Yours:

Quote:

|

Originally Posted by Fordfan69

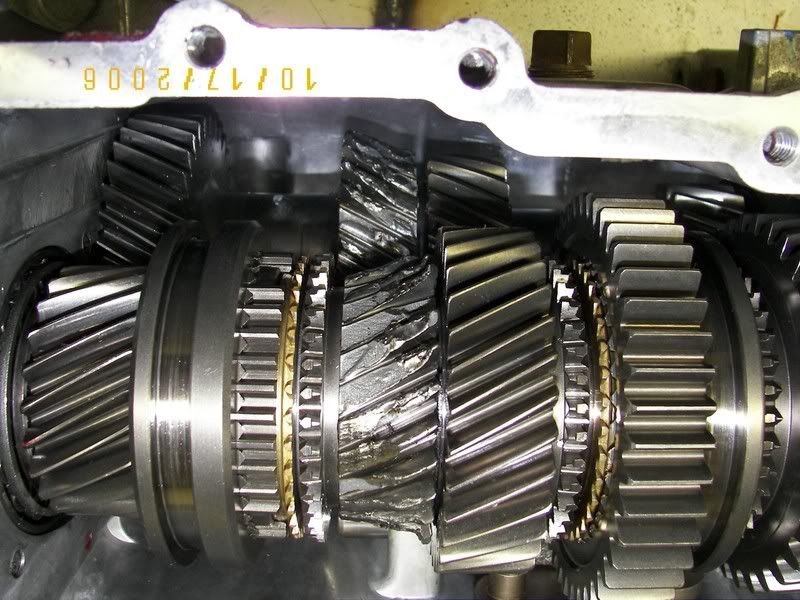

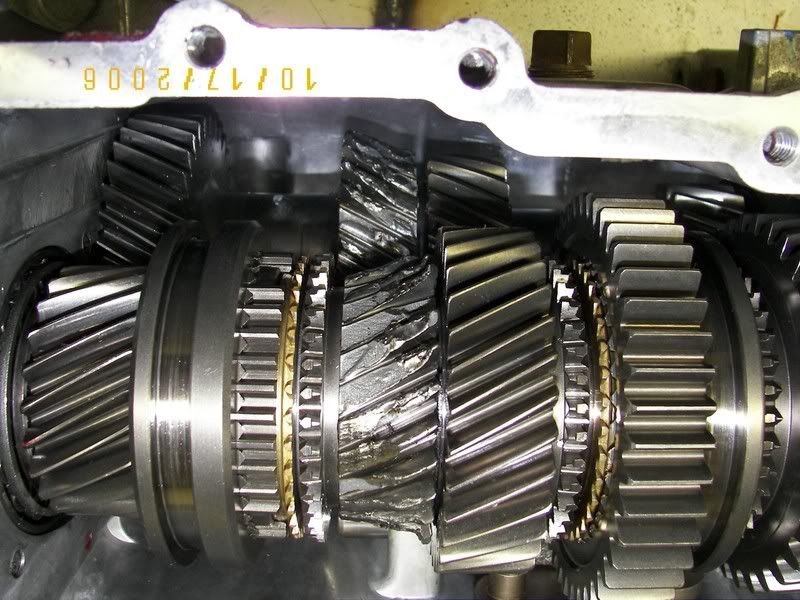

3. Every single knowledgealbe and even not-so knowledgeable people that I have shown the gears to absolutely said it must have been some sort of a part failure or improper installation (gear meshing not right). I am the first one to admit that I am in no way perfect, but I and others looked very hard and I also thought back to the moment very hard and there is not a doubt in my mind that I did not miss that shift. I've attached another picture showing more clearly 3rd gear's dog teeth and synchro blocker. They are in excellent shape. The shape of ones that came out of a box with only slightly more than 1000 miles on them.

If I wasn't in the gear all the way or missed the shift, the dog teeth would be damaged and/or rounded. Not the case.

If any damage would occur from improper usage, as they say, wouldn't it be to the dog teeth. How is it possible that they are mint. That tells me and others that the synchro hub was fully engaged to the 3rd gear. I am not saying that Keisler assembled the tranny incorrectly, but there is something wrong for the main teeth to fail in that way on that angle opposite that of the cluster gear.

4. Another reason why I felt this failure was not a failure of my own doing is due to the fact that I found another user of the Tremec 5speed that also had a failure. When I looked at his picture, It looked almost identical to mine. The teeth sheared off on the same angles and all. Another reason why I thought it might be a part failure. You can see his picture and read his post if you want at http://www.pro-touring.com/forum/showthread.php?t=23218

. |

I think you're right. The "gears" are always in constant mesh, when you shift, it is the slider sleeve, or whatever you want to call it, that moves and engages the small synchro teeth on the gear, with the brass blocking ring bringing the gears up to similar speeds for engagement of the synchro teeth.

Because the main gear teeth are angled, the front of the tooth will always engage the counter gear tooth first, before the rear of the tooth, thus initially placing the load on the front of the tooth, both on the main gear and on the counter shaft. If the 3rd gear ojn the counter shaft is larger than the 3rd gear on the main shaft, then that may be why the front part of the teeth on the main gear sheared, as they be weaker relative to the 3rd gear on the counter gear. Maybe that's why the front of the teeth are broken more than the rear, and the opposite on the counter gear.

If you miss a shift, it usually damages the small synchro teeth, not the larger main teeth. Actually, when buying a used trany, it's usually the small synchro teeth that are worn or bad, and often overlooked by the prospective buyer, and the main teeth look fine, but the tranny is really hosed because of the poor synchro teeth condition.

Quote:

|

Originally Posted by rj8806

.... The evidence speaks for itself. The gear was sheared off in the front of the gear. If there was a defect in the material, the outcome would have been different.

This is a mute point anyway as Tremec has inspected it too and came to the same conclusion we did, abuse. They will not warranty it for that reason.

Richard

Tech Support

Keisler Engineering

|

I think the evidence does speak for itself. If it was 1/2 into gear, the synchro teeth would be half sheared, not the main drive teeth, as they never move, i.e. slide forard or backwards, the slider sleeve does. I've rebuilt several muncies and toploaders, and they're basically the same design, all the gears are always in constant mesh, while in any gear. It's the slider sleeves engaging or disengaging the synchro teeth that determine how power is transfered, between which gears. Have you rebuilt any trannies, or understand how they work?

Quote:

|

Originally Posted by scott coyle

Tremec had issues in the past with the case expanding on 3550's when the tranny is loaded, and third gear breaks. If you add in a heavy car(dodge) and the difference between second and third gear ratio's, they are far apart, it looks like it loaded the tranny, the case expanded and the teeth snapped off.

First and second are pretty low gears, so even in a heavy vehicle, they usually won't break. 4th gear is direct, so it won't load the tranny. Thats why third gear breaks. In a cobra, the vehicle is so light, the tranny is not really loaded as much as a heavier vehicle, so breakage is less likely.

|

Excellent explanation and it sounds logical. If the case expands alittle, the main gears get alittle out of alignment, and the load is not evenly placed on the teeth of the main gears, shearing off the front of the teeth first, as that is the part of the tooth that engages first. The other possibility is gear weakness, or poor design ( teeth angle too much, or gear diameter too small)

Interesting failure.

Threaded Mode

Threaded Mode