Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

March 2026

March 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

02-16-2008, 10:24 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Folsom,

CA

Cobra Make, Engine: ERA 623, 427 S/C Cobra. Ford FE 428 Cobra Jet, Ford Nascar TL 4speed - with a touch of raw; "less is more" theme

Posts: 3,887

|

|

Not Ranked

Not Ranked

UPDATE: AFTER THE REAL TEST DRIVE after REPLACEMENT of my faulty MSD CAP.

I would have never imagined that a change of my (second) 1.5 year old failing MSD distributor cap would have made such a bid difference as it turned out today. My car has not run this good as far as I can remember. I could feel the impact of every cylinder in the seat of my pants. What a lucky find. Runs great now. Still kinda shocked.

On a related note, I met with the NorCal Cobras group for our monthly and another guy comments about his car missing lately too; so the group of us standing there looks at each other and says "hey, let's go pull that MSD distributor cap too and see"... well all be darn, sure enough, same exact problem. The little carbon contact in the center was just like mine, totally disintegrated, gone, dished in, with bits of ash all inside the cap clinging to the contacts. DISINTEGRATED. Indexed or not, we need to figure out what the real root cause is here; otherwise these MSD caps are junk.

I will be keeping an eye on the Borg Warner cap to see if the same thing happens.

__________________

Duane

Western States Cobra Group 1998-2016.

|

-

Advertising

02-16-2008, 10:46 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Cobra Make, Engine:

Posts: 32

|

|

Not Ranked

Not Ranked

Here read this thread:

332-428 Ford FE Engine Forum

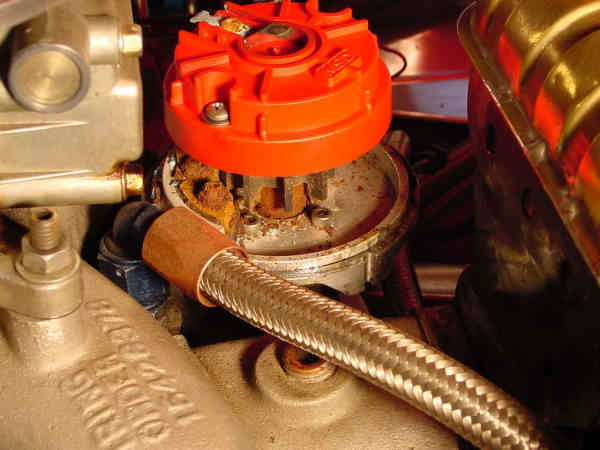

The spring arm on the rotor in my Mallory distributor wasn't touching the carbon button on the cap (about a .05 gap) and this is how they looked after less than 100 miles:

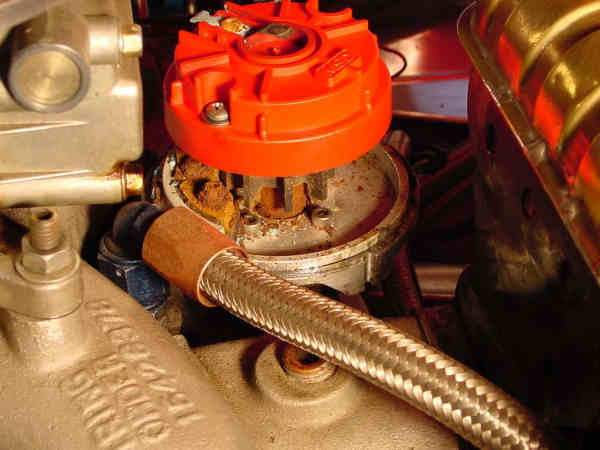

Here's a picture of an unused cap:

I think the arcing between the carbon button and rotor wears the carbon out very quickly. In the above pictures you can see the pitting/burning of the contact arm on the rotor and the cratering of the carbon button. |

02-17-2008, 03:22 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Folsom,

CA

Cobra Make, Engine: ERA 623, 427 S/C Cobra. Ford FE 428 Cobra Jet, Ford Nascar TL 4speed - with a touch of raw; "less is more" theme

Posts: 3,887

|

|

Not Ranked

Not Ranked

By Design?

By Design?

Makes sense. Nice Network 54 thread. Thanks. Bend that tong up!

Hmmmm. Maybe the reason that MSD does not tell anyone in their directions to check/bend the tong up, or to drill holes in the cap to let the ion gas out, is so we al have to buy new caps and replace their distributors every so often. Just like light bulbs; i.e. engineered that way.

__________________

Duane

Western States Cobra Group 1998-2016.

|

02-17-2008, 07:10 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Cobra Make, Engine:

Posts: 195

|

|

Not Ranked

Not Ranked

I had the same problem with the MSD in my Boss 429,can someone give me the part number of the aftermarket black cap that replaces an 8431 MSD cap.

Thanks

|

02-17-2008, 07:42 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Glendale,

AZ.

Cobra Make, Engine: Cobray-C3, The 60's body lines on todays chassis technology

Posts: 2,302

|

|

Not Ranked

Not Ranked

read MSD notice below

Carbon button - distributor cap - MSD Ignition Tech Support Forums

Assuming that the carbon button was not damaged in transit, the only thing that I can see that would cause the carbon bushing to prematurely wear would be if the rotor tab was not making firm contact with it. If the energy was arcing from the bushing to the tab this will cause the carbon to wear away quickly. Upon installation of a new rotor (in any installation) we do recommend verifying that the tab is making firm contact. One way to do this is to apply a small dab of dielectric grease to the tab, set the cap on as if it was installed, remove the cap and look at the impression in the grease. You should have an indention down to the metal, if not you may need to bend the tab up slightly in order to get the proper tension on the tab.

The post is not a servicable item, there is no replacement part for it.

__________________

MSD Tech Support

915-855-7123 |

02-17-2008, 09:19 AM

|

|

CC Member

|

|

|

Join Date: Sep 2003

Location: San Jose,

Ca

Cobra Make, Engine: SPF #1436 514

Posts: 1,489

|

|

Not Ranked

Not Ranked

My MSD cap has a stock vent hole!

Scott

|

02-17-2008, 01:19 PM

|

|

Senior Dragontamer

|

|

|

Join Date: Dec 2001

Location: Alvin,

TX

Cobra Make, Engine: Kirkham, 427 S/O

Posts: 271

|

|

Not Ranked

Not Ranked

I've had the same problem and go through caps way to often. I'll check the gap, thanks guys.

Jeff

|

02-17-2008, 02:11 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Glendale,

AZ.

Cobra Make, Engine: Cobray-C3, The 60's body lines on todays chassis technology

Posts: 2,302

|

|

Not Ranked

Not Ranked

I have gone through way too many caps before learning why and how a simple check stops this failure. It kinda puts me in a funk with MSD and feel a simple note in instructions or in their catalog is needed.

Since I had junk caps sitting around I also drilled one out to check rotor phasing and was amazed how far off I found many rotor tabs too be. Most engines did run without cross spark or missing but ...geeez! You can not move the pick up enough to change much and swapping to another distrib. is the only cost effect fix (they do now sell a 2 piece unit $$$$). You can tweak the Vac. Advance plate to help a little.

The caps are drilled with a 1/8 vent hole to remove ionized gas/air but I am also seeing what looks like rust or a coating that covers the internals and especially the pick up wheel. Spraying everything with spray silicone and then wiping the wheel ends clean seems to reduce this but anybody know why or what is happening? I am seeing this in Arizona (its a dry heat ya know) so does not seem to be humidity related.... Any ideas guys, need your help on this one. I have drilled a second vent hole but no real affect seen.

Last edited by vettestr; 02-17-2008 at 02:15 PM..

Reason: defective keyboard ..a lot of spelling errors sorry

|

03-08-2008, 08:42 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Avondale,

Pa

Cobra Make, Engine: Contemporary, Shelby Alum 427, Dove heads

Posts: 55

|

|

Not Ranked

Not Ranked

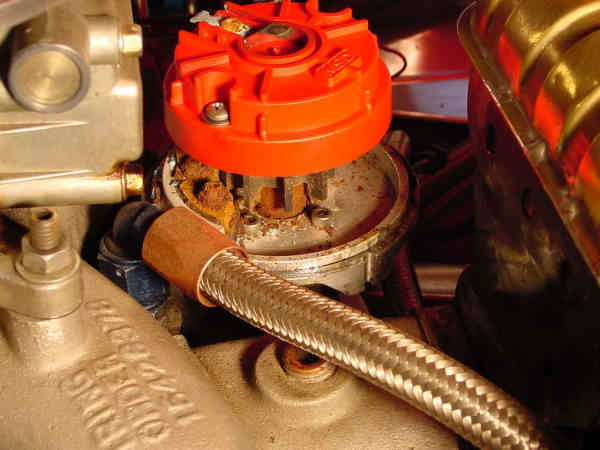

You mean like this.

I couldn't get the car to start, when I pulled the cap this is what I found. This cap is less than 500 miles old. MSD 8594 dist with MSD 6AL box and blaster coil.

The cap is vented, tomorrow I will cut a window in the side of the cap so that I can see what is going on. I have a feeling that the rotor may be lower than the cap. I think I will look elsewhere for a distributor. My last distributor looked like this after two years.

MSD said it was from ozone and an unvented cap. I replaced it wth a new distributor and a vented cap and yes the new one is rusting also but the cap failed first. Search the MSD forums for rust, you might be surprised at what you find. MSD solution, drill some holes in the cap and pull the distributor, press the gear off the shaft and clean it. Apply some dielectric grease and drill a new hole for the gear retaining pin. The new hole does limit how many times you can do this.

__________________

In school 90% is exceptional, in life 10% wrong is failure.

|

04-13-2008, 12:51 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Folsom,

CA

Cobra Make, Engine: ERA 623, 427 S/C Cobra. Ford FE 428 Cobra Jet, Ford Nascar TL 4speed - with a touch of raw; "less is more" theme

Posts: 3,887

|

|

Not Ranked

Not Ranked

Still researching this...trying different stuff, and comparing results

Still researching this...trying different stuff, and comparing results

I tried the Borg Warner aftermarket cap, and with more research found multiple instances where people are indicating the problems occur with these MSD caps for two primary reasons.

1. Tab on rotor not bent up and not aligned properly; arching. Degrading center carbon terminal (as confirmed here on CC too)

2. Corrosion, dampness, rust, and evidence of deterioration inside of cap (ion gas, etc.)

One issue I have with using one of the stock Chevy replacement caps from Kragen or Parts America or other places is the springs don't seem to have quite the same amount of tension as the MSD cap does. They work, but seems like they should be a tad more snug on the disributor. Since I use the older style male wire setup, not the HEI terminal type, so if my cap goes bad I can use a standard Chevy cap in a crunch from any local parts store. So, I'll keep my BW cap as a spare and try the new MSD one.

So, just for the heck of it I just ordered one of the NEW " MSD Extra Duty Distributor Caps" with (reportedly) improved terminals and lots of obvious vent holes in it. Look at the picture, there are large 1/4" diameter holes in the top of the cap and all they way around the cap. That's quite a bit of venting, i'll give it a shot and compare use/corrosion over time to see if it's any better or not.

Distributor Cap, Alkyd, MSD Chevy V8 Distributor Vented (8438)

Footnote: Quote: "MSD Extra Duty Distributor Caps are designed with performance in mind and are molded from high quality, voltage insulating material and use low resistance terminals", unquote. For Ford FE 332-428.

---------------------------------------------------------------

Link: http://www.shopatron.com/product/pro...=MSD8438/424.0

You can get it for less at Summit, but this link was right off of the MSD website for information reference.

__________________

Duane

Western States Cobra Group 1998-2016.

Last edited by decooney; 04-13-2008 at 12:56 PM..

|

04-13-2008, 01:06 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Avondale,

Pa

Cobra Make, Engine: Contemporary, Shelby Alum 427, Dove heads

Posts: 55

|

|

Not Ranked

Not Ranked

Maybe MSD could redesign the rotor to give it some airfoil. Then it could suck fresh air in through the bottom vents and blow it out the top  . I have had a lot of problems with rusting and carbon button failures. The MSD solution of providing vent holes seems like one designed for the lab and not really for the general market. I sure hope you don't get caught in the rain, the FE tends to lead with the distributor. I used the same MSD 6al box and blaster coil with my Mallory distributor and never had any problem. I got talked into the MSD pro billet and I will be switching back when my new MSD cap fails.

__________________

In school 90% is exceptional, in life 10% wrong is failure.

|

04-13-2008, 02:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Folsom,

CA

Cobra Make, Engine: ERA 623, 427 S/C Cobra. Ford FE 428 Cobra Jet, Ford Nascar TL 4speed - with a touch of raw; "less is more" theme

Posts: 3,887

|

|

Not Ranked

Not Ranked

Yeah, it's more of an experiment on root cause analysis at this point.... I tend to latch on to these things and won't let go until I've proven to myself in a repeated scenario what the final results are; even after I know the answer - still more validation. I'll run this setup for a year, and if it fails, the MSD distributor will go on eBay for highest bidder and I'll try my friends trick of using a stock Ford Duraspark disbributor and wiring in the MSD. He's not had a single distributor unit or distributor cap fail on him to date over the last 10 years when hooked to the MSD 6AL boxes. Plus, it looks more original anyhow. Some of these super-duper-billet-hyper-extreme-performance parts can be a little over rated at times. We'll see.

__________________

Duane

Western States Cobra Group 1998-2016.

|

04-13-2008, 04:14 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: Fresno,

CA

Cobra Make, Engine: Shelby CSX 4766 (Vegas Built) with 482 Aluminum Pond motor

Posts: 814

|

|

Not Ranked

Not Ranked

"I have had a lot of problems with rusting and carbon button failures."

Rusting is normal given that the part that is rusting is bare iron and should not effect performance.

However the cap is another story all together. I have just installed my 3rd MSD Cap with less that 3000 miles all because that stupid little button.

I am thinking class action lawsuit against MSD!

__________________

Morgan LeBlanc

Fresno CA

|

04-13-2008, 05:43 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Avondale,

Pa

Cobra Make, Engine: Contemporary, Shelby Alum 427, Dove heads

Posts: 55

|

|

Not Ranked

Not Ranked

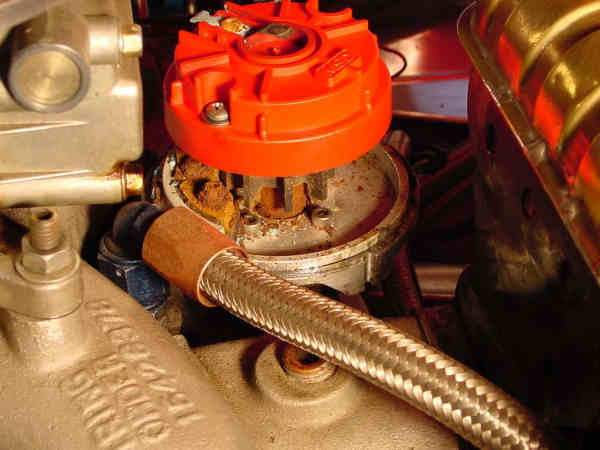

RedCSX1, your idea of acceptable rusting is probably not what my distributor looked like after two years. I was completely shocked at what I found when I pulled the cap. MSD blamed it on a non vented cap and excessive plug gap.

I replaced the distributor and had the carbon button fail, twice, MSD blamed that on a possible crack in the button from shipment or excessive spark plug gap. I cut away my old cap and took this picture with a new rotor installed. This gap is much bigger than my plug gap and most likely the cause of the ozone production. What does not show up here is that the rotor is also lower than the post. The carbon button is making very good contact with the rotor

I am convinced that MSD is trying to ignore a big problem, class action suit is not out of the question as far as I am concerned.

__________________

In school 90% is exceptional, in life 10% wrong is failure.

Last edited by edwhite7; 04-13-2008 at 05:48 PM..

|

04-13-2008, 05:55 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Folsom,

CA

Cobra Make, Engine: ERA 623, 427 S/C Cobra. Ford FE 428 Cobra Jet, Ford Nascar TL 4speed - with a touch of raw; "less is more" theme

Posts: 3,887

|

|

Not Ranked

Not Ranked

Engineers hard at work designing enough failure points into the components so we can buy replacement parts every year.

Or, maybe it was a problem that I accidentally stuck my distributor cap in the microwave instead of my cup of coffee a few months ago.  Maybe I was just expecting a light bulb that did not wear out, ya know, like the first one that Thomas Edison created.

__________________

Duane

Western States Cobra Group 1998-2016.

|

05-01-2008, 11:55 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: Phoenix,

MD

Cobra Make, Engine: ERA 427 SC

Posts: 100

|

|

Not Ranked

Not Ranked

MSD = Many Suspicious Devices

__________________

ERA #509

2003 Z06

|

05-01-2008, 12:25 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2000

Location: Gilford,

NH

Cobra Make, Engine: FFR 302 carb

Posts: 8,121

|

|

Not Ranked

Not Ranked

Duane,

While not a big block. I have been running a Duraspark Distributor with MSD box and coil for the past 7 years. Absolutely no problems.

Mike

|

05-03-2008, 09:13 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Folsom,

CA

Cobra Make, Engine: ERA 623, 427 S/C Cobra. Ford FE 428 Cobra Jet, Ford Nascar TL 4speed - with a touch of raw; "less is more" theme

Posts: 3,887

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Loadco

MSD = Many Suspicious Devices

|

or MSD = May Self Destruct!

...as engineered by design, so you have to buy another distributor cap.

__________________

Duane

Western States Cobra Group 1998-2016.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:59 AM.

|

. I have had a lot of problems with rusting and carbon button failures. The MSD solution of providing vent holes seems like one designed for the lab and not really for the general market. I sure hope you don't get caught in the rain, the FE tends to lead with the distributor. I used the same MSD 6al box and blaster coil with my Mallory distributor and never had any problem. I got talked into the MSD pro billet and I will be switching back when my new MSD cap fails.

. I have had a lot of problems with rusting and carbon button failures. The MSD solution of providing vent holes seems like one designed for the lab and not really for the general market. I sure hope you don't get caught in the rain, the FE tends to lead with the distributor. I used the same MSD 6al box and blaster coil with my Mallory distributor and never had any problem. I got talked into the MSD pro billet and I will be switching back when my new MSD cap fails.

I am convinced that MSD is trying to ignore a big problem, class action suit is not out of the question as far as I am concerned.

I am convinced that MSD is trying to ignore a big problem, class action suit is not out of the question as far as I am concerned. Maybe I was just expecting a light bulb that did not wear out, ya know, like the first one that Thomas Edison created.

Maybe I was just expecting a light bulb that did not wear out, ya know, like the first one that Thomas Edison created.

Linear Mode

Linear Mode