Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2025

November 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

3Likes 3Likes

04-01-2016, 01:09 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

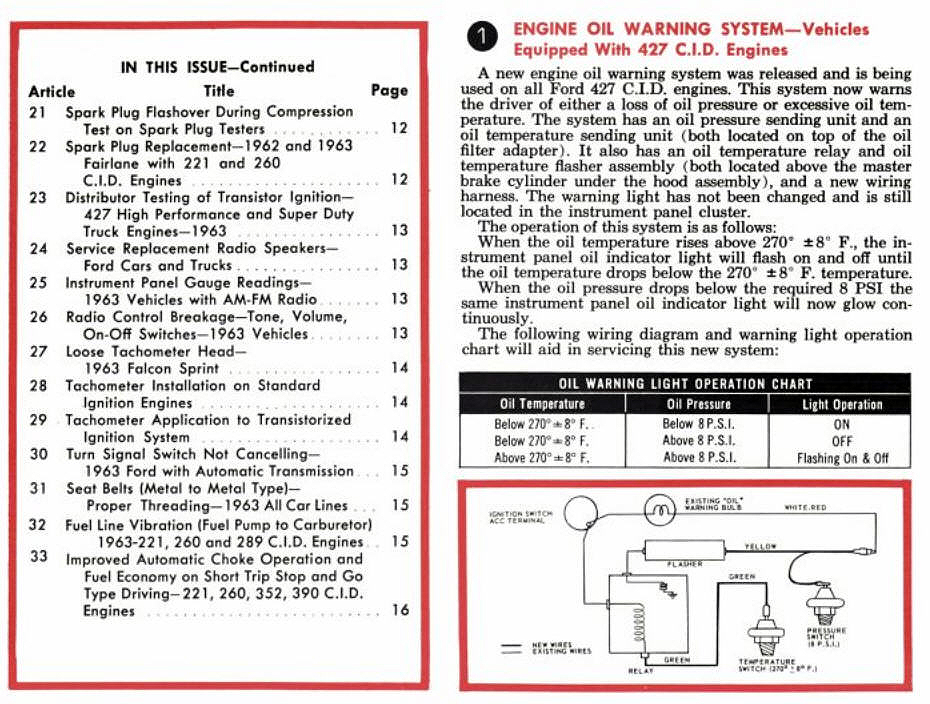

Oil Temp 265 Degrees and Pressure Only 9 PSI -- Did Ford Say That Was OK for a 427?

Oil Temp 265 Degrees and Pressure Only 9 PSI -- Did Ford Say That Was OK for a 427?

No, this is not an April Fool's joke, but it recently won a small wager for me.

Source: Shop Tips, Volume 1 Number 2, Ford Motor Company (November, 1963)

Source: Shop Tips, Volume 1 Number 2, Ford Motor Company (November, 1963)

Last edited by patrickt; 11-04-2016 at 09:59 AM..

|

04-01-2016, 01:38 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2005

Location: saratoga,

ca

Cobra Make, Engine: Kirkham #185, Shelby Alloy 482; sold

Posts: 1,190

|

|

Not Ranked

Not Ranked

Yikes, my oil pressure light is set to go on at 30psi. On hot days, with oil temp around 100c, it will flicker at idle.

__________________

Dave

Last edited by 4pipes; 04-02-2016 at 08:02 AM..

|

04-01-2016, 01:40 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 4pipes

Yikes, my oil pressure light is set to go on at 30psi. On hot days, with up oil temp around 100c, it will flicker at idle. |

Well, you, too, would have lost that bet.  |

04-02-2016, 06:23 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Patrick,

I would have lost that bet too regarding the oil pressure  It must be that the oiling system is so efficient that at 9 psi there is enough oil movement to privet total catastrophic failure? It would seem like it might be a possibility at low rpms, I cannot imagine the damage that would occur at high rpms with low oil pressure.

Where did you find that tie bit? You have too much time on your hands, go out for a drive! |

04-02-2016, 07:44 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

That is from the Ford Shop Tips, Volume 1 Number 2 (November, 1963) that Ford would send out to the dealer technicians. I think it's safe to say that the 9 PSI was at idle only.  I have the owner's manual from the same time period that clearly states "occasional flickering" of the oil light while idling is normal. Old Ford techs that worked at the dealers have told me that "we would go as low as 6 psi at idle, but below that was usually bad." |

04-02-2016, 12:26 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

Wow. I would have lost the bet as well! Did that apply to all 427's? Center-oilers and Side-Oilers? Just curious..

__________________

All that's stopping you now Son, is blind-raging fear.......

|

04-02-2016, 01:26 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

I always thought 20-40 psi was the rule of thumb. I sometimes run as high as 60!

__________________

All that's stopping you now Son, is blind-raging fear.......

|

04-02-2016, 01:40 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Bernica

I always thought 20-40 psi was the rule of thumb. I sometimes run as high as 60!

|

I think you should drop your oil pan, remove your bearings, drill some holes in them, then put them back in. That will let some of that needless hi-pressure out.  |

04-02-2016, 01:59 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

I use 20-50 and when the engine is cold it runs at about 80 psi and then when it is warm it drops to 60 psi, 40 psi at idle.

|

04-02-2016, 03:43 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

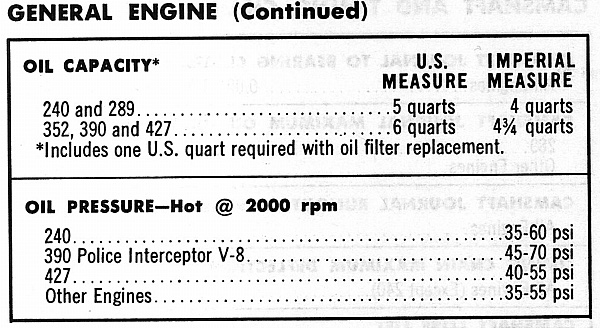

Straight from the Service Manual...

Straight from the Service Manual...

Last edited by patrickt; 11-04-2016 at 10:00 AM..

|

04-02-2016, 03:46 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

That's right about where I am.

__________________

All that's stopping you now Son, is blind-raging fear.......

|

04-02-2016, 04:11 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

Growing up, I had 390, 406, 428 and 427's and was always told 30 psi hot should be the norm. That was before the tricked out HV / HP oil pumps and special blend oils, so I agree. Today's builds are a different animal all together.

__________________

All that's stopping you now Son, is blind-raging fear.......

|

04-02-2016, 11:16 PM

|

|

CC Member

|

|

|

Join Date: Jun 2012

Location: Naracoorte,

SA

Cobra Make, Engine: CR Cobra 3169

Posts: 818

|

|

Not Ranked

Not Ranked

That's why we usually refer to them as idiot lights. Only really made for the general public when you loose total oil pressure, the light will come on. If they made it to go on at say 20 psi, then hot oil pressure on a worn engine would come on or flicker all the time. So they made it low enough that if the oil pump broke, it would come on. Same with alternator warning lights. Unless you broke a fanbelt, a alternator can stop charging , but the light won't come on. That's why gauges are so much more important. But then most of the public wouldn't know what they were supposed to be reading.

JD

|

04-03-2016, 01:56 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

JD,

"Idiot gauges"? I know where you're coming from, and I agree up to a point. I think I could never have too many gauges....but warning lights very much have their place as well.

Gauges are excellent for monitoring, but they don't tell you immediately that something is going wrong unless you just happen to be looking at the right gauge at the right time.

I broke a fan belt once (in the middle of nowhere), and what alerted me to the occurrence was the temp warning light coming on....and looking at the temp gauge showed that the water temp was at the top end of the scale (and I do scan gauges regularly).

The temp warning light was what averted major engine damage.

Incidentally, the temp warning light and the temp gauge were standard fit. I will have the same on my FIA build.

Cheers,

Glen

|

04-03-2016, 05:14 AM

|

|

CC Member

|

|

|

Join Date: Jun 2012

Location: Naracoorte,

SA

Cobra Make, Engine: CR Cobra 3169

Posts: 818

|

|

Not Ranked

Not Ranked

I really meant that only having the light won't show you what's going on. I agree that having both is ideal. Reading up on my Territory, that when the temperature goes to high, It will beep at you, then if you ignore that, then it starts cutting out cylinders, until you don't have any power. So hopefully you pull over and see whats going on. Having worked for the RAA for many years. It's amazing how many people keep driving, with the light on hoping to either get home or that things will get better by themselves, until the engine seizes up. One member had a faulty alternator, so I gave it a tap with a hammer, and it started charging. Usually worn brushes. A week later, he still hasn't bother fixing it, but kept hitting it until he put a hole in the side of the alternator.

JD |

04-03-2016, 08:22 AM

|

|

CC Member

|

|

|

Join Date: Nov 2000

Location: Flower Mound, TX,

tx

Cobra Make, Engine: Lonestar LS 427, Keith Craft 501,Toploader

Posts: 883

|

|

Not Ranked

Not Ranked

Agree with JD. Back in the day, it was common knowledge that if your "idiot" light came on it was generally too late. If you knew anything about engines at all, you knew enough not to wait until the "idiot" light came on to check your oil level, Even regular factory gauges in older american cars were never very accurate. We even believed that many oil and temp gauges were designed to stay in the middle regardless of what was really going on in the engine.

__________________

" It ain't no big deal"

|

04-03-2016, 10:24 AM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

Well....Mine has 20 psi at idle 900 rpm at 190 degrees .

With the high volume pump it keeps the oil flowing . Too much pressure ain't good either.Also if the oil going to the top is restricted .for solids .even at a low 9 psi , there is still enough volume going through.

|

04-03-2016, 10:55 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

What I like to see for my personal stuff and what the customers like to see are generally two different things.

Oil pressure takes horsepower. Most guys want to see 20-30 at idle and 70-80 at full song. I can oblige.

Just built a 409 inch Pontiac for myself a few months ago. With a standard volume pump, it was 55 psi hot, at WOT....measured at the filter.

Remember, you'll lose oil pressure from the front of the engine to the rear of the engine. Typically about 10-15 psi. Built a bracket race 408 Cleveland for a guy, it measured 55 psi at WOT crossing the stripe at 7500 rpm. That's measured at the rear of the block, opposite end of the pump. Bearings looked brand new on tear down.

Last edited by blykins; 04-03-2016 at 10:59 AM..

|

04-03-2016, 11:21 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

What I like to see for my personal stuff and what the customers like to see are generally two different things.

|

So, measuring at the top of the oil filter adapter, and this is for your own personal stuff only, say, maybe 15 PSI looks good to you at idle when it's nice and hot, and idling below 1000? |

04-03-2016, 12:34 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

The point of a bearing is to keep the rotating shaft from touching a housing that could be stationary (mains) or moving at a different speed (rods). The oil pressure is not what keeps the two pieces from touching.

If you think of two flat plates with oil between them, when one plate moves the oil molecule touching the moving plate moves with that plate and the oil molecule touching the stationary plate stays put with it. All the oil molecules between are moving at different speed (some speed between zero and the speed of the moving plate). Essentially there are different layers of oil moving at different speeds. This is causing the oil to shear. The shearing action acts like a wedge that lifts the plate. The higher the speed differential the more the wedge can lift. So the pressure is not what keeps the two plates separated. It is very similar to the hydroplane affect, like spinning a tire on water.

Oils have polymerized chains of molecules that are entangled. The shearing action straightens the chains and causes shear thinning (lower viscosity). The shearing action is a form of friction and causes heat, which further lowers the viscosity. The lower the viscosity the lower the wedging affect (the less lifting force to keep parts separated). If it wasn't for the heat, a small amount of oil could remain in the bearing indefinitely. However in an engine at high shear rates, the heat build up is very rapid. So, oil must be flushed through the bearing, at a rate that is fast enough to keep the oil from over heating and thinning out to the point of metal contact.

Therefore the pressure is not what is important. The flow is what is important. The flow can be measured by the pressure drop across an orifice (restriction). Flow is proportional to the square root of the pressure drop. If you consider the entire engine as the restriction, and consider the oil pan to be at a constant pressure, then the oil pressure reading is a pressure drop, and it is proportional to the flow. So the oil pressure is a very inaccurate poor mans measure of the oil flow.

Now the problem is that the pressure drop, flow correlation is different for different viscosity oils. The colder the oil the higher the viscosity and the higher the pressure drop for a given flow. The point to all this is that the pressure is not what needs to be measured. At a given temp on a given engine at a set of conditions a certain amount of oil pressure may be adequate. At a different set of conditions, twice that amount of oil pressure may result in an engine failure.

Also from one engine to another with different paths lengths, and clearances, the required oil pressure to meet the needed flow is different. The exact pressure needed for any one engine is a different number at different conditions. What is known for certain is that zero oil pressure is zero flow and a disaster in a short time. How much pressure is the minimum is a crap shoot.

If you are pumping any more oil volume than you need you are wasting Hp. One drop too little is disaster. With so many variables everyone wants to error on the side of pumping too much.

I'm surprised with all the EPA and other government requirements the manufactures haven't went with variable speed electric motors on both the oil pump and water pump to get better MPG.

Last edited by olddog; 04-03-2016 at 12:54 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:10 PM.

|

3Likes

3Likes

It must be that the oiling system is so efficient that at 9 psi there is enough

It must be that the oiling system is so efficient that at 9 psi there is enough

Hybrid Mode

Hybrid Mode