It's not the vapors that are the issue, it's crank case pressurization that you are trying to avoid.

Your engine is a pump with it's pistons going up and down. There is air being displaced from one cylinder to another inside the crank case. Your combustion pressure on the top of the piston is held in there by the seal of your valves and the seal of the rings. Your piston rings are designed with a taper in the back that lets the combustion pressure help push them out against the cylinder walls for a better seal.

That seal is never perfect so some of that combustion pressure leaks past and into the crank case. This is commonly know as blow by. It's not a problem but needs to be managed. If that leaked pressure from your combustion cant get out of the crank case you will build up positive pressure and start pushing the

oil out of every gap it can find. The other bad thing crank case pressure does is act against that combustion pressure doing it's job pushing the rings against the cylinder walls for a better seal.

The PCV (Positive Crankcase Ventilation) valve was invented to combat that. By using engine vacuum any excess crank case pressure is drawn off into the intake. Ideally it will run with some negative pressure in the crank case helping the ring seal. It was also an early emissions device as it draws off any

oil vapor and combustion gasses to be burned in the motor rather than venting to atmosphere.

The downside of this is that depending on how efficient the

oil separator is you could be burning oil vapor in your combustion chamber which lowers the effective octane rating of the fuel.

I prefer venting to atmosphere but the important thing here is flow. There is no engine vacuum to help draw off that pressure so breathers or hoses to breather tanks /catch cans need to be be a good size.

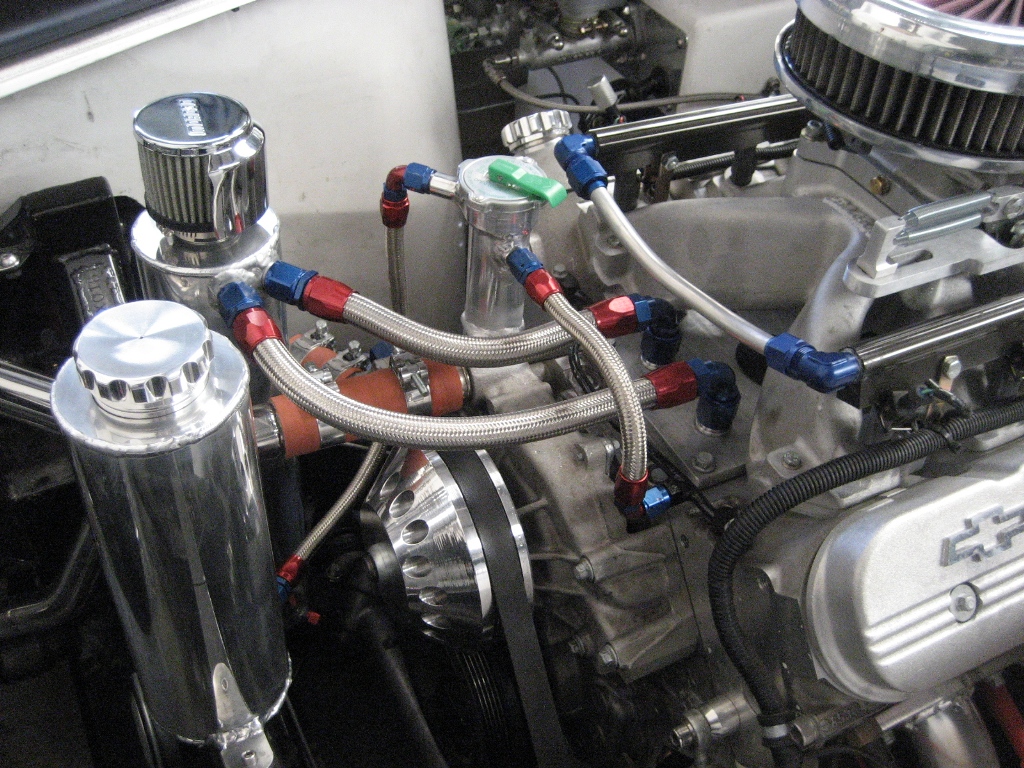

My setup currently has a large catch can oil separator that is baffled internally. This is vented to atmosphere by a filter breather. The can is connected to the crank case via the valley plate via 2x AN#10. I chose the valley rather than the rocker covers as I figured there may be less oil vapor washing around in there than the valve covers. The bottom of the tank has another fitting with a 1 way check valve to allow collected oil to drain back to the sump on it's own.

Not saying it's ideal but it's the way I thought I'd try.

Cheers