Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

16Likes 16Likes

06-19-2023, 07:02 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

And another hardtop project.

And another hardtop project.

Picked up the Butler hardtop a whole back that was for sale on here, and have finally gotten around to installing it. My car is a B&B and it is amazing how well the top fits. Had to tilt the windshield back a bit (Hey!! it's a B&B huh?) but the area in back fits nearly perfect and the sides will only take a bit of tweaking. I will need to machine up some pieces to fit into the soft top ferrules and will install some stainless steel over center clamps entering into the bottom of the ferrules to hold the rear of the top down. In front, the top came with come formed sheet metal pieces similar to the ones that attach a soft top. Think that I will use these and make a couple of stainless steel angle brackets to bolt to the top of them and epoxy to the underside of the hard top in the front. Question that I have for those of you versed in fiberglass work is: What kind of resin should I use? Haven't done any of this kind of work in about 30 years and have no idea what is on the market nowadays.

Thanx in advance and more pics coming.

|

06-20-2023, 03:06 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Clamps for the rear

Clamps for the rear

Just got these in and bent up to fit. They are going to work extremely well. The swingy thingy will enter the bottom of the ferrule for the top and clamp perfectly. All stainless, made in the USA and with standard threads. Making the aluminum blocks to epoxy to the hardtop now.   |

06-20-2023, 06:56 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

First job off the new lathe.

First job off the new lathe.

|

06-24-2023, 04:53 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Little more progress today, rear clamp assemblies.

Little more progress today, rear clamp assemblies.

Last edited by indianamoon; 06-24-2023 at 04:56 PM..

|

07-05-2023, 06:38 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

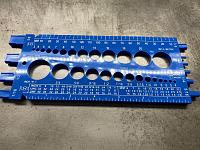

Stainless hardware

Stainless hardware

Well, all of the hardware for this project is going to be stainless, and the order showed up today.

For those of you looking for a decent source for stainless:

And they send you at no charge, one of these very cool gages for imperial and metric screws, bolts, nuts, etc.  |

07-05-2023, 06:51 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Unused stainless steel clamps for sale. Or trade

Unused stainless steel clamps for sale. Or trade

|

07-05-2023, 06:58 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Front windshield fitting, clamps, and glue thingie ready to go on.

Front windshield fitting, clamps, and glue thingie ready to go on.

|

07-09-2023, 05:26 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Front fittings glued and glassed in

Front fittings glued and glassed in

Mixed up a bit of epoxy, and with the front mounts securely in place with the clamps clamped, glued the formed stainless angle iron pieces to each side of the top. When that was cured, took it all apart and added a layer of glass cloth to both sides of the stainless angles. Looks like a lot of epoxy to me, but just to be safe, I drilled and installed two button head stainless screws on each side also.   |

07-09-2023, 05:44 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Time to fit the back of the top to the body

Time to fit the back of the top to the body

Alright, can't put this off any longer. The fit all across the back is as near perfect as I could hope for.  Fit on the passenger side is good enough to seal with the bulb seal.  However, (and I knew this) the fit on the driver side was just terrible, with a gap of at least 3/4 inch in places. Time to bend the fiberglass. Found a 4x4 and cut it to the contour of the bottom of the top as was.

Then scribed and did a matching angle cut to fit the pieces inside and outside the top at the flange.

Probably spent an hour with the belt sander getting the fit just about exact and then clamped everything up. Cut some small wedges to insert under the lip and started heating the lip of the top to about 375 degrees F. Worked it up and inserted the wedges, heated some more, wedges in further, until I had moved it about 3/4 inch where it needed to be.

Left it sit overnight and next morning the fit to the body was, while not perfect, certainly good enough for the seal to work properly

Last edited by indianamoon; 07-09-2023 at 05:57 PM..

|

07-09-2023, 05:54 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Rear mounts epoxied and glassed in

Rear mounts epoxied and glassed in

Got the rear mounts in today. Marked the top for location with everything in place, took it all off (for about the leventeenth time) glued the mounts in, and when that was cured, added a layer of glass cloth on each side of each block. With all the epoxy and the holes I drilled in the blocks, I am pretty certain that they will be going nowhere.

Now it is on to forming the rear window.

Last edited by indianamoon; 07-09-2023 at 05:58 PM..

|

07-10-2023, 12:05 AM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,129

|

|

Not Ranked

Not Ranked

Wow!

Wow!

That is impressive effort!

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

07-13-2023, 07:43 AM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Unexpected benefits

Unexpected benefits

Discovered that I can pin the rear mount over center clamps in the up position, keeping them off the bodywork when installing the top

|

07-17-2023, 01:13 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

PITA solution

PITA solution

Still moving forward with the installation. As I mentioned earlier, I had to pull the top of the windshield back about 2 inches. That necessitated moving that miserable little angle bracket on top of the dash. You know, the one with hardware that is so difficult to turn that you invent previously unheard swear word phrases to describe. Well, I was out of words, so ordered some teeny tiny stainless steel hex head machine screws to go into the bottom of the windshield frame. And some stainless phillips pan head sheet metal screws to go vertical into the top of the cowl. Knowing how hard it is to tighten these without a hole thru the windshield, I set them up in the mill and cut a hex on the head. Smiled all the way thru the installation 😃. I have more if anyone else needs their mood improved.   |

07-19-2023, 02:51 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Near Chichester, Sussex by the sea......,

UK

Cobra Make, Engine: Crendon 427 S/C 428 FE+toploader

Posts: 668

|

|

Not Ranked

Not Ranked

Interesting thread, and great work.

I bought a 289-style hardtop a few years ago. To fit the 427-style body, the roll bar and its rear leg, had to be cut into 4 pieces, new rear skirt to fit the 427 bodyshape and glassed back together. Prepped and painted it with 2k paint. Just finishing off the fixings, and will need to fix a few paint issues you can see here:

https://www.youtube.com/shorts/0B_9zDOgmKk

Heard these hardtop are notorious for leaking at the middle of the windscreen. To address this I bought a pair of standard soft top hood bows, pinged off the locator pins, and then cut a piece of curved channel to fill the gap between the 2 bows. I used polyurethane sealant/adhesive to fix these pieces together and to bond the hardtop to the bows. Some grp ribbon still to be added along the top to make sure it doesn't blow off t high speed.

If anyone's interested I can post some more, or start a new thread.

Last edited by KevinW; 07-19-2023 at 03:32 PM..

|

07-20-2023, 06:44 AM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Please post more, or a new thread. I would like to know more about sealing the front. I also have soft top front pieces incorporated in my installation. However, the front edge of the top doesn’t mate well with the top of the windshield. Difference shapes and with the textured outer face of the top, I decided to leave it as is. Picked up some different bulb trim for the front edge and will see how that works.

|

07-20-2023, 08:02 AM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: Copperhill,

TN

Cobra Make, Engine: Factory Five Racing, 306, E cam

Posts: 178

|

|

Not Ranked

Not Ranked

My hardtop experience is covered here.

Hardtop Project

For the front seal at the top of the windscreen, I'm using a 1/8 inch thick adhesive rubber seal that I found on Amazon. I haven't road tested it, but while fitting the top the imprint of the windscreen frame was pretty even all the way across, so I'm hopeful that it will seal pretty well.

Edit: Here's the seal

https://www.amazon.com/Neoprene-Weat..._rp_0_8_t&th=1

Last edited by john4337; 07-20-2023 at 11:42 AM..

|

07-21-2023, 08:32 AM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Near Chichester, Sussex by the sea......,

UK

Cobra Make, Engine: Crendon 427 S/C 428 FE+toploader

Posts: 668

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by indianamoon

Please post more, or a new thread. I would like to know more about sealing the front. I also have soft top front pieces incorporated in my installation. However, the front edge of the top doesn’t mate well with the top of the windshield. Difference shapes and with the textured outer face of the top, I decided to leave it as is. Picked up some different bulb trim for the front edge and will see how that works.

|

Thanks, will start a new thread when I get a bit more time work-wise.

Don't want to dog-leg the OPs great thread! |

07-21-2023, 05:38 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

And now the really dreaded part......

And now the really dreaded part......

|

08-02-2023, 06:02 AM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Near Chichester, Sussex by the sea......,

UK

Cobra Make, Engine: Crendon 427 S/C 428 FE+toploader

Posts: 668

|

|

Not Ranked

Not Ranked

I'm impressed. Interesting to hear how you applied heat. Blow torch?

|

08-02-2023, 04:50 PM

|

|

CC Member

|

|

|

Join Date: Jul 2013

Location: South Bend,

In

Cobra Make, Engine: B & B 289

Posts: 201

|

|

Not Ranked

Not Ranked

Industrial heat gun and took the temperature regularly.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:42 PM.

Links monetized by VigLink

|