Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

01-10-2009, 09:27 AM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: monroe,nc,us,

nc

Cobra Make, Engine: A&C 408 stroker

Posts: 33

|

|

Not Ranked

Not Ranked

I don't know which adapters you are talking about but three weeks ago I recieved a new set of Vintage wheels and adapters from Bob at Vintage everything bolted up perfectly although some pins with external hex heads would be nice, after reading about the problems about concentricity and taper I looked at mine, first I checked the taper, I put machinest blue dye on the pins and tightned them down,I had full contact (the taper appeared to be the same pin and hole) then I set up a dial indicator on a machined surface of the hub the most out of concentricity i could find is appx. .004-.006 all said I don't know about other wheel manufactures but the Vintage wheels were spot on, however the pins could be improved. When it is all worked out I will be in line for improved pins.

|

01-10-2009, 09:55 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by butz999

I don't know which adapters you are talking about but three weeks ago I recieved a new set of Vintage wheels and adapters from Bob at Vintage everything bolted up perfectly although some pins with external hex heads would be nice, after reading about the problems about concentricity and taper I looked at mine, first I checked the taper, I put machinest blue dye on the pins and tightned them down,I had full contact (the taper appeared to be the same pin and hole) then I set up a dial indicator on a machined surface of the hub the most out of concentricity i could find is appx. .004-.006 all said I don't know about other wheel manufactures but the Vintage wheels were spot on, however the pins could be improved. When it is all worked out I will be in line for improved pins.

|

I would not call 0.004-0.006 of an inch "spot on." Especially if we are talking about a hub. We hold our hub concentricity to under 0.001 inches. Modern automotive manufacturers hold concentricity in the microns on hubs.

Additionally, it is critical WHERE you take the measurement. If you took the measurement out at the OUTBOARD end of the hub (out at then end of the threads), it will not be the same next to the inboard side of the hub. Remember, a wobble of 0.006" at the inboard side of the hub could translate to substantially more out at the end of the hub--which may translate to who-knows-what out at the WHEEL. (Think of the distances involved.) Now think of the run-out of the rim and the run-out of the tire and add the whole mess together and your heart starts to pulse unevenly...not to mention the brakes too.

David

|

01-10-2009, 10:08 AM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: monroe,nc,us,

nc

Cobra Make, Engine: A&C 408 stroker

Posts: 33

|

|

Not Ranked

Not Ranked

What I am saying is the runout of the adapter matched the runout of the hubs, you are working with new piece by piece manufactured parts we are working with 30 year old stuf. My car is smooth as silk at any speeds I had it to. The vintage hubs were truely machined concentically.

|

01-10-2009, 10:26 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Unless you start measuring for runout @ the flange you are bolting the adapter to it's not possible to know whether the runout is the fault of the hub or other factors.

Craig

|

01-10-2009, 10:37 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Paul F

Great photos, very helpfull.

Must have a fantastic camera to take clear closeups like those.

It is interesting that we are all just getting into this after all the years of using adaptors.

Excellent thread.

Thanks Craig

|

01-10-2009, 12:04 PM

|

|

Senior ClubCobra Member

|

|

|

Join Date: Feb 2006

Location: Northern,

Ca

Cobra Make, Engine: LA Exotics

Posts: 1,038

|

|

Not Ranked

Not Ranked

Thanks Craig. It is a Nikon Coolpix S550 that has a macro mode that let's me get in very close. With 10Mpixels, I was able to blow it up further on a photo editor without it pixelating (is that a word?). I'm quite surprised and pleased with the results. First time I used the macro.

I agree about the pin drive discussion. When we settle down on this, I want to bring up a similar discussion about the spinners.

|

01-10-2009, 12:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Gents:

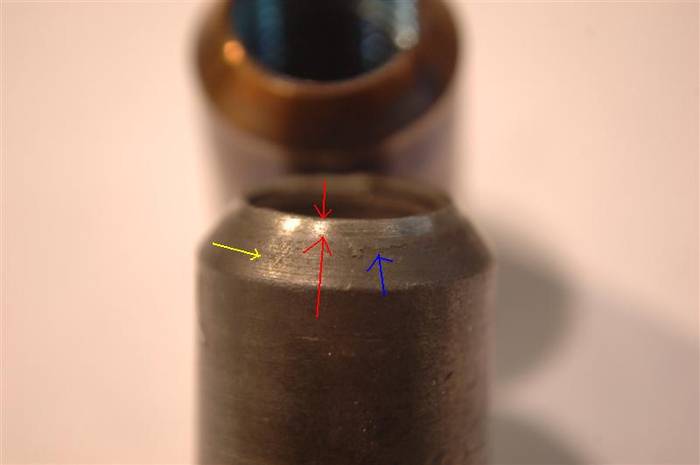

Paul F. kindly sent me this pin. This, I think, is what started the whole discussion. Notice the cracks...this death deserves an autopsy. You never know what you'll find.

For clarity, this is Compomotive part. I am beginning to think Compomotive and Trigo got these nuts from the same place because the measure out the same and look the same.

David

Last edited by David Kirkham; 01-10-2009 at 12:16 PM..

|

01-10-2009, 12:15 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is the other side of the pin. Notice the fine tapered edge is quite ragged. Between the arrows, there is a part of the taper that is actually missing.

Last edited by David Kirkham; 01-10-2009 at 12:20 PM..

|

01-10-2009, 12:27 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

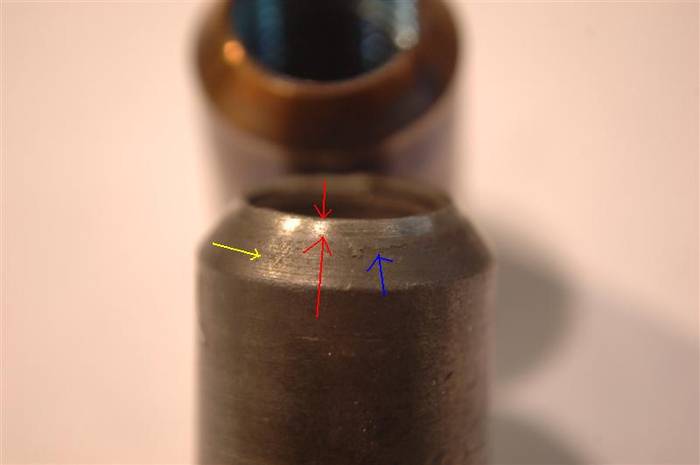

Now, things get interesting.

Between the red arrows, you can see a bright, shiny ring that goes all the way around the very end of the pin. That ring is where the black oxide coating has been scraped off the pin as it was tightened into the hub adapter.

That ring is the ONLY contact point where the male taper of the pin contacts the female taper of the hub adapter. Notice it does NOT make full contact.

|

01-10-2009, 12:29 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

The yellow arrow shows the machining marks from the lathe that was used to make the taper.

|

01-10-2009, 01:30 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Ashburton, New Zealand,

..

Cobra Make, Engine: UK Ram SC. KC-Yates 373, Jerico 5 speed.

Posts: 1,240

|

|

Not Ranked

Not Ranked

Pin drive bolts

Pin drive bolts

David brilliant job, I normally look indepth at components to see if they are engineered correctly, but wouldnt have thought to on the pin drive nuts.

We have machined all our hubs from 4140 front being similar to original with press in pins and retaining nuts so not a problem there, but on the rear we made adapters similar to Trigo, I tested the Trigo adapters before I sold them and they are just normal soft free machining steel from memory so I wasnt happy with them even though that type of steel is probably adequate for the job.

I am using Cap screws and the Trigo Pin drive bolts on the rear, but now have major concerns with the small seating ring area, and I have had two of these trigo pins have approx 3/32" chunks of metal break off the inner sharp taper just with assembly maybe the metal is quite hard or brittle!

I will consider machining the correct taper or making new ones, we used to make them with two flats which isnt as nice to work with as the internal 12pt or if anyone is supplying a better product I would be interested.

__________________

A J. Newton

The 1960's rocked!

|

01-10-2009, 02:03 PM

|

|

Senior ClubCobra Member

|

|

|

Join Date: Feb 2006

Location: Northern,

Ca

Cobra Make, Engine: LA Exotics

Posts: 1,038

|

|

Not Ranked

Not Ranked

Uggh! I didn't look at the pins. Of the other 4 I have, two have several fractures on the non-taper side. There are no fractures on the taper side.

David, looking at the picture of the hub in my previous post, do you think Trigo and Compomotive hubs come from the same vendor?

I'm thinking they both buy pins from one vendor and hubs from another vendor, but don't spec the parts. Thus the mis-match. Just a guess.

|

01-10-2009, 02:17 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Paul F

Uggh! I didn't look at the pins. Of the other 4 I have, two have several fractures on the non-taper side. There are no fractures on the taper side.

David, looking at the picture of the hub in my previous post, do you think Trigo and Compomotive hubs come from the same vendor?

I'm thinking they both buy pins from one vendor and hubs from another vendor, but don't spec the parts. Thus the mis-match. Just a guess.

|

Not sure if the Compomotive and Trigos come from the same vendor. I would have to see them side by side.

As for the mis-match on tapers...I can think of no reason why anyone would make a 76 degree taper? It simply makes no sense to me. I think someone had a quality control issue.

David

|

01-10-2009, 02:14 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Ant

David brilliant job, I normally look indepth at components to see if they are engineered correctly, but wouldnt have thought to on the pin drive nuts.

We have machined all our hubs from 4140 front being similar to original with press in pins and retaining nuts so not a problem there, but on the rear we made adapters similar to Trigo, I tested the Trigo adapters before I sold them and they are just normal soft free machining steel from memory so I wasnt happy with them even though that type of steel is probably adequate for the job.

I am using Cap screws and the Trigo Pin drive bolts on the rear, but now have major concerns with the small seating ring area, and I have had two of these trigo pins have approx 3/32" chunks of metal break off the inner sharp taper just with assembly maybe the metal is quite hard or brittle!

I will consider machining the correct taper or making new ones, we used to make them with two flats which isnt as nice to work with as the internal 12pt or if anyone is supplying a better product I would be interested.

|

Ant,

Hard does not always equate to brittle. Think of a really high quality steel that is properly heat treated. I once saw a F1 1/2 shaft from a crash that was bent at 90 degrees! It didn't break! It didn't even have a crack. But, that junk "free machining steel," "leaded steel," and other such abominations can be quite soft and the lead inclusions will make it brittle. Perhaps that is why we have seen so many of the threads torn and broken. I would have to do a chem and hardness on the pins, but I don't know if I want to spend the 100 bucks on the test.

As for making you pins, that is no problem.

David

|

01-11-2009, 12:08 AM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Ashburton, New Zealand,

..

Cobra Make, Engine: UK Ram SC. KC-Yates 373, Jerico 5 speed.

Posts: 1,240

|

|

Not Ranked

Not Ranked

Pin drive bolts.

Pin drive bolts.

David,

thanks for your experience, that makes sense, and with the quality of your cars the right metal for each job is so important, as you mention hard can still equate to elasticity.

Will keep an eye on this post, and when suitable I would like some pins made.

My hubs are drilled for 1/2" which could have been 3/8" but I am stuck with that size! Interestingly enough I was looking at some single seater race cars Lola T332 and others they have a thin drive flange and piddly little drive pins transmitting 500bhp through their massive rear tires, but they are quite light, so its how the car is engineered.

Quote:

Originally Posted by David Kirkham

Ant,

Hard does not always equate to brittle. Think of a really high quality steel that is properly heat treated. I once saw a F1 1/2 shaft from a crash that was bent at 90 degrees! It didn't break! It didn't even have a crack. But, that junk "free machining steel," "leaded steel," and other such abominations can be quite soft and the lead inclusions will make it brittle. Perhaps that is why we have seen so many of the threads torn and broken. I would have to do a chem and hardness on the pins, but I don't know if I want to spend the 100 bucks on the test.

As for making you pins, that is no problem.

David

|

__________________

A J. Newton

The 1960's rocked!

|

01-10-2009, 09:53 PM

|

|

Super Moderator

|

|

|

Join Date: May 2001

Location: Fresno,

CA

Cobra Make, Engine: KMP 184/482ci Shelby

Posts: 14,448

|

|

Not Ranked

Not Ranked

ahem................

__________________

Jamo

|

01-10-2009, 11:03 PM

|

|

Senior ClubCobra Member

|

|

|

Join Date: Feb 2006

Location: Northern,

Ca

Cobra Make, Engine: LA Exotics

Posts: 1,038

|

|

Not Ranked

Not Ranked

Quoting David: ps. Isn't your "other set of good holes" for a different bolt pattern???

Me: D'oh!

I'd still like to buy 22 pins if you're still selling them.

|

01-12-2009, 12:54 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Paul F

I'd still like to buy 22 pins if you're still selling them.

|

Paul,

The first batch will be coming out today. Pics coming up.

David

|

01-12-2009, 12:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Ant,

I'll post some more interesting pics in a bit. The problems these pins face are pretty complex.

David

|

01-12-2009, 12:53 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jamo

ahem................

|

We still love you. You just make such a nice object lesson...

David

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:20 AM.

Links monetized by VigLink

|