Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

10-10-2012, 04:59 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Where to put water temp sensor?

Where to put water temp sensor?

I have a feeling I know the answer to this question but I'll ask anyway. I'm using an original low riser 2x4 intake and now that I'm preparing to install my dash panel I'm looking for a place to screw in the temp gage sensor. The only sizeable ports (one in top of intake and one in water pump) I have my heater hoses plumbed to. There is one boss and small plugged opening directly in front of the carburetor that looks to be in the water passage. I would have to drill this out considerably for the Smiths gage sensor and then vacuum out the cuttings.

Not being a Ford engine guy - is this my only option? I suspect it is. Or is there someplace in the block (428) it can go? I'll have to figure out what size that sensor is and see if I have a tap that big.

|

10-10-2012, 05:26 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,455

|

|

Not Ranked

Not Ranked

Ideally, you want the sensor somewhere near the thermostat; but certainly near the front/top of the engine.

I bet you could find a brass adapter at your local NAPA store.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

10-10-2012, 06:44 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

I have a feeling I know the answer to this question but I'll ask anyway. I'm using an original low riser 2x4 intake and now that I'm preparing to install my dash panel I'm looking for a place to screw in the temp gage sensor. The only sizeable ports (one in top of intake and one in water pump) I have my heater hoses plumbed to. There is one boss and small plugged opening directly in front of the carburetor that looks to be in the water passage. I would have to drill this out considerably for the Smiths gage sensor and then vacuum out the cuttings.

Not being a Ford engine guy - is this my only option? I suspect it is. Or is there someplace in the block (428) it can go? I'll have to figure out what size that sensor is and see if I have a tap that big.

|

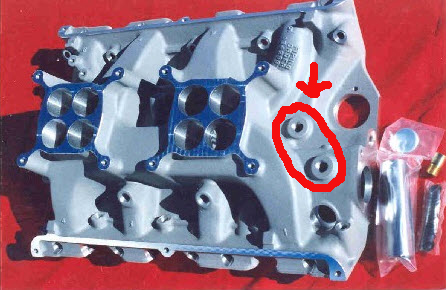

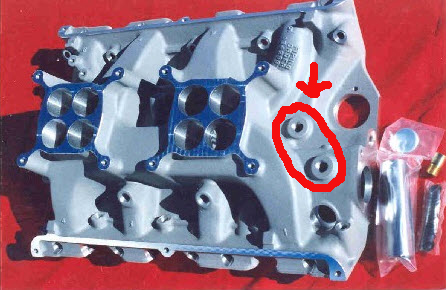

Do you not have these two holes up front? The top one takes the sensor, the lower one takes the heater hose fitting.

Last edited by patrickt; 11-03-2016 at 10:37 AM..

|

10-10-2012, 07:28 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Do you not have these two holes up front? The top one takes the sensor, the lower one takes the heater hose fitting.

|

Patrick - mine is a LR version, but yeah it has two ports like that. However the one on center is only drilled out to about 1/4 inch so I will have to do some heavy duty drilling and tapping for the sensor. I wish I had thought of this before the engiine was assembled. Oh well - where is my drill.

Dan |

10-10-2012, 07:39 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

Patrick - mine is a LR version, but yeah it has two ports like that. However the one on center is only drilled out to about 1/4 inch so I will have to do some heavy duty drilling and tapping for the sensor. I wish I had thought of this before the engiine was assembled. Oh well - where is my drill.

Dan

|

I guess you could put a shop vac in to the thermostat opening while you drill -- it might not be too bad. I don't know, maybe some of the machinists around here know some tricks for that.  |

10-10-2012, 08:09 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

I've taken a small piece of rubber tube and taped it up to a vacuum hose to vacuum a passage out before. This is manageable - just wanted to make sure I wasn't missing some other option before I break out the drill.

Thanks

|

10-11-2012, 04:06 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

it probably wouldn't matter which was the heater hose and temp port? use the hole closest to the thermostat opening..

|

10-11-2012, 06:01 AM

|

|

CC Member

|

|

|

Join Date: Jun 2002

Location: Canton,

GA.

Cobra Make, Engine: E.R.A. #505

Posts: 216

|

|

Not Ranked

Not Ranked

Grease on the drill bit will catch a lot of the shavings. This works good with a tap as well.

|

10-11-2012, 06:08 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by tboneheller

Grease on the drill bit will catch a lot of the shavings. This works good with a tap as well.

|

I haven't had time to measure the fitting yet - anyone happen to know what size hole and thread count for a tap is needed? Appears to be the same as for the heater hose nipples. I'm wondering if it's a pipe thread tapping also (NPT?). I will probably have to look around in Sears for one of those. |

10-11-2012, 06:18 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: West Chester,

PA

Cobra Make, Engine: ERA #795 427 S/C completed Jan. '14 - '68 FE 427 side oiler

Posts: 1,059

|

|

Not Ranked

Not Ranked

Hi Dan,

I'd suggest speaking with Doug at ERA if you haven't already. He could likely answer all your questions, including the type and size of the thread you'll need.

Regards,

Kevin

__________________

"Anyone who drives faster than you is a maniac and anyone who drives slower than you is an idiot" - George Carlin

|

10-11-2012, 07:03 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

using Patrick's pic as a guide i use the port closest to the distributor. that port will pick up the temp from crossover between the two heads.

and yes the thread is NPT, i think if i remember its 1/4 NPT if you buy a tap be sure its not just a carbon steel tap or you may break it off. make sure the tap package or the seller shows it to be HSS high speed steel.

use tapping fluid for lubrication or liquid soap if none is available. if you have any tube lying around use it as a sleeve for the tap to insure its going in straight...

__________________

Fred B

Last edited by FWB; 10-11-2012 at 07:11 AM..

|

10-11-2012, 09:08 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

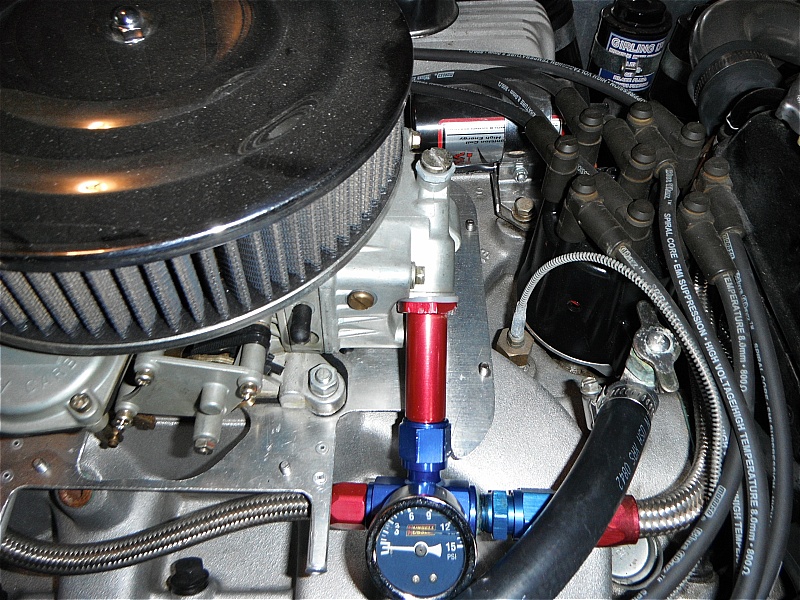

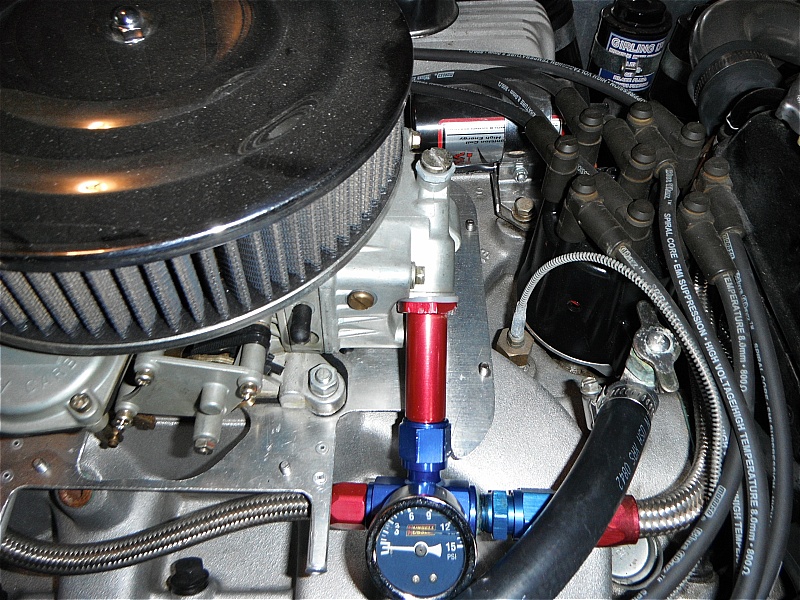

What should govern what port you choose for what is whether or not it will fit along with your fat little fingers. I'm assuming you're going to put a little shut off valve in the manifold -- they're only a couple of bucks from Summit -- but you have to make sure that you can reach your hand in there and that the handle of the valve doesn't hit something (like your front carb, or in my case a Turkey Pan, which is removed for this shot). Here's the shot of mine and you can see why it is why it is:

Last edited by patrickt; 11-03-2016 at 10:38 AM..

|

10-12-2012, 09:17 AM

|

|

CC Member

|

|

|

Join Date: May 2012

Cobra Make, Engine:

Posts: 57

|

|

Not Ranked

Not Ranked

That's an awful big tap. NPT isn't exactly the same as OD thread or root diameter, it's the nominal dimension for the inside of the pipe itself. 5/8" NPT is big - bigger than half inch water pipe. Which would mean adding the wall thickness and threads, too. That makes 3/4 pipe over 1" hole size.

Plus, I'm not sure how available 5/8" NPT is. NPT- National Pipe Thread Taper- ANSI B1.20.1

FWIW. |

10-12-2012, 10:34 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

I don't know if you're putting Smiths gauges in there, but I think my Smiths sending unit is UNF thread....  |

10-12-2012, 11:15 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

I have a standard water hose nipple that has a nominal diameter of 5/8 inch on the exterior of the threads - but it might actually be sized as something else - I'm not sure. I'm going to take the nipple down to Sears this afternoon and try to match it up against a tap - see if I have any luck. And then if I can match it up I hope the tap notes the size of drill bit I will need.

UNF threads - huh? Well, I guess they generally have screwed into the standard NPT hose nipple manifold opening or there would be a whole cottage industry built up around re-tapping out Ford intake manifolds. I will visually compare the nipple to the sending unit threads and see how they match up. But yes, they are Smith gages.

Thanks

|

10-12-2012, 11:20 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

UNF threads - huh? Well, I guess they generally have screwed into the standard NPT hose nipple manifold opening or there would be a whole cottage industry built up around re-tapping out Ford intake manifolds. I will visually compare the nipple to the sending unit threads and see how they match up. But yes, they are Smith gages.

|

This page says that UNF threads can only be used with other UNF threads....

McMaster-Carr |

10-12-2012, 11:36 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

If it was me, I'd call Peter up at Nisonger and ask him just what the deal is with the funky thread. I know he sells his Smiths stuff with your choice of either 5/8 UNF or 3/8 NPT temperature sensor fittings... so it just might make a difference. Certainly worth the price of call before you start carving.  Orrrrr, you could do like the rest of us and just jam the threads in good crossways, use a lot of leak-b-gone goo, and torque it down like crazy.  |

10-12-2012, 11:38 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

This page says that UNF threads can only be used with other UNF threads....

McMaster-Carr |

I don't think these are a fine thread tapping. I'm beginning to suspect they may just be a standard coarse UNC tapping (non-tapered) opening. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:44 PM.

|

Orrrrr, you could do like the rest of us and just jam the threads in good crossways, use a lot of leak-b-gone goo, and torque it down like crazy.

Orrrrr, you could do like the rest of us and just jam the threads in good crossways, use a lot of leak-b-gone goo, and torque it down like crazy.

Hybrid Mode

Hybrid Mode