RJCCOBRA

Wed January 21, 2009 3:46pm

Rating: 1

|

Shell Valley build

The hood was bowed and warped so badly that we had to cut slots in the inner panel, fill with foam, and then add weight to level out the passenger's side. After the foam hardened, we put a layer of glass over the cuts and added weight again.

|

|

Ron61

Mon January 26, 2009 12:12pm

Rating: 10

|

Lawns outside Legislature Building....

|

|

dont

Thu February 19, 2009 11:39am

|

side pipes

Tig welding the new classic chambered 3" ID mufflers onto existing collector and turn out

|

|

Bernica

Wed February 25, 2009 12:24pm

|

Test Run at Santa Anita Race Track

Nice big parking lot to get some run time. That is, of course, until security catches you and runs you out!

|

|

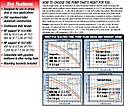

kitcarbp

Fri February 27, 2009 8:45am

Rating: 10

|

Edelbrock Fuel Pump Curve for my 1791 street-duty pump

Taken from the Edelbrock Web-Site, check it out.

|

|

Dwight

Mon March 2, 2009 6:51pm

|

428 Q Code motor

428 motor out of a '67 (Q) wagon "S" Code block

|

|

Dwight

Mon March 2, 2009 6:51pm

|

428 Q Code motor

428 motor out of a '67 (Q) wagon "S" Code block

|

|

Clois Harlan

Mon March 9, 2009 6:32pm

|

HCS Body side shot

Notice the outer skin of the door is still taped in place for final fitments and then the adhesive will be applied to make it one piece.

|

|

Clois Harlan

Mon March 9, 2009 6:32pm

|

Full shot of HCS Coupe

I know the picture is dark but I forgot to allow my flash on this shot but you can see how well the body has came out of the mold.

|

|

Clois Harlan

Mon March 9, 2009 6:33pm

|

Dash

Looking from the trun this is the dash and the quick release steering wheel. Just wait until we get the inside finished out with the best gauges on the market ...definetly high end!

|

|

cobra25

Wed March 11, 2009 10:48am

Rating: 10

|

CSX 4990

Out from a little winter hibernation

|

|

Plums

Sun March 15, 2009 5:41am

|

Emily showing off my new plates.

Bolting the plates on and stuff falling out of the sidepipes....

|

|

kitcarbp

Thu March 19, 2009 10:30am

Rating: 10

|

500+ HP Engine Water Jacket Coolant Flow Requirements

This chart shows the linear relationship between the heat rejection (load) of the coolant and the required (calculated) coolant flow in the engine water jacket. It is determined for 3 different temp gradients of the engine inlet and outlet coolant temp. This engine example is from a 500+ horsepower supercharged gas engine assumed to have heat rejection up to maximum power (8,000 btu/min). Why do we care? If you cant keep engine temps under control at speed under load, you may have: 1) insufficient water flow, 2) undersized radiator, or 3) insufficient air flow through the radiator that needs to be addressed. This engine will require coolant flow in the lower part of the curve in street applications (low heat rejection), but for racing/track use this engine will require coolant flow rates towards the top of each curve. For older V8's pre-emissions, the common design target is to keep the radiator Inlet @ 190 F and outlet @ 180F or an average core temp of 185F at steady state conditions or the upper curve shown. Modern engines may use a little higher 195F-185F or rad core avg temp of 190F.

|

|

DocDirk

Sun March 22, 2009 4:18pm

|

|

DocDirk

Sun March 29, 2009 7:07pm

|

Upholstered!

Just out of the upholstering shop, nice to have my toy back!

|

|