Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2025

November 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

07-21-2007, 06:33 PM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

Jag front suspension / steering geometries

Jag front suspension / steering geometries

Having taken the beast down the court and knowing my front end was not set worth a pinch, it was mildly frightening to then try to steer and find the front end just skate.

Clearly need to set the front end up properly now but am chasing advice on what settings might be worth a first try.

I have no exposure to setting up suspension but provided I have some target numbers I'll find my way there with a little help from my friends!!

Camber, castor, toe in for a series 2/3 Jag for these cars - what is suggested please?

I know ride height will play an intial part in the settings and I want the front tyre clearance to the bodywork to look sensible and am not chasing any super low settings. Just a stock looking arrangement is the best way for me to describe it.

Is there any suggested spacing in this regard too?

Any comments would be appreciated, so that my next foray  might provide me with a greater confidence level as to whether the car will go around any corners I encounter.

Cheers

__________________

slowy

|

-

Advertising

07-21-2007, 07:34 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Check with G-force.

Depends where they set up the a-arms etc.

RMC recommend a start point:

Front camber: 1/4 to 3/4 degree positive

Front caster 3 degrees

Front toe 1/16" to 1/8"

Rear Camber 1/4 to 3/4 degree positive

Rear toe: Zero.

Don't overspring the car.ie, make sure you have suspension movement.

Cheers

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

07-21-2007, 07:57 PM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

I use 1.5 Degrees neg camber on all four wheels about 3 degrees castor on the front and 1/8 toe on all four wheels .Anti sway bar front and back.

|

07-22-2007, 04:31 AM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: Melbourne Australia,

VIC

Cobra Make, Engine: 1991 RMC 1966 427SC replica, 302 Cleveland, Edelbrock manifold with 600 Holley double pumper.

Posts: 154

|

|

Not Ranked

Not Ranked

Alignment & Specs

Alignment & Specs

Stephen,

One thing you should do first is make sure your rear end is square on the car as you will need to do a four wheel alignment when ready. It is easier to make small adjustments if you rear end is set well before you do the front. Do you have adjustment on your trailing arms on the rear? You will have a little bit of movement in the bushes but not much. I found aligning the rear the most difficult as my fuel tank makes it difficult to add shims to make the major adjustments. I was lucky I had enough movement to get the rear pretty square.

My RMC is running 3° Caster, 1° Camber on front and about 1/8" toe. My rear is running about 1/2° - 3/4° Camber and almost zero toe. The Caster change to my car made a huge difference to track and fixed a majority of steering issues I had when I bought the car.

Cheers

TC

|

07-22-2007, 05:08 AM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Stephen, regarding the set up of the rear end as mentioned by Tony. Tony is certainly correct about getting the diff square which is an almost impossible task with the RMC unless you modify the top mounting plate. I know you have a G-Force but they are closely related.

With regard to the toe of the rear end and the difficulties to change it by way of the shims under the inner pivot bracket.

OzVenom has a modification he makes to the lower arms and the alloy hub which allows for the toe to be changed very easily at the hub end of the arm without having to get to the diff center. I'm not talking about stressing the trailing arms as they should be firm but not tight. Keep in mind the trailing arm moves thru an arc therefore overtightening to increase toe and or squarness is not recommended.

You would have to send Scott your lower arms and alloy hubs but it is a modification that certainly makes that job painless.

Cheers

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

Last edited by Rebel1; 07-22-2007 at 05:26 AM..

|

07-22-2007, 05:46 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: Melbourne,

VIC

Cobra Make, Engine: RMC, carb 347 TopLoader and Jag running gear ~ so old school I time it with an hour-glass :D

Posts: 1,293

|

|

Not Ranked

Not Ranked

While we're talking Jag Suspension - does anyone know of a supplier of adjustable upper arms to replace the std. Jag so that you can wind them in for a track day then out again for more social driving?

Also Stephen - When I was first setting the car up I just measured the distance between the front of the front tyres and the back of the front tyres to get the alignment in the ball park - giving it a little toe in.

Not very sophisticated and maybe I was just lucky but it made a big difference

(Make sure you measure at the same height from the ground or any differences might not be apparent or may be exaggerated)

LoBelly

|

07-22-2007, 05:52 AM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Wished I did know LoBelly. Would be much easier than removing all those camber spacers.

Cheers

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

07-22-2007, 06:23 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Paradise Point,

Qld

Cobra Make, Engine: Absolute Pace

Posts: 1,205

|

|

Not Ranked

Not Ranked

Been There done that

Been There done that

I have had set made up, they use the bolt in lower jag ball joint.

I have made new mountings drilled and tapped rather than the shafts. The mount in welded to the chassis as this arangement allows for a simpler adjustment of caster and chamber.

That is what I was thinking of doing, set up for the track then undo the bolts wind out 2 turns then it is right for the street.

Phil |

07-22-2007, 06:27 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Mildura,

vic

Cobra Make, Engine: FFR Coupe, 416ci of LS goodness

Posts: 2,349

|

|

Not Ranked

Not Ranked

I like them a little too much..

MUST RESIST URGE TO PULL FRONT END APART AGAIN!!

__________________

Powered by Cu

|

07-22-2007, 10:10 AM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

I would also put a plate under the lower control arm (ie brace it ) where the original spring mounts go,From the bottom.It helps to reinforce the lower control arm.

|

07-22-2007, 05:04 PM

|

|

CC Member

|

|

|

Join Date: Sep 2004

Location: Canberra,

ACT

Cobra Make, Engine: G-Force Cobra '68 302, T-5, Jag 3.77 LSD.

Posts: 993

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Rebel1

Keep in mind the trailing arm moves thru an arc therefore overtightening to increase toe and or squarness is not recommended.

Cheers

|

Les,

G-Force do not use original style trailing arms that project forward and mount under the driver's butt. They use bent/angled ones that project toward the tranny tunnel and pivot in the same axis as the inner control arms, forming a psuedo A arm, which does not stress the control arm or affect alignment through arm travel.

I would be interested to see Scotties modification, it wasn't too painful to get mine in square, with the body off using string lines.

If you plan to make "quick" adjustments to Camber with adjustable upper arms, don't forget this affects the TOE setting as well.

__________________

SLIPRY

|

07-22-2007, 05:57 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

David, that's the way trailing arms should work.

The RMC pivots under your butt hence moving in an arc changes the static length.

You know, if a manufacturer wanted to produce the perfect chassis they'd lock us all in a room, feed us heaps of crownies, give us a mountain of scribble paper and let us do our thing.

The more I hear about the G-force the more impressed I become.

My diff was a pain to get square. The top mount plate had moved during the welding process and using the tapered head jag bolts kept pulling the diff center out of square. Drilling the holes in the plate and using normal bolts with hardened washers fixed the problem.

Scotties modification is to machine the lower arm so it accepts a concentric bush/nut . The bush has a hex so when turned changes the toe. That bush/nut is then locked in place when the normal nut is tightened.

I'll send you a pic

Cheers

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

Last edited by Rebel1; 07-22-2007 at 07:54 PM..

|

07-22-2007, 06:46 PM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

Hmmm - sounds like some work ahead of me.

Would it matter whether this work was all down with the body on or off?

What I'm thinking here is to get the geometries set up to something acceptable and safe drivable for engineering / RW. I am planning to revisit back to a bare chassis for clean up and additions post engineering, and so I would tackle suspension set up properly at that time.

Clearly it is easier to work on the suspension without the body in place, but is this needed to get it all set properly? Or can it be a two stage process of set up to almost right, add body and bits and do final fine settings in this state?

Please advise so that I can plan a course of action that doesn't burn too much money revisiting the issue. I will visit a suitable alignment shop at the end to get it all accurate, I just don't want to be visiting them twice!

Cheers

__________________

slowy

|

07-22-2007, 09:29 PM

|

|

CC Member

|

|

|

Join Date: Sep 2004

Location: Canberra,

ACT

Cobra Make, Engine: G-Force Cobra '68 302, T-5, Jag 3.77 LSD.

Posts: 993

|

|

Not Ranked

Not Ranked

Slowy

The rear is easier to initialy set up and check with body off, but final adjustments front and rear will need to be done near finished with final ride height etc.

On my G-Force I had to slighty enlarge the holes in the top plate to rotate the diff slightly, and like Les, used flat shouldered bolts.

I wanted to change my diff from 3.77 to 3.54, but don't want the headache of re-aligning. It's not that drastic, just a pain in the butt lying on ya back.

__________________

SLIPRY

|

07-22-2007, 09:53 PM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

David

What you are saying is that the GF diff mount is out of square to the chassis the same as the RMC's?

If so, with the body off what's the trick to squaring it up?

I presume it's not so drastic that it needs to be changed before heading into engineering / RW first?

Cheers

__________________

slowy

|

07-22-2007, 10:11 PM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

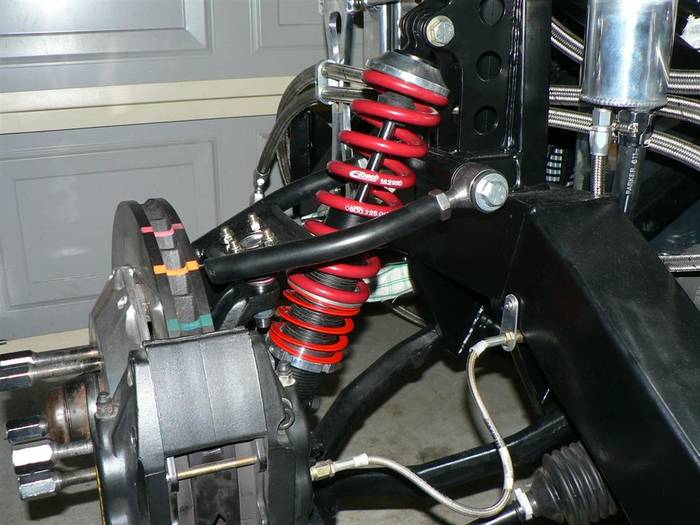

rear radius arm

rear radius arm

Check these radius arms I put on the rear.They have been on there for ever and I have no wheel hop and the rear is very stable.I made them myself very easily and they allow a little toe adjustment.check my gallery

Last edited by CHANMADD; 07-22-2007 at 10:22 PM..

Reason: add picture

|

07-22-2007, 11:51 PM

|

|

CC Member

|

|

|

Join Date: Sep 2004

Location: Canberra,

ACT

Cobra Make, Engine: G-Force Cobra '68 302, T-5, Jag 3.77 LSD.

Posts: 993

|

|

Not Ranked

Not Ranked

Slowy,

It was only out a poofteenth, but I thought if it's right from the start the less multiplication of errors.

I used a 1 metre square edge and a string line on the pinion flange to get the pinion parralell with the chassis. Then string line again on the hub flanges to set the toe-in. It was that close the alignment shop didn't need to alter it.

And who said string is only good for pulling tampons

__________________

SLIPRY

|

07-23-2007, 12:00 AM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by David Hodgson

And who said string is only good for pulling tampons  |

What's a tampon?

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

07-23-2007, 12:32 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Rebel1

What's a tampon?   |

The word tampon actually developed from the word "Tampion" which is a plug for the end of a naval gun to stop the ingress of water.

Check it out: Tampion

Cheers

__________________

Mike Murphy

Melbourne Australia

|

07-23-2007, 12:51 AM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

David

I sort of think that I know what you're talking about - that is to say "what the".

Got any pics or a diagram you can generate for me so I can picture what you did?

Cheers

__________________

slowy

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:48 PM.

|

|

might provide me with a greater confidence level as to whether the car will go around any corners I encounter.

might provide me with a greater confidence level as to whether the car will go around any corners I encounter.

Linear Mode

Linear Mode