don't think I could break them if I tried. And my portable impact gun does not have enough "uummmphhhh" for these spinners anyway. I probably piss away more money on stupid tools than most people around here, but even I'm going to hold back on this stuff....  |

07-18-2012, 12:20 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by my427cobra

I'll use a 3/4" drive 36'' long 300 ftlb torque wrench I bought on sale at Harbor Frieght a few years ago.

|

Hey Greg, will you video that for us?  |

07-18-2012, 12:43 PM

|

|

Club Cobra Member

|

|

|

Join Date: Mar 2002

Location: arroyo grande, ca,

ca

Cobra Make, Engine: NAF 427

Posts: 1,774

|

|

Not Ranked

Not Ranked

I don't know. Maybe I will. Maybe I won't.

Any video's out there of someone using one of those BMF hammers? LOL

Cheers

Greg

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:19 PM.

Links monetized by VigLink

|