Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

44Likes 44Likes

12-11-2020, 11:15 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

+1 on everything Rick just said Hauss.

If you still have any of the broken shafts could you post a picture of the pieces. I am interested in what the broken parts look like. If possible a reasonably close picture of the fracture surface would be nice.

Thanks.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

12-11-2020, 04:29 PM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

pictures

pictures

I am not the best at sending pics. I will say I do believe the pin is over hardened causing it to crack.

|

12-11-2020, 04:35 PM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

Found the problem I have another post labeled TKO 600 with pictures already.

|

12-11-2020, 08:32 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

There are a number of high strength steels like 4330 /4340 / 8620 /9310 that you can use. Probably any will work. Get it centerless ground and cut the o-ring groove and you should be done. I took a quick look at one of the online metals suppliers and a centerless ground 36 inch long ¾" diameter bar of W1 tool steel costs about $24.

I don't know the length of the Tremec shaft but lets say 6 inches. That means the raw material for 6 shafts would come to about $4 per shaft. Cut an o-ring groove on one end, send it out for heat treat and you would probably be around $10 or $15 cost per replacement shaft. If you wanted you could get exotic with 9310 or 4330 and have a super piece.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 12-12-2020 at 01:56 AM..

Reason: Spelling & Grammar

|

12-11-2020, 09:16 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Here is some more info on the 2-3 shift issue.

Note the OP also broke his 5th/rev rail from too many missed 2-3 shifts:

https://www.camaros.net/threads/trem...roblem.345361/

__________________

Gary

Gold Certified Holden Technician

|

12-12-2020, 04:24 PM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

You forgot the man doing the work part. If I could drum up some interest who among you will shell out $100.00 per rail. If I can get 10 of you then I will proceed.

|

12-12-2020, 09:28 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

I think the challenge you are going to run into here, Hauss, is that the average guy can buy the steel cheap, machine a snap ring groove on his buddies lathe, buy the snap ring for less than a dollar at McMaster and get the shaft heat treated, with some luck and talking for way less than the $100 target you are looking at.

That makes it a bad business proposition for a for profit business because as you said the guy doing the work was left out / forgot. Just some of the sad economics associated with this type of business ...

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 12-13-2020 at 09:38 AM..

Reason: Spelling & Grammar

|

12-12-2020, 09:44 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Here is a video:

https://www.youtube.com/watch?v=8YBeFZzv83Y&t=1815s

At 20:21 is where Paul is removing the 5th/rev shaft.

__________________

Gary

Gold Certified Holden Technician

|

12-13-2020, 09:50 AM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

Yep that is the rail, minis all the work it took to get to that point, also let us not forget we still have to get it back in the car.I have done this procedure 3 times already, in 8k miles. Mr. Esschaider; anyone who has done this one time would gladly spend $200 dollars for a rail that worked. I certainly know I would.I am a retired guy with more time than money and still I would. the $100 would only go to the first 10 people.

|

12-13-2020, 10:22 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

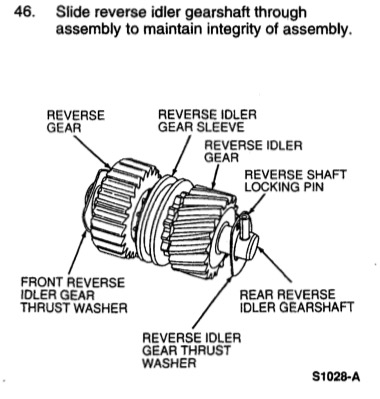

Thanks, Gary. As we watch Paul's assembly of the reverse idler shaft something jumped out at me. Tremec machines a relief in the main case for the dowel pin that is used to limit the forward movement of the shaft. The relief is adequate to allow the tailshaft to be assembled to the main case without interference with the dowel.

If the reverse idler shaft is modified to use a snap ring the case will need to be machined to provide a relief for the snapring to register in so it does not prevent the tail shaft from fully seating against the rear face of the main case. In actual fact you would probable want to machine the main case to accept a hardened washer that would fit between the snap ring and the main case.

The reason I an suggesting the washer is that a snap ring only has a small shoulder that would stand proud of the reverse idler shaft. We already have a shaft that is being forced forward with enough force to break the end of the idler shaft. With just a snap ring and no larger diameter washer to spread the force over, I suspect the snap ring would be mushed into the aluminum backside of the main case.

That means a second machining operation, this time on the main case, to accommodate a thrust washer. Not impossible to do but the mod has just taken a significant step up in complexity and potential transmission main case damage if not done correctly.

Discretion may be the better part of valor here. My car has 295 tires in the back and at 7000 rpm in fourth gear is a whisker north of 191 mph! I (fortunately) lack the poor judgement to tempt disaster by running it that high in fourth before shifting into fifth, In the real world it would appear that if you could not beat the car next to you before the end of second gear let alone fourth gear, (assuming you have not crashed yet) a power shift into fifth gear is not going to improve the situation .

This particular component failure begs the question why are we power shifting into over drive at lower speeds where fourth gear is the better gear to be in. Even with the stock 3.46 ring and pinion my car was delivered with, 4th gear is good to well over 160 mph! Frankly at anything significantly over 100 mph or so in these cars require a steely spine and stunningly good driving skills not to mention a good dose of bad judgement.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

12-13-2020, 10:31 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by hauss

Yep that is the rail, minis all the work it took to get to that point, also let us not forget we still have to get it back in the car.I have done this procedure 3 times already, in 8k miles. Mr. Esschaider; anyone who has done this one time would gladly spend $200 dollars for a rail that worked. I certainly know I would.I am a retired guy with more time than money and still I would. the $100 would only go to the first 10 people.

|

Hauss, in as much as you have already done the market research, determined market size and buyer willingness to purchase at a particular price point, it appears all that is left to take advantage of this excellent business opportunity is for you to contract for the manufacture of these replacement parts and profit handsomely from the sales. I think you should do this sooner rather than later. This could change your personal situation into one of a retired guy now with more money than time.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

12-13-2020, 04:46 PM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

Sounds good Ed. Shall I put you down as the first in line?Oops 2nd,Ill be the first only 8 more to go!

|

12-13-2020, 04:51 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Ed,

I think you are confusing 2 shafts.

One is the reverse idler shaft, which is a captive shaft for the reverse idler to spin on. The other is the 5th/Rev rail, which is the the rail that has broken in Hauss's case.

I do find it hard to believe how that rail breaks, and yet the roller pin small diameter should fracture first.

__________________

Gary

Gold Certified Holden Technician

|

12-13-2020, 04:53 PM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

FyI. you cannot buy the rails from hanlon or silversport they are all sold out. Not sure what to think.Found one on ebay $50 shipped to my house.

|

12-13-2020, 04:56 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gaz64

Ed,

I think you are confusing 2 shafts.

|

Yep, the original from 1971 was the best. You know, the first one with Richard Roundtree.  |

12-13-2020, 07:37 PM

|

|

CC Member

|

|

|

Join Date: Dec 2019

Location: Long Island,

NY

Cobra Make, Engine:

Posts: 205

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by spdbrake

|

Some of the FAQ on that page says that the TKX is longer than the T-5 and therefore requires a new driveshaft.

__________________

Adam

Fulfilling my lifelong dream to own a Cobra... MISSION ACCOMPLISHED!

MKIV FFR 347 cid, Levy T5, 3.55 3-link.

SOLD  Replaced by something with a Flat-6

|

12-13-2020, 07:57 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: SF, Bay Area,

CA

Cobra Make, Engine: SPF832, 466cid

Posts: 511

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Yep, the original from 1971 was the best. You know, the first one with Richard Roundtree.  |

He's a bad mother.....shut yo mouth! |

12-13-2020, 11:17 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by hauss

Sounds good Ed. Shall I put you down as the first in line?Oops 2nd,Ill be the first only 8 more to go!

|

Actually I don't power shift fifth gear at any speed, let alone low speed and significantly have never broken even one reverse idle shaft sooo, I'm probably not a prime candidate for a replacement piece.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 12-14-2020 at 09:23 AM..

Reason: Spelling & Grammar

|

12-14-2020, 12:06 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gaz64

Ed,

I think you are confusing 2 shafts.

One is the reverse idler shaft, which is a captive shaft for the reverse idler to spin on. The other is the 5th/Rev rail, which is the the rail that has broken in Hauss's case.

I do find it hard to believe how that rail breaks, and yet the roller pin small diameter should fracture first.

|

You are correct about the two being different parts, Gary but I thought Hauss was describing the reverse idler shaft in his post #102 when he showed this pic of a new and a broken shaft;

The identifier I was using was the roll pin hole in the end of the shaft. It appeared that the shaft was the shaft pictured in Paul's video at time = 35:43 and in the Tremec manual in the image below;

Actually I am relatively agnostic with respect to naming conventions other than for identification purposes as long as they are somewhat representative.

Edit out: The reverse idler shaft apparently experiences an in service forward thrust, which Tremec attempts to blunt as can be seen by the presence of the reverse idler gear thrust washer in the Tremec service manual illustration. The direction of the thrust, if it were great enough, could certainly break the back side of the roll pin hole off the end of the shaft as Hauss has illustrated in his picture in post #102.

Looking at the assembled component I must admit I am struggling with trying to understand where the forward thrust that fractures the end of that shaft is originating from. That said, it is apparent from their use of a thrust washer and Hauss's success in repeatedly breaking the part that the thrust is real and does come from somewhere.>

Edit in: That thrust washer goes inside the main case not outside, which makes more sense. The helix on the gear would push the gear rearward not forward and a thrust washer inside the case would protect the case from the rearward thrust on the gear. That really leaves me at a loss to explain the failure.

The fact remains however, that fourth gear tops out even with a 3.46 (or thereabouts) rear gear set at nearly 200 mph (with 295 tires) which still begs the question, why are we power shifting into fifth gear overdrive down in the second or third gear vehicle speed range? That sort of operation does not seem to either be a smart or a competitive way to drive the car — and could likely be a contributing factor to the repeated component failures Hauss's transmission is experiencing.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 12-14-2020 at 02:34 AM..

Reason: Added Edited commentary

|

12-14-2020, 03:35 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

The photo above of Hauss's broken 5th/rev rail shows 2 pieces at the fracture point. The roll pin secures the roller that follows the selector lever.

About 20:20 in the video.

Gary

__________________

Gary

Gold Certified Holden Technician

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:33 AM.

Links monetized by VigLink

|