I have been working on an engine build the past year and I thought I would share with U guys.

The goal was to build a one off, very potent, yet somewhat exotic naturally aspirated small block that would produce substantial amount of HP, and TQ, run on 93 Octane, and have acceptable manners for the street use (A tall order in deed).

I begin an inventory of what I had and what I needed to complete the goal. I enlisted help of Jim Kuntz of Kuntz & Company to help me develop my goal. For those of u who are not familiar with Jim kuntz, let me introduce you. Kuntz and Company is an upper tier level engine builder who specializes in Ford engines. Jim is old school. He does not advertise and his web page is not much to look at, but his customers hold more records then I can list.

I called Jim and told him I wanted 700+ HP, 600+TQ pump gas small block, and I did not want to break the bank. He laughed and said “you and everybody else”. We discussed different combinations for about an hour before a plan came together. We decided that most of my current short block components (463 SBF) were up for task, but the heads and cam had to go (I had already decide on a stack Injection)

My original engine consisted of a Dart sportsman block, Eagle 4.250 crank, Eagle 6.3 H beam rods, Race Tech Pistons .875 Crower sever duty solid roller lifters, LSM solid roller cam, AFR 225 heads, Edlebrock super victor intake, and a Quick Fuel 850.

The short block was disassembled and parts inspected and machined if needed. The block was prepped for race use, extra attention was given to oiling and machining and cleaning up the block casting. The forward lifters bores were plumbed for improved oiling. Center drain holes in the lifter galleys were blocked off, and the front and rear drain holes were enlarged. Lifter bores were enlarged and bronze bushings installed. New ARP 2000 rod bolts were installed along with a new set of Crower EnduraMax .903 bushing lifters. The Race Tech Pistons received a set of Total Seal Rings, Avaid supplied the S2 5 stage dry sump pump, Armando supplied the

oil pan, and a Patterson tank holds the

oil.

Kuntz is a master with induction flow and a lot of time was spent discussing different head and cam choices. I eventually decided on a set of TFS (TEA) 240cc Hi Ports (no problem finding shaft rockers or pistons). The heads were designed for 427+ CI engines, and target mid lift flow. Valves provided by Ferrea (5/16 Steams),and Springs are PAC circle track 1500 series. Crower stainless shaft rockers (1.70 Ratio) with pin oilers keep everything stable.

Flow figures provided by TEA (2” pipe) are as follows:

Lift Intake Exhaust

.300 233 168

.400 292 209

.500 322 238

.550 331 250

.600 342 258

.700 350 269

LSM supplied the custom ground camshaft. 110 LSA 270/279 duration, 696 /690 Net lift (installed at 105.5) . I discussed the spread on the duration with Jim and we both agreed with the extra long primary tubes that are indigenous to cobras, that more exhaust duration was needed. Ramps are not overly agressive since primary duty is street use.

Sitting on top of the TFS (TEA) heads is a 3 piece Hilborn IR injection system. I chose the Hilborn over other brands because of the larger runners (2 7/16 blades) available for the 351W based engine. I talked to many of the other manufactures before choosing Hilborn. When pressed, most other manufactures admitted that their product would not make the horsepower I demanded. Kinsler and Engler Machine were at top of my list, but Kinsler was above my price point and Engler did not make Aluminum Runners (magnesium only).

Injectors are from Injector Dynamics.

Ram tubes provided by Engler machine (Tim Engler can make any Ram Tube dimension you might need).

Accell DFI dual sync distributor fires the plugs, and receives its timing commands from a Fast XFI 2.0 ECU. Headers are custom stainless steel steep headers 1 7/8 to 2” with SPD 3.5 collectors (My headers were used during the dyno session).

Dyno day finally came, but not without problems. The center cylinder’s (2,4,6,7) would pulse and spark, but the outside cylinders would not. The computer was showing the rpms during cranking ranging from 0 to 12000! After retracing wires, rechecking grounds, ½ the problem was found (cam and crank signals reversed in DFI harness from the factory). I reversed the pins, but the cam signal was still not working correctly so we switched to bank to bank. It had taken all day to resolve the problems. Time was running out. It was now 5PM and we had not started the engine. Moment of truth “Fuel pump on and a push of the start switch”. The engine fired off and idled at 750RPM. Idle was adjusted to 1100 and couple small leaks (loose AN fittings)fixed, and some quick timing adjustments and we are off to the races. Break in was uneventful and no metal found in the

oil filter.

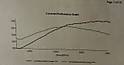

First pull would be from 3500 to 6500. Some adjustments were made to air fuel ratio, timing, and another pull to 6500. Still running lean in 4000 to 5500 range so more adjustments made and another couple of pulls to 6500. Timing was set to 32 degrees. Next pull was to 7000 and dyno read 741HP at 6600 and TQ 633 at 5400! Timing was adjusted to 34 degrees and another pull to 7000. The engine liked the extra timing, yielding an Averaged hp of 581 and 574 TQ. Max HP was 738 and max TQ 648. Out of time and well pleased with the results we called it a day. I discovered after I got home that we had forgotten to adjust the timing above 6500 prior to our 7000 rpm pulls. With more time I am sure we could have squeaked out 750HP.

Important Notes:

Engine was dynoed with following: Alternator, engine driven water pump (overdriven), Cobra headers, 93 octane, Break in oil, Vacuum relief set at 10”

Compression 11:1

My headers were used during the dyno session

Precision Race Engines preformed engine dynoing.

Special Thanks

Jim Kuntz Kuntz & Company

Mark Davis Precision Race Engines

Mike Schmidt Total Engine Airflow

Steve Sr. LSM

Rich FastmanXFI

Andy Hilborn Fuel Injection

Tim Engler Engler Machine

Mike Patterson Patterson Enterprizes