Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2026

February 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

07-24-2004, 01:21 AM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Goofy FE question, but need answer. :)

Goofy FE question, but need answer. :)

Ok, so I'm using a 390 for the time being, and it's one that I bought a year or so ago running and built fairly stout...10:1, 540 lift, 240 duration, runs and sounds pretty darn good.

Here's the wierd part. The guy I bought it from said it had a solid cam, and I have adjusted accordingly a couple times now, but when I went to fix a manifold gasket leak I noticed the lifters are hydrolic (correct me if I am wrong, but no solid lifter would have an oil hole on the side and the pushrod cup wouldn't have a retaining clip, correct?)...

So now what? The engine has run for several thousand miles with .022/.024 lash. Do I remove all the lash now or just keep it as it was? What procedure do I use if I now make a change to hyrolic specs? |

-

Advertising

07-24-2004, 06:22 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2000

Location: Las Vegas,

NV

Cobra Make, Engine: ERA 427 SO

Posts: 1,126

|

|

Not Ranked

Not Ranked

Brent, that IS a bit of an unusual situation you find yourself in...and it brings up a follow-on question: is it a hydraulic cam and lifters or is it a mechanical cam with hydraulic lifters?

If it is a hydraulic cam, I would be a little concerned about possible damage to the lifters from running at full extension for awhile (which brings up the question of the adjusters...did you have to screw them all the way out to make room for the lifter extension when you adjusted them?). Obviously, the "right" thing to do would be to do is pull the lifters and inspect, but because of the objective of the lash, I think you could do a normal hydraulic adjustment and run it for awhile...if there is damage it would show up in lifter noise or adjustment issues.

If it is a mechanical cam with hydraulic lifters...? Seems I've heard you can put hydraulics on a mechanical, but not the other way around...anyone know the answer to this one?

I guess I would want to first find out if it is a hydraulic or mechanical cam. Do you have the cam card?

__________________

Ken

|

07-24-2004, 07:08 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,618

|

|

Not Ranked

Not Ranked

Brent,

Ken is correct about you can run hydraulic lifters with a solid cam. I knew a guy here once who did it as he didn't want to mess with adjusting lifters all the time. He set it where the hydraulic lifters had enough clearance to work and that seemed to keep him from ever having to adjust. But I don't know if that would be good for any car that is going to turn high RPMs as he just ran his on the street and it never saw above 6,000. And I am really not sure what the advantage, if any would be. Check as Ken said and find out is the cam is mechanical or hydraulic. Since you are that far into it, it might be good to make sure the cam and lifters match.

Ron

|

07-24-2004, 07:13 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

Brent: A quick way to determine whether or not the lifters in your engine are solid or hydraulic is to pull a valve cover, then find a rocker arm whose valve is on its seat. In other words, there's a little lash at the rocker arm. Now, push the rocker arm so it's lighly against the pushrod, then push the rocker arm hard to see if there's any additional movement. If it's a hydraulic lifter there will be a slight amount of movement as you push the lifter plunger into the lifter body. If there's no movement no matter how hard you push, you've got solid lifters.

By the way, the term "solid" used in this context doesn't mean the lifter is one solid chunk, but it's hollow and the pushrod cup is fixed solid in the lifter body rather than sittting on top of a compressible plunger as with the hydraulic setup.

Hope that's a hint that works for you.

Tom

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

Last edited by speed220mph; 07-24-2004 at 07:25 AM..

|

07-24-2004, 07:57 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

Brent:

I found the same situation when I disassembled my 427!!

It had been built by a Kirkham sub-contractor who was no longer in business. The lifters had oil holes and push-rod cups held in with circlips. When I took them apart, NO Plungers!! I don't know if they were built that way, or if they were modified hydraulics.

I switched to hydraulic lifter cam and lifters and stashed the original cam and lifters. I'll have to dig them out and take another look out of curiousity. I'll let you know if I come up with anything interesting.

Ted

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

07-24-2004, 09:09 AM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Livermore,

CA

Cobra Make, Engine: ERA #629, BBM Side Oiler Block, 482ci, Richmond 5 speed

Posts: 853

|

|

Not Ranked

Not Ranked

Brent,

Your cam specs sound a lot like mine. I have an Isky with .535 lift and 240@.050, .022 hot lash. I also have the Isky solid lifters which do look like hydraulics complete with the retaining clip. I don't recall whether or not they had an oil hole on the side. But, like you, when I first saw them I said to myself "these are the wrong lifters - they sent me hydraulics." Upon closer inspection, like Tom said, I was able to confirm that the pushrod cup was affixed solidly in the lifter body and there was no movable plunger.

Chris |

07-24-2004, 10:05 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

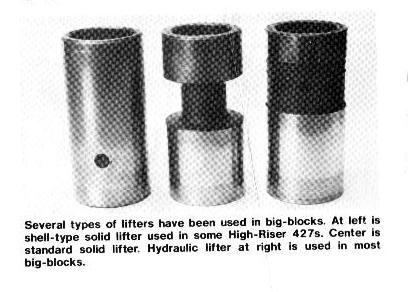

Brent: Speed220mph is right on, Motorhead and CJ428CJ have given a good description of the lifters themselves, the hole in the side of the body takes oil volume and pressure as it travels up and down and passes it through the orfice hole that the pushrod sits on, through the pushrod and to the pivot at the rocker arm adjuster top side. With the exception of 'Shell Type" the lifter bodies are often times the same with just a seat for the pushrod held in with a clip, and yes there may be a little movement in the seat itself. All of the internal adjusting and bleed down mechanism is added by the manufacturer IF they are to be Hydraulics.

Rick

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 07-24-2004 at 10:07 AM..

|

07-24-2004, 10:16 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

I'm pretty sure if they are WORKING hyd lifters you would have noticed major valve problems by now. With the .022 clearance and a hyd lifter functioning correctly the valve train noise would have been obvious! It would have clattered something fierce!

,,,,and thats NOT a goofy question, it's a great question. Now HERES a goofy one.

1. How much torque on the head bolts for a 427 side oiler?

2. Is the torque increased if the compression is over 12 to 1?

Bonus question:

Any of you guys RE-TORQUE your heads after running that new engine for a while?

Last edited by Excaliber; 07-24-2004 at 10:18 AM..

|

07-24-2004, 10:33 AM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

I believe that the solid lifters were made in two configurations,

1) Shell type lifter, with the pushrod seat deeper in the lifter. The lifter is like an inverted cup. They require a longer pushrod than the hydraulic lifters. I think these are lighter of the two versions, and I see alot of people prefer these over the 2nd type.

2) Standard lifter? type, that the pushrod seat is near the top of the lifter, like a hydraulic lifter, so they take the same length psuhrod, or near the same length. This is the type it sems you have. If you can't push on the pushrod end of the rocker to colllapse the lifter (if it's hydraulic), and you're still not sure, you can adjust the lash to 0, and then continue to tighten the lash. Either the lifter will collapse confirming a hydraulic lifter, or the valve will start to open, confirming a solid lifter. If you have a dial guage, you can set it on the valve spring retainer to detect movement.

I don't have a lot of experience with these engines, I'm still learning.

The other thing is the cam design type. I think hydraulic cams and solid lifter cams have different design style ramps and base circles, as the hydraulic lifter has always 0 lash. The ramps on the cam I think are designed differently to accomadate this, including the valve closing rates as well. I wouldn't run mixed parts, as you may damage the valves and seats. Cam manufacturers always state that you can't mix the parts.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

Last edited by Anthony; 07-24-2004 at 10:46 AM..

|

07-24-2004, 10:34 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2000

Location: Las Vegas,

NV

Cobra Make, Engine: ERA 427 SO

Posts: 1,126

|

|

Not Ranked

Not Ranked

Ernie brings up a thought, but I'm not sure if this is correct...isn't the 390 a mechanical lifter moter? If so, if you put hydraulic lifters in it, would they have the oil supply to "pump" up and function as hydraulica? If not, then they would act as mechanical lifters, right?

earnie, my book shows 100-110 ft-lbs for the factory head bolts (does ARP have separate specs? Don't know...), and I've never heard anyone recommend different torque numbers for higher compression...

Retorquing, I've heard yes and no, depending on the head gasket, but I think the phrase is "...retorquing is not necessary...", but I never heard any manufacturer say NOT to retorque...retorquing seems to be a good idea as a rule of thumb.

__________________

Ken

|

07-24-2004, 10:40 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Hmmmm,,,,, I was thinking the vast majority of 390's were hyd lifters. The 427's were mechanical only depending on year of motor, thus they required machine work if you wanted to run hyd lifters.

The "performance" 390's that pre-dated the 427 (EARLY 60's) were solid lifters.

I've never heard of anybody changing torque specs based on ARP bolts or high compression, just thought I'd check! I, for one, DO like to re-torque, I could be wrong.

|

07-24-2004, 11:08 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2000

Location: Las Vegas,

NV

Cobra Make, Engine: ERA 427 SO

Posts: 1,126

|

|

Not Ranked

Not Ranked

Ernie, you're right, had a brain fart here...only the "HP" 390s ('61-'63) were mechanical-lifter, the rest of the 390s were hydraulic.

__________________

Ken

|

07-24-2004, 12:58 PM

|

|

CC Member

|

|

|

Join Date: May 2003

Posts: 684

|

|

Not Ranked

Not Ranked

__________________

Bruce

Enjoyment may be 9/10's anticipation, but that last 10% is oh so sweet....

|

07-24-2004, 02:38 PM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Luke, the second type was called the "barbell" type, as you can see from the profile. The lifter Brent may have may be a full body outer shell, but with a fixed plunger inside, with the pushrod seat near the top. A solid steel lifter I think would be very heavy, so to make the solid lifter 2 piece would cut down on the weight, with havin a cavity inside the lifter. I would think tightening the valve lash until either the pushrod moves or the valve moves will determine what type of lifter, other than taking out the lifter itself and inspecting it.

I don't know if you can use the barbell type in a hydraulic lifter block, but I think you can use the shell type, and probably a full body solid lifter like what brent may have.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

Last edited by Anthony; 07-24-2004 at 02:41 PM..

|

07-24-2004, 02:55 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Brent Just look at the end of he push rod, If it has a hole through the middle it's hydrolic, if solid they are shell lifter that look like hydro's without the guts. Hydros are .300" taller the the shell lifters but look the same. How long is the pushrods? 9.157 that's a shell lifter but has a little play to adjust. Rick Lake ps I switch my motor over to real hydro lifters, you need to use SB ford lifters and hollow pushrods. If in doubt ask Joe or George.

|

07-25-2004, 01:01 AM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Thanks everyone...They are solids...Threw me for a loop as I had only seen the shell type solids on my other engines, so I thought for sure something was strange. All back together and running woderfully.  |

07-30-2004, 09:25 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: TACOMA,

WA

Cobra Make, Engine: Everett Morrision FE 427 so 2-4s

Posts: 2,025

|

|

Not Ranked

Not Ranked

Didn't Ford produce a T bird at least one year that had a Hydraulic lifter set up.That is what I remember maybe ( 68 or 69)something like 375 hp.

__________________

Mike H

|

08-09-2004, 10:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: Arkadelphia, AR,

AR

Cobra Make, Engine: Kirkham 427 brushed aluminum with Keith Craft 527C.I. all aluminum FE

Posts: 992

|

|

Not Ranked

Not Ranked

The lifters you have in your engine Brett are of the small block design with the oil hole for the pushrod oiling style valvetrain found on a small block Ford. They are the same diameter and about the same lenght as the regular lifter. They are easy to get and work just fine in FE engines. We have used them for years because the dump bell lifter were bad about breaking. Keith

__________________

Keith C

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:11 PM.

|

Linear Mode

Linear Mode