I wish I would have said -

1) in plan, the rear upright has to be able to rotate about it's vertical axis in both clockwise (anti-squat) and counter clockwise (toe) directions. Can't do it with hard bushings.

2) hard mounting the cradle requires that the assembly tolerances are quite good from ERA. Mine are - YMMV

I can see how this could go bad - cradle not square to chassis.

We started final fit of the cradle and rear suspension. Next week we will square it to the front and try to understand the 16.5 trailing arm length and will know just how square the cradle is to the chassis.

Trying to understand the 16.5 dim with respect to the wheelbase. I will call ERA but would like to understand as much as I can before I call them.

Trailing link @ 15.5 Wheelbase @ 90. Top link in double shear.

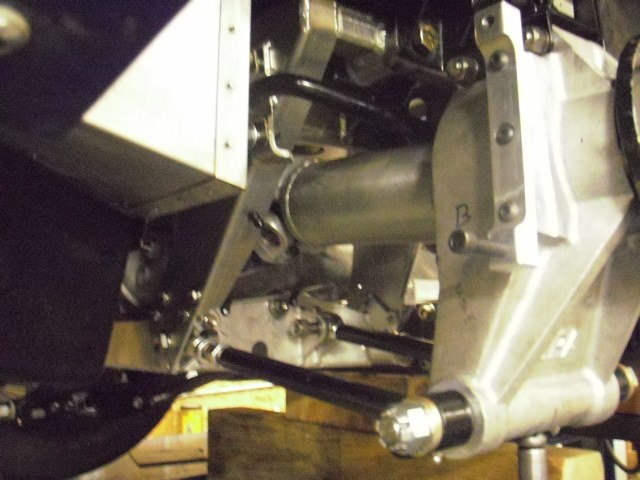

Urethane bushings reinstalled at upright - Delrin @ top of cradle

This is the pivot we are concerned with. There is .100 total gap left after rod end is inserted. If trailing link is too long this link is pushed back against the cradle. Any reward motion and the un-tapered portion of the rod end hits the cradle. We are building spacers to center the rod end in the mount.This will allow the link to rotate thru the bearing and hopefully not kiss the cradle. We are going to relieve a little material at the cradle to assure the un-tapered portion of the rod end does not touch.

Fuel line passage - Delrin at cradle front. With the top secure the front mounts rested against the cross member with no load. Bolts were threaded by hand. Very impressive ERA.

We bump stopped the front and increased track .250 per side. Since we are fabbing new arms I took it. With the front control arms horizontal, ground clearance at front of chassis = 4.250

Bump = 1.625

Droop = 1.875.

So with the front geometry square we've dropped the CG .500.

Start milling link spacers next week.