There seems to be a different opinion of what a Proportion Valve does in the brake system.

I've worked with Mac Tilton back in the 70's and 80's and let me explain what a Proportion Valve is suppose to do. Remember Back in those days, we didn't have the Adjustable Balance Bar on the Brake Pedal back then. We needed to reduce the pressure on the rear brakes to prevent them from locking up when we got on them real hard. I'm only going to talk to the Proportion Valve many of you use on your existing Cobras since most of them are hand built and people just don't understand what they are doing when installing a Proportion Valve.

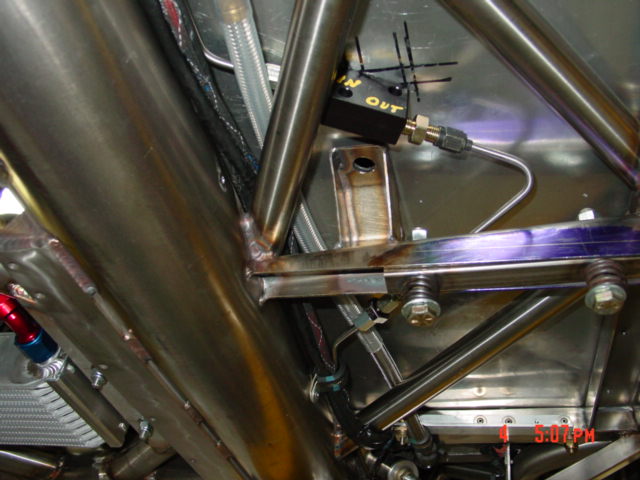

This is the Knob of a Tilton Proportion Valve

Think of a Round Housing with a Ball Bearing and Spring inside the housing, then cap the other end of the housing and put a screw with a knob on it so that when you screw the knob in.... it compresses the spring to the point that the ball bearing plugs the orifice that is coming into the bottom of the housing. So if you run Brake fluid into the housing under the orifice it can go out the other in of the Tee Housing or up into the Orifice and push against the Ball and Spring. Turning the knob will make the spring compress against the Orifice and move it up or down in the housing, if you back the spring out, and you apply the brake pedal, the fluid will go to the brake calipers and then based on where the Proportion valve is set the pressure will back up into the orifice and the spring will give and lower the pressure applied to the calipers. If you screw the Proportion Valve all the way down .... when you step on the Brake Pedal ... the brake fluid will go to the caliper and then the spring will not give, so you will get all of the pressure the rear master cylinder is putting out to the Caliper.

So the proportion valve is just a valve with a spring and ball bearing in it and based on its spring pressure is how much rear brake you are going to get before it releases the pressure into the spring loaded proportion valve. Wewww...

As you can see in this photo.... there is only a input and output to the Proportion Valve.

So let's say you have your foot on the brake pedal and are pushing hard and you have gauges on the front calipers and the rear calipers. With the Tilton Proportion Valve screwed all the way in .... the Gauges will read 1000#lbs on the front and 1000#lbs on the rear.

Now same situation but you unscrew the Tilton Proportion Valve half way ... the reading on the gauges will read 1000#lbs on the front, but the rear will read 500#lbs on the rear because the spring in the proportion valve will retract the amount you have unscrewed the Valve so that as the caliper starts to clamp on the Rotor, it can't clamp with as much force because the spring is moving not letting the caliper get all of the pressure coming from the master cylinder.

So now you need to have the valve close to you so you can adjust the rear bias of the brakes while running the the vehicle....

There are many way to see what is going on with you brake bias.... That's a hole additional subject. That we'll get into later.

I hope this helps out the guy's that have a single Master Cylinder.... understand what is going on with their proportion valve.

Morris