Quote:

Originally Posted by bobcowan

What you need is more pressure, and the same volume.

A bigger piston bore will move more volume. BUT, it will require more pedal pressure to create the same pressure. And that pressure will be created in a shorter piston stroke. Anything more than 1" in a manual system will create a very hard pedal, and a short stroke.

A smaller bore will work better for you. Changing the stroke of the piston will have nothing to do with pedel effort. You can change the leverage by changing the pedal ratio.

I would not ( and do not) use a "proportioning valve". What most people call a proportioning valve is really a pressure reduction valve. It doesn't really proportion anything.

Stock cars come from the factory with a combination valve. Part of it's function is to help balance the brakes. They're very carefully designed to work in a variety of situations. AFAIK, there are off the shelf combination valves that will work in a car like this.

PEDAL RATIO: One of the big points from the Hot Rod Heaven web site was the pedal ratio. That appears to be the #1 reason for a hard pedal and poor braking. For a manual system, you want to get at least 6:1, and preferably 7-7.5:1. Anything less will require a large amount of pedal pressure to produce enough line pressure to stop the car.

Measure the distance from the brake pedal pivot point and the center of the pad, where your foot goes. Now measure the distance from the pedal pivot point to the push rod attachment point. Divide one into the other, and that's your ratio.

The other issue is the arc that the brake pedal and push rod move through. The push rod is a straight fore and aft movement. But the brake pedal moves in an arc - and so does the push rod attachment point.

Look at your pedal from the side. If the pedal is straight up and down, that means your rod attachment point is probably at the 6 o'clock position at rest. As you move the pedal forward, the push rod end moves in an upward arc, with less forward motion the further you depress the pedal.

I put a 7* dog leg in my brake pedal. That keeps the pad where it's supposed to be, but moves the push rod attachment point closer to the 4 o'clock position. My artistic skills are not that good, but this might make it more clear.

Before spending any money on any MC, evaluate your pedal ratio and position. This could be a very simple fix. |

Thanks so much for all that info, Bob....hope I can provide some info that is helpful.

Thanks for the explanation of the difference between bores. I can get a 1" bore, even found a 7/8" bore at some other source. I'll abandon the idea that more volume is the answer, pressure rules, I see!

Re: the proportioning valve...I keep hearing that if you lock the brakes up, the first should be the fronts, as the car swaps ends easily if the rear brakes lock up first. Would the valve I mentioned, which probably does reduce pressure as you said it would, reduce the tendency to lock up the rear brakes first? If not, would I just get some factory "combination valve"? There is nothing in the lines now that I can see, but I have yet to get under the car and trace brake fluid lines yet.

Pedal ratio....yeah...the pedal system is obviously homemade, here are a few pics:

A photo of the brake pedal from near the trans tunnel:

There does appear to be a mechanism for adjustment of the pedal position...you can see in this next photo that there is another hole in the bracket that fixes the position of the brake pedal that would allow the pedal to be appropriately placed for someone with longer legs. The current placement is just fine for me, though:

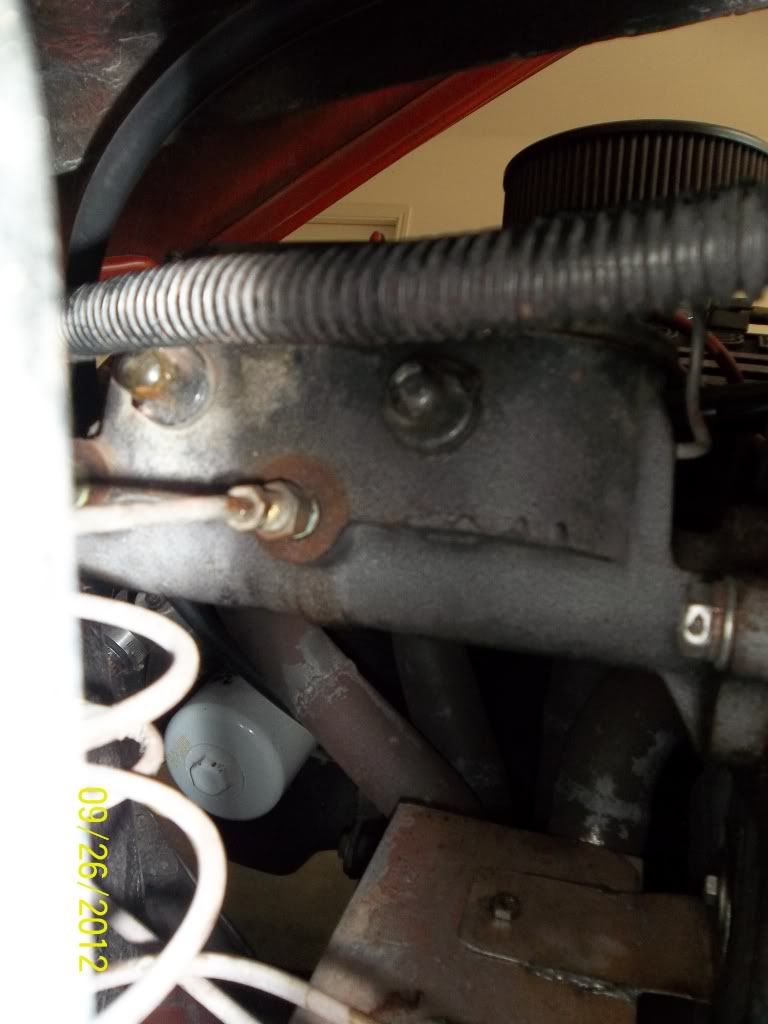

Here is a photo of the current MC (I can see a trail of leaking brake fluid):

Another photo of the same from a bit of a different angle, note that the brake lines attach on the fender side of the MC:

A shot taken through the driver's side fender vent:

Here's an issue that bothers me....I can see brake fluid on the inside of the firewall when I look forward under the dash, and now that I got a photo of the MC area I can see the trail of leaking brake fluid leading downward from the engine side of the firewall. I see that the large reservoir is down on fluid (again)...no need to wonder where the fluid is going now:

I will get under the car tomorrow to see if I can get those measurements you want for the pedal ratio...not sure how I could modify it, though...and not sure I am ready to tackle that job again...I had the pedal box assembly off once before, when I had to change the clutch cable, and it was a 3 day job. The Cobra is my only transportation right now, so I can't afford to be without a car for 3 days....maybe a weekend, but the local welding shop is closed on weekends, so there I am back at being without a car on a workday....[sigh]!

Thanks, Bob and all, for all your help. Right now I think I may just replace the MC with a similar 1" bore model...and approach a wholesale change of the pedal mechanism when I have more time and $$

.

Cheers!

Dugly