Just an update on where I am with my Cobra project. First, ERA has indicated that they expect a shipment of pin drive wheels from Vintage in the near future. I'm hoping to get the rear wheels for my car as part of this shipment.

I am also knee deep in electrical work on my car. I am using a FAST XFI system and I've opted to build a custom wiring harness for the FAST XFI computer in my car to get a good fit and to ensure that there's not alot of visible excess wire from an over length wiring harness. I'm also using and MSD ignition system and I am implementing a number additional electrically controlled features based upon what my MSD Digital 6 Ignition and the XFI Computer can do. These include:

1) Using the red ignition indicator dash light on my ERA as a shift light controlled by the FAST XFI computer. This keeps the dash looking "stock". A hidden switch under the dash allows me to also use this light as a "Service Engine Soon" indicator from my FAST Computer. I will start the car with the light in the SES mode to check for any problems and then switch the light to be a shift light when I'm driving the car.

2) Using the 2-step REV limiter on my MSD Digital-6 and a shifter mounted button to implement a REV limiter for launching the car

3) I am connecting a driveshaft speed sensor to the XFI to implement electronic traction control as well as to implement recording of vehicle speed, tire slippage and gas mileage.

4) I am using a digital controller for my fuel pump which runs the fuel pump at a lower speed below 2,400 RPM to keep the fuel cool and improve fuel pump life.

5) I am also connecting a fuel pressure sensor to my FAST XFI computer so that it can monitor the fuel pressure on my car

6) The FAST computer can store up to 4 seperate programs for the fuel injection system. ERA made a custom control panel that is hidden under the dash which allows me to select which program to use. This lets me have different tunes in the car for street use, track use, and emissions and select the one I want with a flip of a switch.

7) I using the FAST XFI computer's internal data logging features to implement an on-board data logging system. This will include logging of all of the engine control functions as well as the driveshaft sensor and fuel pressure. This should be me a good platform to fine tune the car and deal with any problems that might come up later.

Here's a picture of the custom switch bracket which is hidden under the dash. These switches let me control all of the functions listed above from the driver's seat:

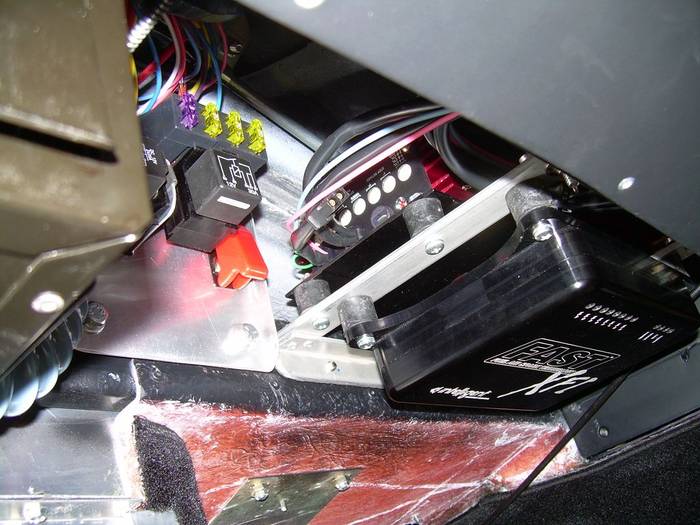

The following is a picture of the custom bracket that Doug at ERA made for my car. It mounts the FAST XFI computer (the black box), the MSD Digital 6 ignition box (the red box) and all of the fuses and relays associated with the FAST XFI computer (these are installed in the picture but not yet connected to the wiring harness). This computer is mounted face down so that the indicator lights on the FAST computer are easily viewed by looking under the dash. The entire assembly can be removed with 2 wing nuts to allow the settings on the MSD box to be easily changed.

Doug built a nice custom aluminum panel which mounts the FAST XFI program selector switch, an arming switch which allows the FAST XFI computer's software program to be updated, and an auxillary fuse block and Fuel Pump relay. This panel is hidden under the dash next to the XFI computer - again, we were able to add all of the extra electrical components to the car in locations which are not visible.

The final picture shows how all of these components are mounted together under the dash on the passenger's side of the car. This picture was taken before all of the wiring (and the XFI program selector) switch were installed. As you can see, everything is neatly hidden. Doug did a really outstanding job with this!

Obviously all of this involves an significant amount of custom wiring work. At this point I have about 50 hours in this part of the project. To give you a feel of the amount of work involved, there are over 100 wires that need to be terminated to build the FAST XFI wiring harness alone! At this point, all of the wiring for the ignition box and all of the in-car control features are done. I'm about 70% done with the custom harness for the FAST XFI computer and I plan to install the computer and the custom harness in the car for the last time this weekend. I was able to build the FAST XFI harness off the car thanks to the really neat removable bracket assembly that Doug created for the FAST computer and the MSD box. All of this may seem a bit complicated but the key to making a system like this work well and be reliable is to 1) use good electrical practices to build everything such as soldering connections, using heat shring tubing and high quality sealed connectors everywhere, etc. 2) test all of the components as you go (for example, I've tested the entire ignition system, fuel pump controller, tach, etc using an MSD ignition tester which lets me generate signals that trigger the MSD box and all of the PRM activated features; I've also brought the XFI computer up on the bench and verified that its working with the custom harness and that it can talk to my laptop, and 3) carefully document everthing via diagrams and tables so that you can remember what you've built later if there's a problem. At this stage, I need to put connectors on all of the wiring to the engine and to the driveshaft and fuel pressure sensors and I can fire her up! I think that I should be to this point by the end of this weekend if all goes well. I will post some pictures of the completed wiring to give everyone a feel for what was involved. A great deal of what I am doing is defintely not needed on most EFI equipped Cobras. Most folks would do fine to use a pre-built harness from FAST and would not try to utilize all of these electrical features that I am using. I'm trying to take maximum advantage of all of the capabilities that the electronics in my car can provide and also create a neat, custom installation that is completely hidden.

- Fred