Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

5Likes 5Likes

03-21-2017, 01:31 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Keller,

TX

Cobra Make, Engine: Lonestar Classics LS427. Self-built 408W, AFR 195 heads, Performer RPM Intake, Quick Fuel 750, 407rwhp, 479rwtq

Posts: 549

|

|

Not Ranked

Not Ranked

You need to measure the distance from your mounting plate to the front edge of your flywheel teeth. The long end if some dial calipers are great for this. It needs to be within 1/16" of spec, depending on your motor and starter model. If you're distance is under spec, you as the shim.

I'm a Family Practice doc in Ft. Worth.

Edit: Here are the instructions for your starter: http://www.powermastermotorsports.co...ockingInst.pdf

Last edited by Texasdoc; 03-21-2017 at 01:59 PM..

|

03-21-2017, 01:34 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

OK, thanx so much. steve

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

03-21-2017, 01:42 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

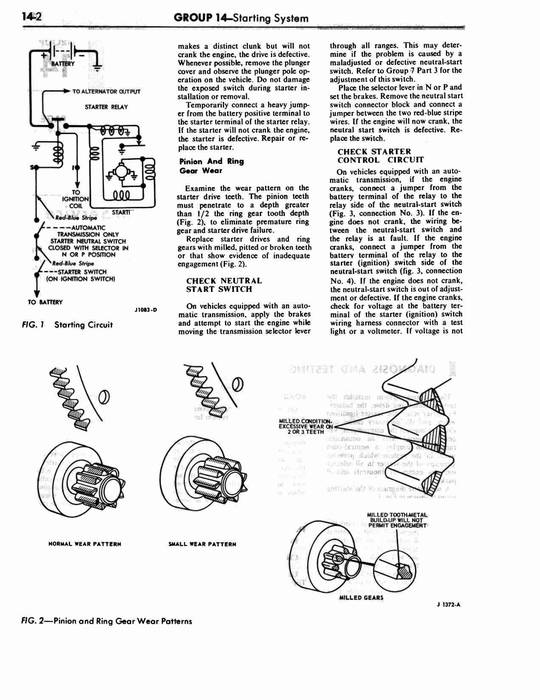

Peeking in and looking at the flywheel teeth will also tip you off as to how they are engaging. Here's the Ford Shop Manual, circa 1966, page on gear engagement that I had copied for someone who had a similar problem a few years ago. From those pics you posted, you kinda look like the "small wear pattern."

|

03-21-2017, 02:05 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Keller,

TX

Cobra Make, Engine: Lonestar Classics LS427. Self-built 408W, AFR 195 heads, Performer RPM Intake, Quick Fuel 750, 407rwhp, 479rwtq

Posts: 549

|

|

Not Ranked

Not Ranked

It does look like the small wear pattern, but as far as I know, there is no adjustment for that. That is dependent upon the relationship between your flywheel and the starter mounting location. As far a the SBFs, those are set by the bell housing and engine plate and are fixed in location. I don't know if they make offset bolts to correct that or not (kinda like how you would center a bell housing to the crank with offset dowels).

Just guessing here and maybe someone else will chime in with the right answer, but you can ask PowerMaster if they have a slightly larger drive gear to increase gear mesh/engagement...???

Edit: Doing a little research - it looks like the FE's used different size flywheels for different blocks. You should count the number of teeth your flywheel has to be sure. Since you have the starter off, mark one tooth with liquid paper (White-out) and slowly rotate the motor with a wrench on the crank bolt. Count the teeth until you get back to your mark. That way you know for sure.

Here is a link (Clicky) from ffcars forum that talks about BBF starters/flywheels/bell housings. I don't know if the difference is just the size of the mounting plate, bolt hole locations, or depth of the drive gear. Check yours to make sure you have the right one. Also, you do have the motor plate installed between the block and the bell housing, right?

Last edited by Texasdoc; 03-21-2017 at 02:35 PM..

|

03-21-2017, 02:27 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Texasdoc

Just guessing here and maybe someone else will chime in with the right answer, but you can ask PowerMaster if they have a slightly larger drive gear to increase gear mesh/engagement...???

|

If you find the wear pattern is unacceptable, and you find that it's not adjustable somehow, and PowerMaster won't help you, then I would contact Robb Mc -- his starter gets very high ratings over on the FordFE forum and he will make you a custom drive gear that fits perfectly with your tolerances. I only know that though from reading years of posts over on the FE forum; no personal experience. Although i do use Erson roller rockers, which he designed. Here's his site if you decide to go that way:

Welcome to RobbMc Performance Products |

03-21-2017, 03:26 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

i have the motor plate and will try to count the teeth. thanx for the info and the starter instructions, which i'm sure are buried in my file drawer, somewhere. s

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

03-21-2017, 03:59 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

At this rate, you're liable to find a couple of chipped teeth off of the flywheel, so we'll have to pull the transmission out to get the bellhousing off to get to it, then we'll use the wrong pilot bearing putting it back in and fry the thrust bearing on the crank, and maybe drop the trans on the side of the car, then from there we can break the cam, water pump, and create some intake leaks. Yessirrreee, I think this little fuel pressure fix up is good for another two years worth of work....  |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:07 PM.

Links monetized by VigLink

|