Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

01-12-2009, 01:01 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

Can someone explain why the "Tuner" lug nuts wont work.

Secondly why we can not machine the hub adaptors to the same angle as the pins as Rick mention in the begining of this post.

|

I would have to measure the tuner lugs to make sure what I am about to say is right.

My inclination is they are not made to be concentric--they don't need to be. The axis of the threads may not line up with the axis of the OD of the pins. Tuner lugs are not driving the wheel on the OD of the pin.

The taper of the tuner pin may not match what the taper in the hub adapters is--90 degree in Trigo and 60 degree in Vintage. From the post you can see I measured Trigo pins in the rather strange 76 degree area--not standard from anything we are used to here.

Tuner pins do not hold the OD to any specific tolerance--it can vary widely leading to stuck pins in the wheel holes.

Hope this helps. I am happy to try again if need be.

David

|

01-12-2009, 05:16 PM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Corona del Mar,

CA

Cobra Make, Engine: FFR MKIII, FMS BOSS 302 "B" cam

Posts: 170

|

|

Not Ranked

Not Ranked

Any update today David?

|

01-12-2009, 06:18 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

I have some photos that I took earlier today, but I just can't break free to post them. For some reason, we are selling parts like crazy right now.

I will try to post them soon.

David

|

01-12-2009, 08:03 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

WOW! What a day. Lots of parts to ship.

Anyone who is following the thread knows the Trigo pins I measured were at 76 degrees. I assumed (very BAD thing to do) they were a standard 82 degree taper and so we made about 100 of them at 82 degrees. When things started to not look right, I busted out the angle gauge and found I was a dummy...and so was someone else. The tapers on the pins were 76 degrees??? WTH (For you non-Utah people, that means "What the Heck."  We later found out the Trigo hub adapters have a 90 degree countersink in them. Someone had a little too much weed when they were making thos pins.

So, we had a bunch of bum parts. Concentricity, is critical in this part (along with most parts) so we specially machined the jaws on the lathe to fit a collet chuck. We then chucked the pins up in the collet chuck to make sure they were absolutely straight, and we corrected the taper to 90 degrees. Bummer to machine the parts when they are already hard, but carbide doesn't really care too much. You just have to go a bit slower.

Last edited by David Kirkham; 01-12-2009 at 08:08 PM..

|

01-12-2009, 08:10 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

You see, what most people (who don't machine) don't realize, is how easy it is to chuck a part up in the lathe and not get it in straight! Happens ALL the time. A collet chuck really helps to bring that concentricity back to 0.

I HATE crappy parts.

David

|

01-12-2009, 08:20 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

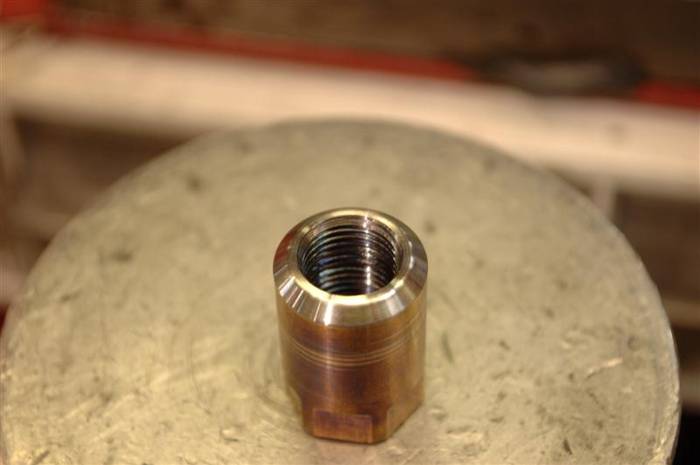

Notice how we cut the tapered end (the pointed end of this part) right off. Compare to CNGreen's part above with the crack in it

The original Trigo part as a very sharp area where the thread starts (the taper area). The problem is, as that area gets thinner and thinner the steel obviously gets weaker and weaker. Cutting the thread into the part only exacerbates (I learned that word from Jamo  ) the problem. Then you torque the boogers out of that thin little starting thread and BAD things start to happen. That first thread will "pull" out and raise up. It will raise up where it is the weakest--right at the end of the thread. That weak area will raise up (remember, only on one side now--right at the beginning of the thread as it only starts in ONE area) and it will cause the pin to tip!

Sounding familiar???

So, we trimmed the point off (remember CNGreen's crack in the taper) and then deeply deburred the thread so it could not pull. This becomes a very important object lesson. Many times you can REMOVE material from a part and make the part a STRONGER part. Here is a perfect example.

Now you know why our parts cost so much. We try to think about everything. Thinking takes time; deburring takes time, programming takes time, finding the right alloy takes time; you get the point. You can purchase cheap parts...but sometimes (well, usually) it will come back to bite you on the bum bum.

Notice the large nose radius on the taper.

Last edited by David Kirkham; 01-12-2009 at 09:29 PM..

|

01-12-2009, 08:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a final pic of the finished part. The cool bronze color is from the precipitation hardening. Notice the color was lathed off when we corrected the taper to 90 degrees.

OK, they are now officially for sale. All takers, please contact me!

kirkhammotorsports at gmail dot com

REMEMBER!!!

These are 90 degree tapers!!!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:15 AM.

Links monetized by VigLink

|