Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

08-31-2012, 03:46 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

Need help with master cylinder theory/operation, please.

Need help with master cylinder theory/operation, please.

I want to improve the braking performance on my Cobra replica.

Currently it is fitted with Wilwood disc brakes all around, no power assist and not room to fit one.

I think the way to go is to replace the Master Cylinder. I have a Bendix master cylinder right now....can't figure out the number from the photo, but nobody seems to be able to cross over the # on the gasket for the top, so maybe it is not a current model.

So, if I want to improve my brake function, would I look for a master cylinder with greater piston diameter or lesser piston diameter, given the same stroke dimension for the piston? It would seem to be greater volume would be the way to go, but when I read the Tech Tips on the Wilwood site it said greater pressure should be achieved with a smaller piston diameter.

Seems contradictory to me....obviously I do not understand how brakes work. I would appreciate some information on brake theory and also some tips regarding which changes to pursue. Of course, there is no history on the car to indicate what the application was for regarding the current master cylinder, so I'll have to remove it and measure the bore diameter and go from there.

Thanks, guys 'n' gals.....I'm trying to avoid having to buy the ultra-high cost Wilwood master cylinders, I don't race the car, just street use, but things do get pretty hot on the freeways in the Houston area and I know heat affects braking performance. I can rebuild the calipers if need be, and if I were to attempt any significant performance upgrade would certainly do so. Right now the brakes work OK, just not like I would prefer!

Cheers!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

|

-

Advertising

08-31-2012, 04:04 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

F=P/A Force = Pressure/Area

If you want more pressure you use a master with a smaller bore. The downside to that is it requires a longer stroke to move the volume to fill the calipers. Get as many measurements as you can off the length of pedal arms, pivots, master and slave sizes. I can send you an Excel spreadsheet I put together that does the math for you if you just put numbers in. There are some online calculators available also.

|

08-31-2012, 04:37 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

F=P/A Force = Pressure/Area

If you want more pressure you use a master with a smaller bore. The downside to that is it requires a longer stroke to move the volume to fill the calipers. Get as many measurements as you can off the length of pedal arms, pivots, master and slave sizes. I can send you an Excel spreadsheet I put together that does the math for you if you just put numbers in. There are some online calculators available also.

|

08-31-2012, 04:37 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,455

|

|

Not Ranked

Not Ranked

This page will give you an excellent explanation of how it all works together: Brake Article© by Dean Oshiro

For a MC, I highly recommend something like this:

I use 3/4" for front and rear. The calipers are also Wilwoods - 6 piston fronts and 4 piston rears. I think you get much better performance and balance with a MC like these, because it's much easier to adjust the balance. Most Roadsters need more rear bias than the average car, and so off the shelf single MC's are not really built for that.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

08-31-2012, 06:04 PM

|

|

CC Member

|

|

|

Join Date: Jan 2002

Location: Northridge,

CA

Cobra Make, Engine: Arntz Cobra

Posts: 1,839

|

|

Not Ranked

Not Ranked

Dugley,

I have literally spent years working on that exact problem with my Cobra. I have also very nearly killed myself testing the brakes. I have a bunch of Wilwood master cylinders and lot of other parts that didn't work out in a cabinet. Some day when I retire, I'll try to sell them on eBay.

The master cylinder is not your problem. It is the brake pads. Some pads grip the rotors more aggressively than others. New pads almost never grip and take a few hundred miles to wear in and start working well. A lot of them will work for a while, then lose their grip as they age. I have tried lots of brake pads. I have found that Ferodo pads will fit my Jaguar rear calipers with Kurt Hamilton's vented rotors and lock up the rears pretty well. I cannot find Ferodo pads to fit my front calipers. I have tried many other brands and am currently using Porterfield's. These grip reliabily and never fade.

The simple fact is, that without power assist on the front brakes, it takes a LOT of leg to stop a Cobra. I could not find the right combination to enable my leg lock up all four wheels. I have Wilwood balance bar and two master cylinders with an adjustment knob so that I can adjust the bias from front to rear. I can vividly describe how quickly a Cobra will spin around if your rear brakes lock up before the fronts. It is very scary and could easily kill you. This is to be avoided at all costs.

I have not been able to find the right combination of components to lock up my Cobra's wide sticky front tires (Mickey Thompson 255/60/15's) without power assist. The front tires of a car do 80 to 90 percent of the work to stop the car. Many Cobra's and hot rods are been fitted with some form of power assist for this reason. I use a vacuum powered remote brake booster mounted in front of my engine to do the job. Like the one in this article: http://www.race-dezert.com/forum/sho...e-Booster-Pics. It is not pretty, but it works really well. However, that's not the whole story. With my new engine's hydraulic roller cam, I have a lot of vacuum and too much front brake bias. So, I also had to install a Wilwood adjustable proportioning valve. With that, I can set the booster's maximum pressure so that I can balance the brakes. There are also hydraulic brake boosters that use power from a car's power steering pump to help apply pressure, but I don't have power steering. Someday, when I have an extra $1,200, I will buy an electric brake booster like this: http://www.speedwaymotors.com/Electr...Disc,8335.html.

To adjust the brake bias, I waited for the right day when we had a good rain shower (that stopped) to take my car to a big parking lot. On wet pavement I don't flat spot the tires. I get the car up to about 30 and turn the wheel into a gentle turn then hit the brakes really hard. If the car spins around, you have too much rear bias. If it straightens out, you have too much front bias. If it slides at an angle you have it just right. It has to do that in both directions.

The final chapter is about the brake bias adjuster. If I'm on a rally, the gas tank is full and my Co driver’s 240 pound butt is in the car, it goes all the way to the rear and the rear's still do not lock up. If I am autocrossing alone with a light fuel load, I move to it to the center and keep working it between runs to get it exactly right. I hope this helps you.

RS

__________________

"It doesn't have anything on it that doesn't make it go faster."

Last edited by RallySnake; 08-31-2012 at 06:11 PM..

|

08-31-2012, 07:32 PM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Cobra Make, Engine:

Posts: 773

|

|

Not Ranked

Not Ranked

Some basics. Smaller bore size equals more line pressure. Suggested MC size, 1inch to rear, 7/8 inch to rear. Use the shortest, braided brake lines from the hard lines to the calipers as possible. Use a bias adjuster-easy with a dual MC system. Have 100lbs more pressure to front than rear. Adjust from here. You do not want the rear to lock up before the front. I use a gauge that is hard plumbed in the system to know pressures for sure. An inline dual piston MC will require a bias valve. A lot of kit cars don't use any bias valve. Big mistake. And when they do most are from a donor car which in most cases will not be set up properly for the weight and bias of a Cobra.

One of the biggest mistakes is to not bed in the brakes properly from the start. Make sure all of the protective oil has been removed from the rotors to start with. With new brakes go out and at 40 - 50 mph hit the brakes hard, bring the car to a stop-just short of locking them up. Do this 5-6 times. You should smell the pads. Bring the car in and let it cool completely. The purpose of this is to bed the pad particles into the rotors. If you don't do this from the start the brakes will never be as good as they can be.

I have floor mounted pedals which generally have a lower leverage ratio than hanging pedals. I have no problem locking the fronts. I run 275/18s.

Also, if your MCs are floor mounted and are lower than the calipers, you will want to use residual valves. These keep the fluid from draining out of the MC. if this happens your pedal will have a lot of travel before they move enough fluid to fill the calipers back up. Install the residual valves as close to the MC as possible. 2# valves for disc brakes, 10# for drum brakes.

Good brakes are a must. It's worth the time and effort to get them sorted out. Good luck.

|

09-26-2012, 08:43 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

Suggestions for choice...two MC options, which one is what I need?

Suggestions for choice...two MC options, which one is what I need?

Quote:

Originally Posted by bobcowan

|

I've tried your link multiple times, also copied the URL and pasted it into my browser window, can't get it to connect...even added an "l" at the end believing it was an html attachment..sure would like to read it, though, Bob!

I've had the car out to a rod builder who has a reputation for doing the best brake work in the area, and after looking at my setup his first bit of advice was to get a "Corvette" type master cylinder. I see the difference between the one I have and the Corvette type, the 'Vette type has two equal sized reservoirs in the master cylinder while mine has a large reservoir closest to the firewall and a smaller reservoir at the front of the master cylinder. Since this is a manual brake system, it makes sense to me that the reservoirs (and, hopefully by extension, the volume of fluid moved when the brakes are pressed) would need to be equal.

I don't think there's any way to adjust the length of travel of the piston. Since I don't know much about brake theory, I'm at a loss for what to do now. Logic tells me that in order to more effectively clamp the disc pads against the disc, more volume of fluid needs to be moved when the brake pedal is pressed. If that is right, I have found a 1 1/8" bore 'Vette style MC at Speedway Motors, see this:

Power/Manual Master Cylinder, 1-1/8 Inch Bore - Speedway Motors, America's Oldest Speed Shop

However, if a smaller bore is better (keeping in mind that there is no way for me to adjust the "leverage" by increasing the stroke of the piston), Speedway also offers this 1" bore model:

Power/Manual Master Cylinder, 1 Inch Bore - Speedway Motors, America's Oldest Speed Shop

I think the MC needs to be replaced, regardless....I think it is leaking into the footbox from where the piston rod enters the MC and replacement of the carpeting is waiting to get that issue resolved.

These are both said to be appropriate for both manual and power brakes, and mine are going to have to remain manual, so I guess my only confusion is which bore to buy.

Would the 1" bore offer greater clamping pressure and therefore better braking, or do I need to get the larger 1 1/8" bore MC?

Either way, a proportioning valve will be sourced and installed into the brake line leading to the rear of the vehicle....I don't want the car swapping ends if I put the brakes on, and on wet roads this lightweight car with 11" wide rear tires hydroplanes VERY easily, so I'm wary of that issue!

So confused.........so  that I don't understand this, I'm usually very competent regarding mechanical issues and this one is evading understanding.

Thanks, guys, for whatever help you can give me!!!

Cheers!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

Last edited by YerDugliness; 09-26-2012 at 08:45 AM..

|

09-26-2012, 09:05 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Dadeville,

AL

Cobra Make, Engine: Sold my EM.

Posts: 2,459

|

|

Not Ranked

Not Ranked

You have a private message.

__________________

Tommy

Cheetah tribute completed 2021 (TommysCars.Weebly.com)

Previously owned EM Cobra

"Never attribute to malice that which is adequately explained by stupidity." - Hanlon's Razor

|

09-26-2012, 09:24 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Atlanta,

GA

Cobra Make, Engine: 86 Everett Morrison 90" WB. 428 FE

Posts: 1,151

|

|

Not Ranked

Not Ranked

A proportioning valve will not work. It only limits the rears without moving the needed force to the fronts. A balance bar with side by side master cylinders is the way to go with a smaller bore. Bigger diameter rotors, more cylinder area in the calipers, less in the master a longer pedal and balance bar all add to the good.

Look at it this way. If a 110 Lbs. woman stepped on you with the back of a flat. Then the same woman stepped on you with spiked heels. Which would hurt more? A smaller bore equals a higher psi. Smaller bore are the spiked heels!

Then again there's power assist brakes, but I think you'll like those spiked heels.

Ralphy

__________________

What?

Last edited by Ralphy; 09-26-2012 at 09:55 AM..

|

09-26-2012, 09:34 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Share Share Share......

This is a interesting topic

Dugly,

In order to get your brakes right there is a lot of information that is needed. As you can see some have made correct suggestions but it is the holistic view of the brake system that will make your car stop.

Is this a tandem MC that you are using?

What size pistons in the front calipers?

What size pistons in the rear calipers?

What are your line pressures front / Rear?

Are your pedals floor mounted?

What is your pedal ratio?

Are you using a balance bar?

Do you have a proportioning valve?

How much force are you looking to apply to lock up your brakes?

How much force are you looking to apply to stop the car normally

What pads are you using?

These are just some specs that are needed to get you started?

|

09-26-2012, 10:24 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Tommy

You have a private message.

|

Replied, thank you, Tommy

Quote:

Originally Posted by Ralphy

A proportioning valve will not work. It only limits the rears without moving the needed force to the fronts. A balance bar with side by side master cylinders is the way to go with a smaller bore. Bigger diameter rotors, more cylinder area in the calipers, less in the master a longer pedal and balance bar all add to the good.

Ralphy

|

Thanks for that, too, Ralphy. I don't think a major change to the braking system is in the works at this time. I need to try to make do with a single dual-reservoir master cylinder if at all possible.

Please keep your eyes out for new posts on this thread....I will get the wheels off the Cobra and take some photos....perhaps that will help.

Thanks again....great analagy with the spike heels!

Quote:

Originally Posted by priobe

Share Share Share......

This is a interesting topic

Dugly,

In order to get your brakes right there is a lot of information that is needed. As you can see some have made correct suggestions but it is the holistic view of the brake system that will make your car stop.

Is this a tandem MC that you are using?

What size pistons in the front calipers?

What size pistons in the rear calipers?

What are your line pressures front / Rear?

Are your pedals floor mounted?

What is your pedal ratio?

Are you using a balance bar?

Do you have a proportioning valve?

How much force are you looking to apply to lock up your brakes?

How much force are you looking to apply to stop the car normally

What pads are you using?

These are just some specs that are needed to get you started?

|

By tandem, if you mean one with two reservoirs, yes, that is the present setup.

As for piston sizes, I will need to do some research. I know the brakes are Wilwoods, but other than that I haven't really done much deeper investigation.

The pedal is hung from the firewall under the dash, not floor mounted.

There is no balance bar, no proportioning valve yet. The rod-shop proprietor mentioned that when I get the new master cylinder on I would need one in the line to the rear brakes to keep them from locking up before the front brakes, and the MC's to which I posted links both have ports on both sides. Would there be any advantage to using both ports from the front reservoir and the rear reservoir over using one port and pluggine the other off?

As for front/rear line pressures, I have no idea...what sort of gauge would be necessary to measure these spec's?

Force...it takes some pretty stout pressure on the brake pedal to get the brakes to lock up right now, but when I do the fronts lock up first, IIRC. I really haven't had to test them in real-life yet.

The type of pads are unknown to me....I bought the car as it is and have put 5,000 miles on it and the brake pads look to be in great shape, not excessively worn or unevenly worn. It has never not stopped, but there were a few times I was glad to have the shoulder to use to avoid the car in front should it have been necessary. I drive a lot in the rush hour traffic in Houston, so I need good brakes and my hope is to improve on those on the car right now....I don't plan on racing the car, it is 100% street use only.

As I mentioned in my reply to Ralphy, I will get the car up on jackstands and get the wheels off, take some photos so perhaps the answers to some of these questions can be ascertained, and post again, hopefully later today.

Thanks to all who have pitched in! Stay tuned, I'll have more information soon!

Cheers!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

Last edited by YerDugliness; 09-26-2012 at 10:35 AM..

|

09-26-2012, 04:59 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,455

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by YerDugliness

I've tried your link multiple times, also copied the URL and pasted it into my browser window, can't get it to connect...even added an "l" at the end believing it was an html attachment..sure would like to read it, though, Bob!

|

I checked out that web site before I posted it. But when I look for it now, the entire HotRodHeaven web site appears to be non-existant. Too bad, as that was some of the best information on brakes I'v come across in a long time.

Quote:

Originally Posted by YerDugliness

I see the difference between the one I have and the Corvette type, the 'Vette type has two equal sized reservoirs in the master cylinder while mine has a large reservoir closest to the firewall and a smaller reservoir at the front of the master cylinder. Since this is a manual brake system, it makes sense to me that the reservoirs (and, hopefully by extension, the volume of fluid moved when the brakes are pressed) would need to be equal.

|

Many stock MC's have a bigger resevoir and bore on one end than the other. Those are generally designed for cars with disc front and drum rear brakes. Drum brakes require less volume.

Quote:

Originally Posted by YerDugliness

I don't think there's any way to adjust the length of travel of the piston. Since I don't know much about brake theory, I'm at a loss for what to do now. Logic tells me that in order to more effectively clamp the disc pads against the disc, more volume of fluid needs to be moved when the brake pedal is pressed. If that is right, I have found a 1 1/8" bore 'Vette style MC at Speedway Motors, see this:

|

Not exactly. What you need is more pressure, and the same volume.

A bigger piston bore will move more volume. BUT, it will require more pedal pressure to create the same pressure. And that pressure will be created in a shorter piston stroke. Anything more than 1" in a manual system will create a very hard pedal, and a short stroke.

Quote:

Originally Posted by YerDugliness

However, if a smaller bore is better (keeping in mind that there is no way for me to adjust the "leverage" by increasing the stroke of the piston), Speedway also offers this 1" bore model:

|

A smaller bore will work better for you. Changing the stroke of the piston will have nothing to do with pedel effort. You can change the leverage by changing the pedal ratio. More on that later.

Quote:

Originally Posted by YerDugliness

I think the MC needs to be replaced, regardless....

|

I agree. I think it should be replaced with a dual MC like I pictured above. If I thought there was anything better on the market, I'd be using it.

Quote:

Originally Posted by YerDugliness

Either way, a proportioning valve will be sourced and installed into the brake line leading to the rear of the vehicle....

Dugly  |

I would not ( and do not) use a "proportioning valve". What most people call a proportioning valve is really a pressure reduction valve. It doesn't really proportion anything.

Stock cars come from the factory with a combination valve. Part of it's function is to help balance the brakes. They're very carefully designed to work in a variety of situations. AFAIK, there are off the shelf combination valves that will work in a car like this.

PEDAL RATIO: One of the big points from the Hot Rod Heaven web site was the pedal ratio. That appears to be the #1 reason for a hard pedal and poor braking. For a manual system, you want to get at least 6:1, and preferably 7-7.5:1. Anything less will require a large amount of pedal pressure to produce enough line pressure to stop the car.

Measure the distance from the brake pedal pivot point and the center of the pad, where your foot goes. Now measure the distance from the pedal pivot point to the push rod attachment point. Divide one into the other, and that's your ratio.

The other issue is the arc that the brake pedal and push rod move through. The push rod is a straight fore and aft movement. But the brake pedal moves in an arc - and so does the push rod attachment point.

Look at your pedal from the side. If the pedal is straight up and down, that means your rod attachment point is probably at the 6 o'clock position at rest. As you move the pedal forward, the push rod end moves in an upward arc, with less forward motion the further you depress the pedal.

I put a 7* dog leg in my brake pedal. That keeps the pad where it's supposed to be, but moves the push rod attachment point closer to the 4 o'clock position. My artistic skills are not that good, but this might make it more clear.

Before spending any money on any MC, evaluate your pedal ratio and position. This could be a very simple fix.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

09-26-2012, 05:18 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

More info with pics!

More info with pics!

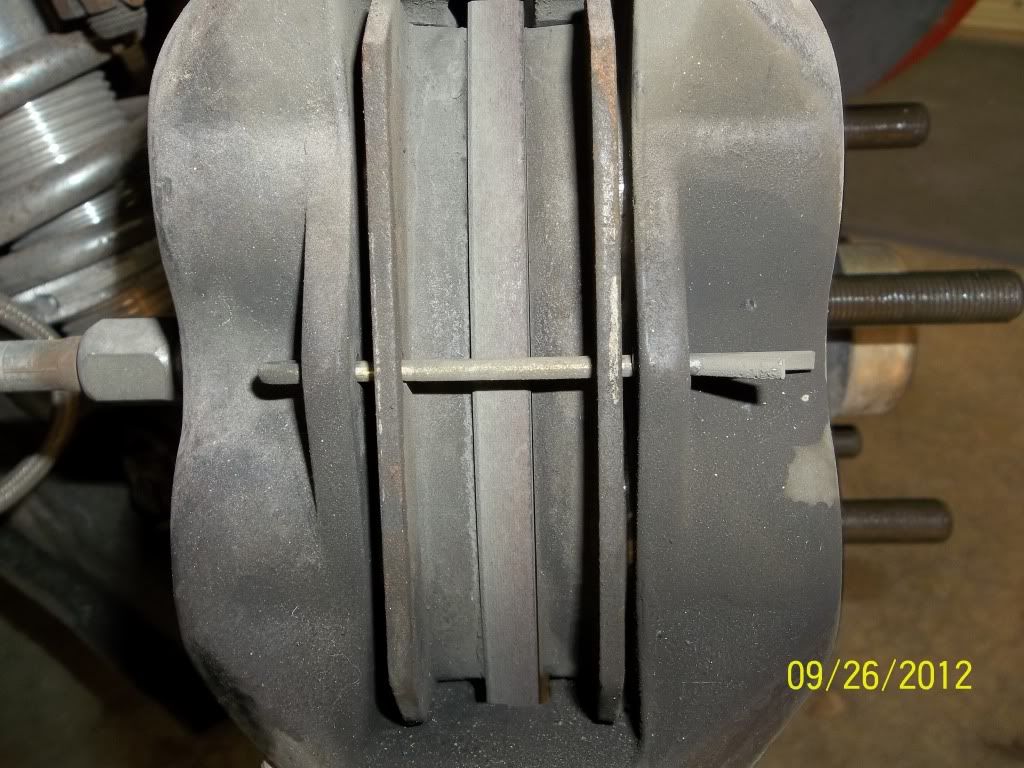

I have been able to get the Cobra on jackstands and take photos. It appears the front and rear calipers are identical, with one exception. The front calipers have 4 pistons (2 inner/2 outer) and have this number on the inside half of the caliper: 120-1051. The rear calipers have 4 pistons, also (2 inner/2 outer) and have an ALMOST identical number on the inside half of the caliper: CA 120-1051. Both the front and rear seem to have similar construction and appear to bleed similarly, also. Here are some photos:

Here's a photo of the front caliper:

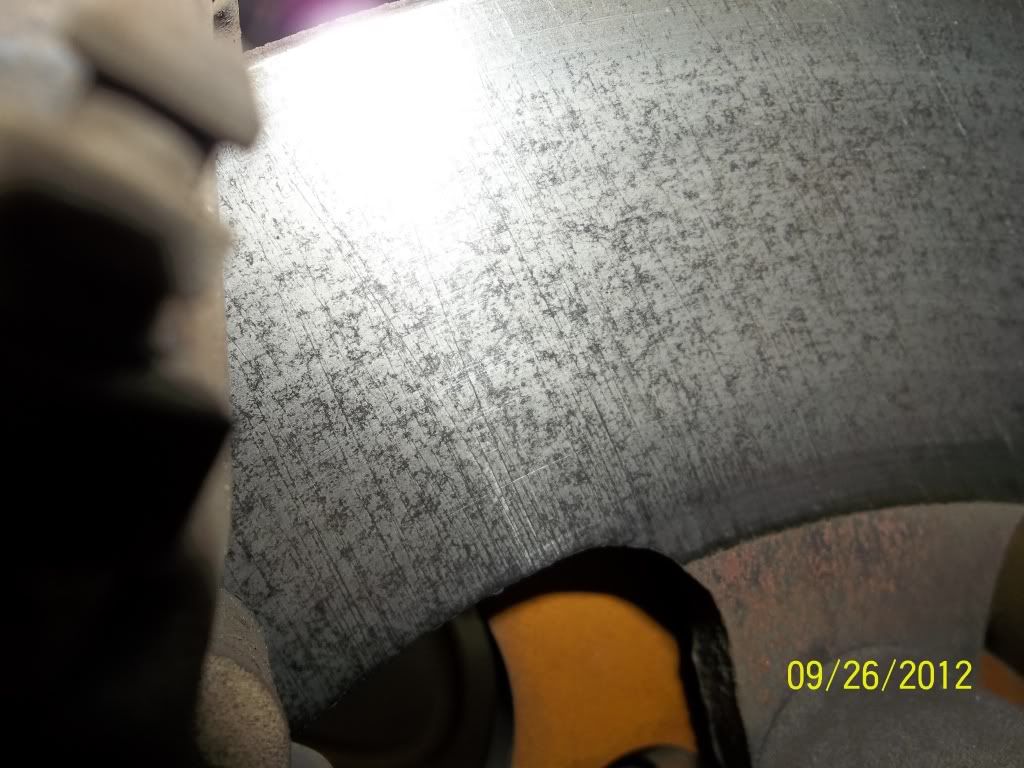

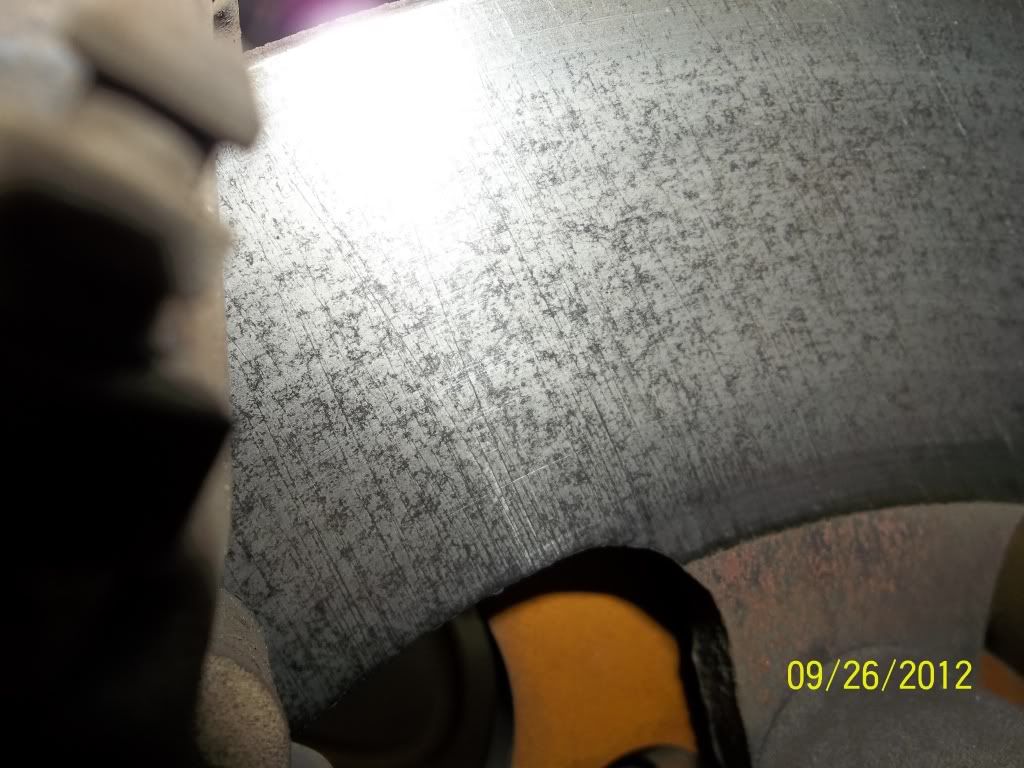

A shot of the rotor (looks OK, no scoring):

A closer shot of the caliper:

A photo taken from underneath, showing the crossover tube:

A photo from behind, showing the flex-line...looks like quality stuff:

A shot from the top, showing the bleed valves:

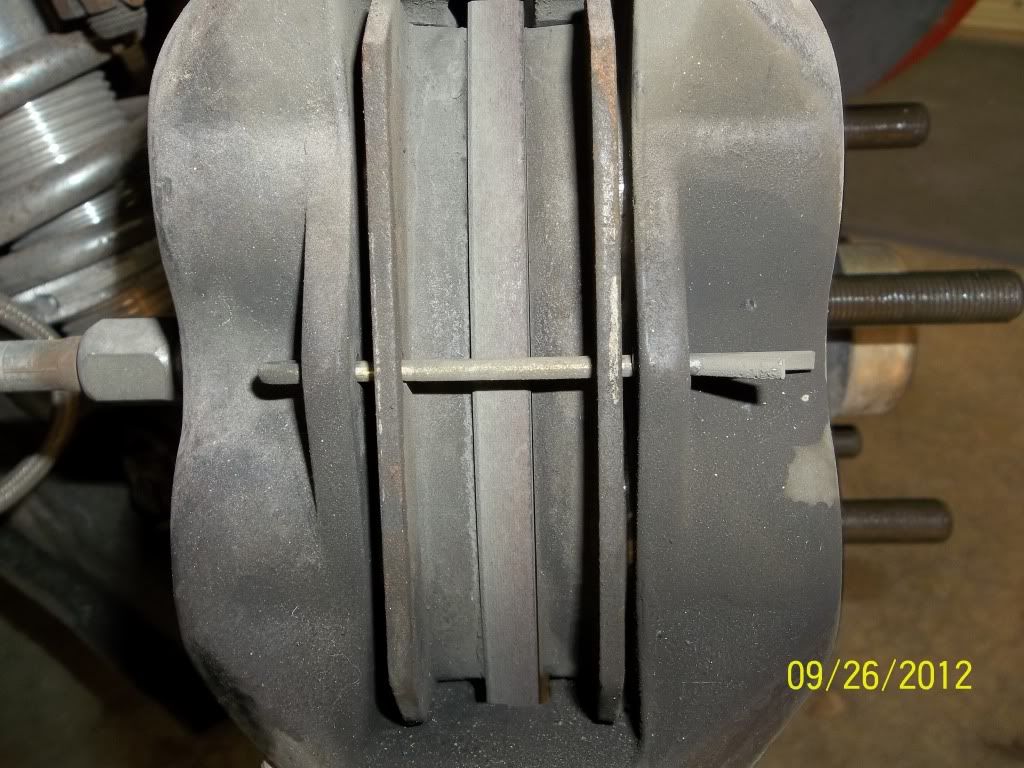

Here's a shot of the pads, they look good:

Blurry, I know, but the only numbers I can find on the front calipers (120-1051):

Here is the rear setup:

A closeup of the caliper (other than the "CA", it seems identical in every respect to the front calipers):

And, finally, a shot of the pads...again, not much wear evident:

I will post this, then get a shot of the master cylinder, if that will help.

Cheers!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

|

09-26-2012, 06:06 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by bobcowan

What you need is more pressure, and the same volume.

A bigger piston bore will move more volume. BUT, it will require more pedal pressure to create the same pressure. And that pressure will be created in a shorter piston stroke. Anything more than 1" in a manual system will create a very hard pedal, and a short stroke.

A smaller bore will work better for you. Changing the stroke of the piston will have nothing to do with pedel effort. You can change the leverage by changing the pedal ratio.

I would not ( and do not) use a "proportioning valve". What most people call a proportioning valve is really a pressure reduction valve. It doesn't really proportion anything.

Stock cars come from the factory with a combination valve. Part of it's function is to help balance the brakes. They're very carefully designed to work in a variety of situations. AFAIK, there are off the shelf combination valves that will work in a car like this.

PEDAL RATIO: One of the big points from the Hot Rod Heaven web site was the pedal ratio. That appears to be the #1 reason for a hard pedal and poor braking. For a manual system, you want to get at least 6:1, and preferably 7-7.5:1. Anything less will require a large amount of pedal pressure to produce enough line pressure to stop the car.

Measure the distance from the brake pedal pivot point and the center of the pad, where your foot goes. Now measure the distance from the pedal pivot point to the push rod attachment point. Divide one into the other, and that's your ratio.

The other issue is the arc that the brake pedal and push rod move through. The push rod is a straight fore and aft movement. But the brake pedal moves in an arc - and so does the push rod attachment point.

Look at your pedal from the side. If the pedal is straight up and down, that means your rod attachment point is probably at the 6 o'clock position at rest. As you move the pedal forward, the push rod end moves in an upward arc, with less forward motion the further you depress the pedal.

I put a 7* dog leg in my brake pedal. That keeps the pad where it's supposed to be, but moves the push rod attachment point closer to the 4 o'clock position. My artistic skills are not that good, but this might make it more clear.

Before spending any money on any MC, evaluate your pedal ratio and position. This could be a very simple fix. |

Thanks so much for all that info, Bob....hope I can provide some info that is helpful.

Thanks for the explanation of the difference between bores. I can get a 1" bore, even found a 7/8" bore at some other source. I'll abandon the idea that more volume is the answer, pressure rules, I see!

Re: the proportioning valve...I keep hearing that if you lock the brakes up, the first should be the fronts, as the car swaps ends easily if the rear brakes lock up first. Would the valve I mentioned, which probably does reduce pressure as you said it would, reduce the tendency to lock up the rear brakes first? If not, would I just get some factory "combination valve"? There is nothing in the lines now that I can see, but I have yet to get under the car and trace brake fluid lines yet.

Pedal ratio....yeah...the pedal system is obviously homemade, here are a few pics:

A photo of the brake pedal from near the trans tunnel:

There does appear to be a mechanism for adjustment of the pedal position...you can see in this next photo that there is another hole in the bracket that fixes the position of the brake pedal that would allow the pedal to be appropriately placed for someone with longer legs. The current placement is just fine for me, though:

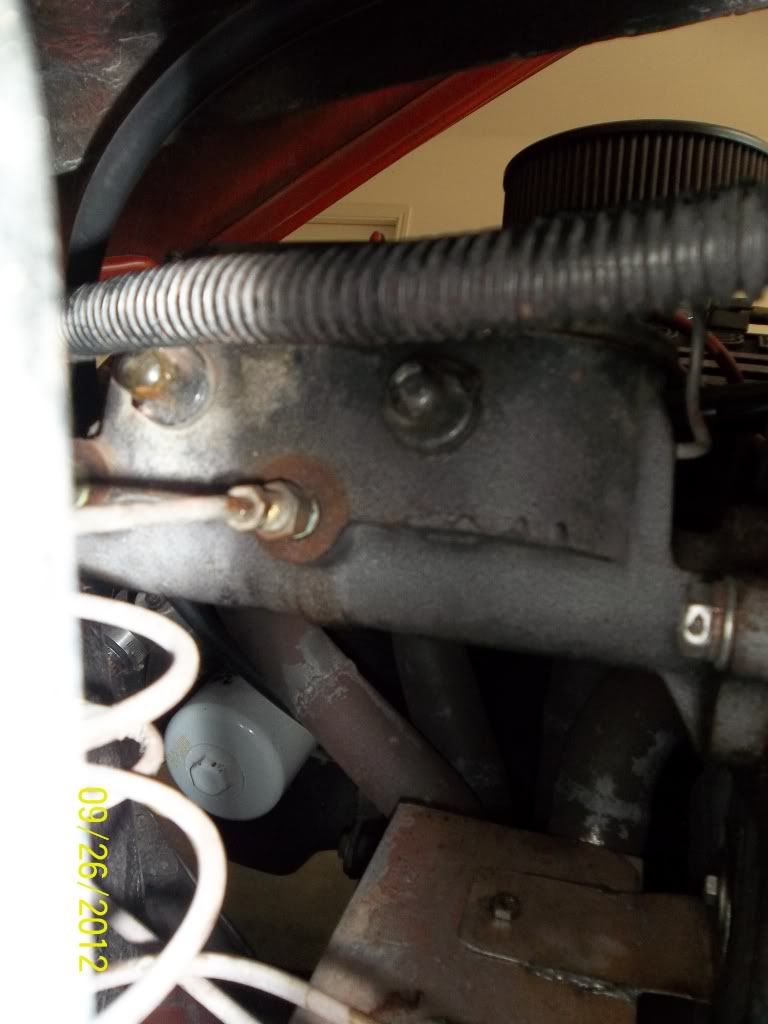

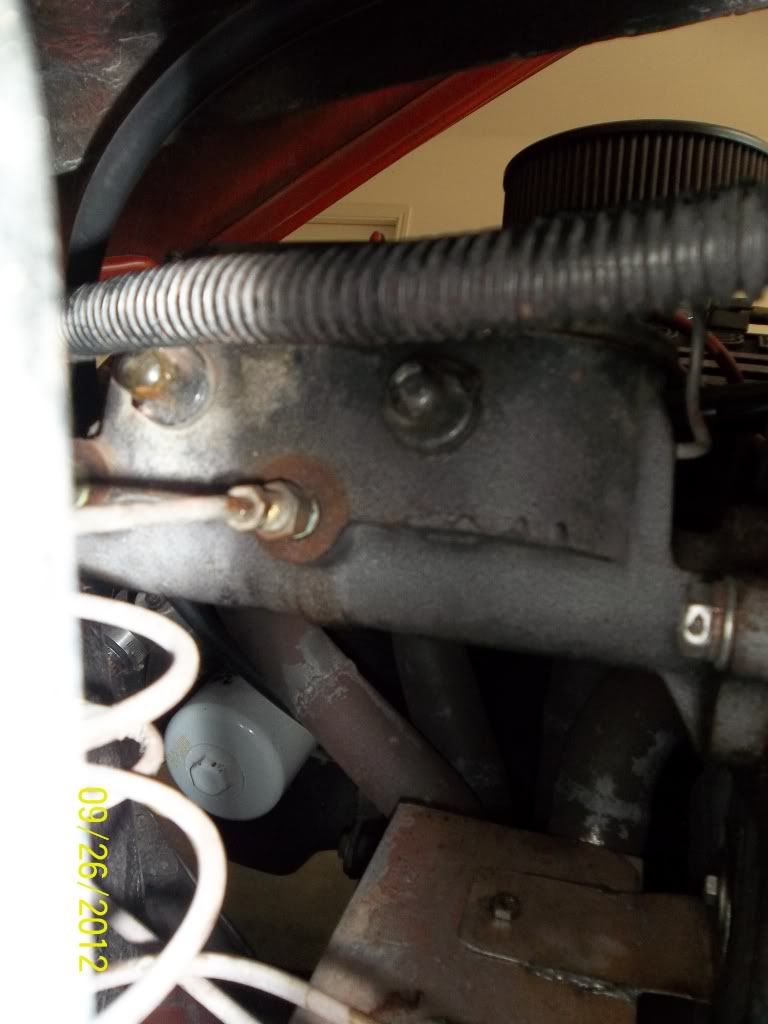

Here is a photo of the current MC (I can see a trail of leaking brake fluid):

Another photo of the same from a bit of a different angle, note that the brake lines attach on the fender side of the MC:

A shot taken through the driver's side fender vent:

Here's an issue that bothers me....I can see brake fluid on the inside of the firewall when I look forward under the dash, and now that I got a photo of the MC area I can see the trail of leaking brake fluid leading downward from the engine side of the firewall. I see that the large reservoir is down on fluid (again)...no need to wonder where the fluid is going now:

I will get under the car tomorrow to see if I can get those measurements you want for the pedal ratio...not sure how I could modify it, though...and not sure I am ready to tackle that job again...I had the pedal box assembly off once before, when I had to change the clutch cable, and it was a 3 day job. The Cobra is my only transportation right now, so I can't afford to be without a car for 3 days....maybe a weekend, but the local welding shop is closed on weekends, so there I am back at being without a car on a workday....[sigh]!

Thanks, Bob and all, for all your help. Right now I think I may just replace the MC with a similar 1" bore model...and approach a wholesale change of the pedal mechanism when I have more time and $$  .

Cheers!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

Last edited by YerDugliness; 09-26-2012 at 07:08 PM..

Reason: spelling...it's ALWAYS spelling for some reason :-(

|

09-26-2012, 07:49 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

you can pull back that rubber over the brake rod and measure the master cylinder bore--since its leaking and needs replacing, buy one that is 1/8 smaller bore which will increase your line pressure----

I see that you have speed bleeder screws in your wheel cylinders, thats a gonna make bleeding your brakes a one man job!!!!!!!!

Last edited by Jerry Clayton; 09-26-2012 at 07:53 PM..

|

09-26-2012, 08:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Dugly,

Ok, hmmmmm.... I have just gone through a full brake system inspection, redesign, and implementation. I was able to gain the results I was looking for with a lot of help from some people on CC, and the Internet.

First of all Pedal ratio

The statement that a larger pedal ratio for manual brakes is true, however what I have found is that manual brake pedal ratio actually starts at 5:1 ratio. Yes, it is true the small the pedal ratio the more pressure will need to be applied to stop the vehicle, compared to a larger pedal ratio. As mention in this thread a 6:1 ratio is ideal. In any spread sheet I have seen to determine the master cylinder size the applied pressure rating is always to determine lockup pressure of the tires. So keep in mind if you really want to lockup the tires you have to be realistic with the pressure. I would recommend about 150 lbs + / -.

You MUST determine that the push rod travels completely straight with a + / - 2 degree variance. Indication of the leaking on the firewall maybe a sign that the push rod is not traveling with full stroke completely straight.

Calipers

In order to make a educated suggestion, we will need to know caliper piston size of the calipers. By indicating that the calipers for front and rear are the same may not be true. A lot of Wilwood calipers can be ordered with different piston configuration. As an example the same calipers can carry a 1.75 piston or a 1.38 piston in the same physical bodied unit.

Furthermore, these calipers vary for rotor size thickness which will help in heat dissipation. The further you can put your caliper away from the center or the rotor the easier it will be to slow down the rotating mass, due to it spinning slower.

Line Pressure

Recommend brake lines should be 3/16 and hard lines should be used where ever they can be used. Areas that require movement such as body to chassis or chassis to caliper should have a good quality braided brake hose.

Wilwood calipers are rated at 1200 psi before deflection occurs. Manual brake pressure are typically around 600 - 1000 psi. SSBC suggests brake pressures to be between 600 - 800 psi, I think anything lower than 600 psi for the front and dont even drive the car.

You can find these pressure gauges in the popular online shops. I would recommend getting 2 to 3 gauges. 1 for the front 1 for the rear and the 3rd (optional) for the master cylinder. The 3rd pressure gauge will help show the variance from the mc change to the calipers. Don’t confuse this pressure with clamping force, which is much greater.

Dual Master Cylinders VS Tandem

By going with a dual MC you will be able to configure / tailor your brake system to you liking easier. This is mainly because you have a larger variety or cylinders to choose from and mix and matching front to rear selections. Keep in mind the amount of pressure being applied to the dual setup is divided in ˝. So, if a dual system receives a applied pressure of 150 lbs. this pressure is divide amongs 2 cylinders delivering 75 lbs each. A balance bar will help distribute this applied pressure (150 lbs) evenly or unevenly to either your front or rear. A proportioning valve is installed on the rear reducing the pressure to the rear braking system.

A tandem system will receive a full amount of pressure applied through a single push rod. Keep in mind this system is less tunable with the limited sizes that can be applied.

In conclusion, you will find many examples of dual MC’s with a selected value but good luck finding all the variations in a braking system for you to create a cookie cutter system to apply to your situation. My suggestions and to save time and money would be to make sure you do your homework on this. You do not want to take the cheap route with your brakes. I have adapted a Wilwood pedal system (hanging mount) 6.25:1 to my application. I initially thought the system would not fit in my foot box but until I fit and tested the system it worked very, very well. Additionally, keep in mind by increasing you clamping force in the rear this in turn reduces the amount of effort needed (to a certain extent) to the front. Typical balance for front to rear is a 70 /30 (front /rear).

The knowledge I have obtain and suggest in thread is what I have gathered, tested with working results on my own vehicle.

This is just a small percentage of information that I have gathered and share, a lot more information is definitely needed. I hope this help you and others, braking should be taken seriously.

|

09-27-2012, 06:12 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2000

Location: St. Augustine,

FL

Cobra Make, Engine: E-M / Power Performance / 521 stroker / Holley HP EFI

Posts: 1,944

|

|

Not Ranked

Not Ranked

Dugly,

Wow!

Looks like the components are there in your photographs, but in dire need of attention.

For example, the fluid in the master cylinder seems to be more mud than fluid. Also, the front rotor you have pictured seems to be lightly used, if at all. It looks as if the caliper is hardly clamping on it...

My suggestion is to start by rebuilding or even better, replacing the master cylinder and calipers. The pads look OK. And while you're at it, flush the lines thoroughly. If you're uncomfortable doing this, get a mechanic who knows brakes and let him do the overhaul.

After the rebuild would be a good time to revisit the braking power problem, since what is pictured can't be operating efficiently. A good rebuild should increase the stopping power of your car by a lot.

Just my 2 cents!

Tom

__________________

Wells's law of engine size: If it matters what gear you're in, the engine's too small!

|

09-27-2012, 06:40 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

Thanks, Tom....about the fluid....I was unaware it was leaking out, and not long ago I noticed a slight deterioration in brake function so I pulled the cap and found the large reservoir completely dry. I filled it, then realized through more frequent checking that it was leaking out somewhere, so I got a turkey baster and emptied the old fluid, wiped out the sediment from the reservoir, and put in new brake fluid. It gets cloudy like that pretty quickly....I don't think it is humidity, I think it is rust from the inside of the reservoir that is staining it. I did empty the smaller reservoir once but have not paid the attention to it that I do to the larger reservoir. I suspect that a flush of the system will reveal that there is significant air in the lines...and, if as I suspect, the larger reservoir supplies the front brakes, that might be the reason that the rotor looks the way it does. I can lock up the front brakes, in fact do so frequently as I am backing out of the garage as the driveway slopes down at a good angle and the weight is transferred to the back wheels.

I am pretty comfortable with brake work, have done my own on my Fords and Hondas for years, just don't understand the theories behind the mechanicals. I hope to reach Wilwood today with the numbers I got off the calipers and find out about rebuild kits...supposedly the rebuild involves a new O-ring on the pistons and little more, we'll see. I agree that the front brakes might not be working at maximum efficiency, the verbal history on the car indicates it was built in 1994 and these would be the brakes used in the build as there is slightly over 8K miles on the odometer. Almost twenty years since it has been built....and no brake work since then....sounds like it is time! I can replace the MC and rebuild the calipers in a weekend, that's doable

For now the MC will get replaced, the calipers rebuilt, and the system flushed, but once the car is up on jackstands for the winter, a totally different braking system might well be in its future, a dual cylinder one like Bob C pictured in his first reply.

Thanks to Tommy for spending time with me on the phone last night, I now understand better the impact of changing the bore size of the MC....will replace the MC with a similar size bore (or, pehaps, smaller as recommended by Jerry) rather than increasing the bore size. Sometimes things involved with hydraulic theory seem counter-intuitive!

Cheers!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

Last edited by YerDugliness; 09-27-2012 at 06:47 AM..

Reason: content

|

09-27-2012, 06:46 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: No city...only 118 residents in Manter,

KS

Cobra Make, Engine: Cobra Auto Works body, Ron Godell Racecars chassis, 1989 Mustang GT 5.0 HO (converted to carb), W/C T-5, 3.73's in a Ford 9" Traction-Loc.

Posts: 812

|

|

Not Ranked

Not Ranked

I need to find out more about this!

I need to find out more about this!

Quote:

Originally Posted by Jerry Clayton

I see that you have speed bleeder screws in your wheel cylinders, thats a gonna make bleeding your brakes a one man job!!!!!!!!

|

This is something that I am not familiar with....I will discuss the issue when I am on the phone with Wilwood's tech department today. I like the idea of being able to do it by myself....do the "speed bleeder screws" function as an anti-reverse valve, allowing one person to pump the brakes and fill the MC with fluid without the need for a second person working at the calipers, opening and closing the bleed valves? That would seem reasonable....just wondering if anyone can illuminate me on this.

Thanks for all the help, fellas....I have really learned a LOT in this thread!

Cheers to all!

Dugly

__________________

YD,E./PNB

No names were changed to protect the innocent!

|

09-27-2012, 08:44 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2000

Location: St. Augustine,

FL

Cobra Make, Engine: E-M / Power Performance / 521 stroker / Holley HP EFI

Posts: 1,944

|

|

Not Ranked

Not Ranked

Dugly,

While you are rebuilding, don't forget the hard lines and especially the flex hoses in the brake system. There are at least three flex hoses: one to each front caliper and if you have a live axle, there will be one somewhere around the center of the axle where the driveshaft hooks in. If you have IRS, the flex hose locations will be similar to the front. Unless you have a Jag rear, which is all hard lines at the rear... Anyway, you get the idea. The -3AN flex lines in the pictures might still be good to reuse.

Be sure to inspect the hard lines for any cracks or fitting leaks.

I think you are on the right track.

Tom

__________________

Wells's law of engine size: If it matters what gear you're in, the engine's too small!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 03:19 PM.

|

2Likes

2Likes

that I don't understand this, I'm usually very competent regarding mechanical issues and this one is evading understanding.

that I don't understand this, I'm usually very competent regarding mechanical issues and this one is evading understanding.

.

.

Linear Mode

Linear Mode