Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

01-10-2011, 04:44 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

victor1,

I'll need some time to digest all of that, thanks.

|

01-10-2011, 08:21 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 1999

Location: Fallbrook, CA USA,

CA

Cobra Make, Engine: Porsche 928 S4

Posts: 739

|

|

Not Ranked

Not Ranked

Gentlemen,

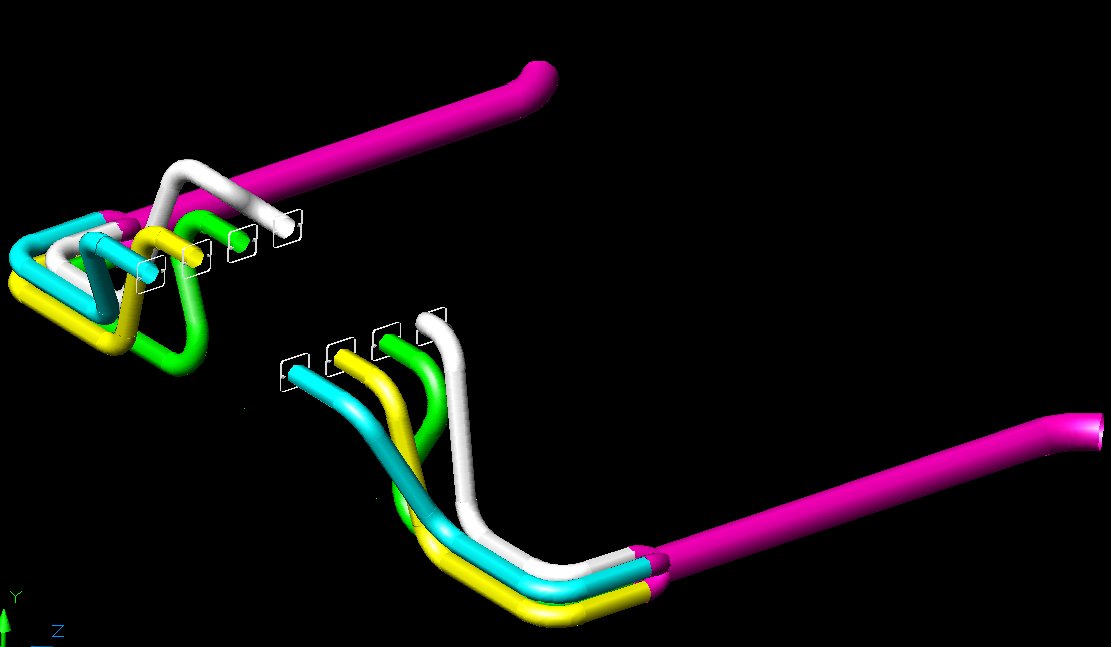

Here are some views of the original design headers and sidepipes for the JBL Chassis.

Note: Primaries are 1.75 X 35 inches Secondaries are 3 X 34 inches. These are not the same as current as the rear most tube does not go up and over the engine bay upper rail as this was difficult for changing plugs.

However the current units should still be close to the lenghts of the original design. |

01-10-2011, 08:34 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Highland,

MI

Cobra Make, Engine:

Posts: 221

|

|

Not Ranked

Not Ranked

Guys, I did an installation (retrofit) on a Ford 514 CID Factory Five on Saturday - a local guy's car in his garage. We did this on the car so we could get actual alignments & fitting. It took us 3 hours & the car owner did not have an air compressor. He went with the 3024-CP mufflers & will see a noticeable improvement. Wait til you see the entry into the mufflers after we chopped the collector & muffler apart - this is the kind of stuff I've been talking about. Also, the muffler cores looked to be about 2-1/4", so we stepped up to 3". After our tack-together mockup, he's going to take them to a welding shop & have all the seams finished with professional TIG welds, then have them ceramic coated. I got everything over to my web builder last night - a pretty nice series of photos. We will have a whole new page dedicated to retrofitting a Cobra with COBRAPACK Mufflers. This should all be up in a few days. ( www.classicchambered.com)

Also, the reason why Kinetic had such huge gains in HP & torque, is because they had been using the stock Cobra mufflers which had under a 2" flowpath. On their high HP motors, this was REALLY choking the motors - they could not exhale. When they did this dyno testing, my 3" core mufflers were even more of a restrictive design than they are now - now they are very clean & maintain a consistent diameter. The same tests now would yield even better results. Chris Gesek (one of the owners of Kinetic) furnished me with the dyno #'s. There was no fudged data. Shows you just how important it is to run good flowing mufflers!

Thanks, -Eric |

01-10-2011, 08:39 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Richard,

Excellent, thanks for posting that! While we're on the subject, what is your opinion of the 'stainless steel' versus 'ceramic coated mild steel' dissertation below?

Stainless Steel vs. Mild Steel - http://www.perfweldheaders.com/svsm.html

A very popular question concerning the use of Stainless steel over Mild steel in a Competition Header application constantly arises in the industry. Stainless Steel is a better choice when Header lifespan, updates, and quality are an important consideration. A Stainless Steel Competition Header, when properly built, will virtually last you a lifetime.

A Mild Steel Header in a Competition application will soon take its toll from the elements of high exhaust temperature and rust. Performance Welding has tried many Exhaust Coating manufacturers and have found none that will withstand the extreme temperature of a competition engine. On the inside of the primary tubes and at the throat of the Merged Collector, the thermal barrier coating simply cannot withstand the high temperature and after a very short period, the coating burns off and rust begins to generate.

This rust can be disastrous to any engine and can ruin many components.

On initial overlap, there is an inevitable reversion pulse that can send exhaust back up the intake tract. If the rust loosens in the header primary tube it can, and sometimes, will carry some of this abrasive material into your cylinder.

It is highly advisable after leaving Mild Steel Competition Headers over a period of time to take any precautions to remove the rust build up; on initial engine start up this rust can be disastrous.

Stainless Steel Headers have many benefits outweighing the initial cost increase. Due to the fact that they do not need a Thermal Barrier coating you save a few hundred dollars on the initial cost. Stainless Steel Headers can be repaired, or modified at any time in their lifespan due to the simple fact that they do not rust and do not need a Thermal coating. Mild Steel Headers are very tough to repair or modify due to Thermal Coatings and rust.

It is believed that due to Stainless Steel Thermal characteristics, the high exhaust temperature is retained inside the primary tubes and can increase the exhaust speed in the header, which in a Competition Racing Header sometimes is an important goal. Due to the simple fact that there is no rust generated, the inside of each primary tube will stay smooth and flow accordingly.

Performance Welding Racing Headers feel strongly about the use of Stainless Steel in your Competition Header application. If you have a Race vehicle that you truly wish your Competition header to last a lifetime, or if we have a proven Competition Header for your engines combination, or you simply like the benefits of Stainless Steel we highly recommend it in any Competition Header application.

- Mark Lelchook / Owner

|

01-10-2011, 09:07 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Man, the information highway is open tonight!

Eric, thanks for the info.

I hope you see this gapingly large hole in the current Classic Chambered business model like I do ...

"he's going to take them to a welding shop & have all the seams finished with professional TIG welds"

|

01-10-2011, 10:16 PM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

these guys make some pretty nice looking stuff, with replaceable packing.

http://www.coastfab.com/index.html |

01-11-2011, 09:15 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Highland,

MI

Cobra Make, Engine:

Posts: 221

|

|

Not Ranked

Not Ranked

The new page is up - step-by-step on the retrofit with a bunch of photos.

|

01-11-2011, 03:52 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 1999

Location: Fallbrook, CA USA,

CA

Cobra Make, Engine: Porsche 928 S4

Posts: 739

|

|

Not Ranked

Not Ranked

Machiavelli

As to the statements about stainless as a header material the following:

The Thermal Conductivity - k - (W/mK) of various materials used in headers are as follows:

Carbon Steel 54

Ceramic coated Carbon steel 2.36

Stainless Steel 16

Inconel 8.4

Note: 1 W/(mK) = 1 W/(m degrees C) = 0.85984 kcal/(hr m degrees C) = 0.5779 Btu/(ft hr degrees F)

It is true that stainless makes a longer lasting header then carbon steel under racing conditions. The life increase is minor in my experience and I have had many problems with cracking at welds due to differential material thermal expansion of the base and filler alloys. (This can be a problem with carbon steel as well if you use a really wrong filler material but this is rare)

I have had the best luck with Inconel for race headers. I have never had a crack or failure of any type using this alloy. It is used by all of the F1 guys and most LeMans Prototype cars as well as the turbocharged engines in many series.

Also you still need a thermal barrier with stainless. They still heat up to match internal temperature it just takes a 3.5X longer than plain carbon steel. Also the lower heat conductivity makes them take much longer to cool down which can give you problems with shutdown heat soak. (This is also true for Inconel and why you see the F1/LeMans headers in a gold foil lined and covered containment.)

Whereas ceramic coated carbon steel takes much longer to achieve 100% heat soak and typically never does due to duty cycle and airflow removing the transferred heat away at almost the same rate as conductivity.

I would still use the ceramic coated carbon steel if I were you. The heat transfer normal to the wall is the lowest of all and will keep under-hood temperatures down. (By a factor of 4 relative to stainless from the above table.)

You must remember that you are normally going to be running at part throttle and your exhaust temps are going to be quite low. (Street use)

For the times that you are going to do track work your full throttle time will seldom be over 60% of a given lap and I doubt that you will be putting in more than 10 lap stints. Overall header temperature or corrosion should not be a real factor in the life span of your system.

But you can make stainless units and then ceramic coat them and have, as Dr. Pangloss in Voltaire's Candide so eloquently stated, the best of all possible worlds.

(The real best would be ceramic coated Inconel $$$$$$$$$)

With any luck this will make some overall sense.

Last edited by Richard Hudgins; 01-11-2011 at 05:36 PM..

Reason: spelling

|

01-11-2011, 06:08 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Richard,

Another great post, and it does make perfectly good sense. I hadn't considered the heat soak issue, that alone is a show stopper for me. But as you have said, there is this 2nd "best of all possible worlds" option (leaving Iconel out of it), that being ceramic coated SS. Back on post #12 I mentioned I've been digging more into side pipes, have emails out to some of them. One looks interesting, cutting edge - but we'll see. I actually was going to say "best of both worlds" on that post, looks like it's time to divulge that google hit - http://mastertouch327.com/2.html

I've talked to the owner and he has some technical information about these pipes coming my way. Everything used is SS including the internal baffling which is a perforated SS cone design of some sort, tunable for sound. I'll share the details when I get them, but I do like the ceramic coated inner pipe and the "coolshield" concept. Facing reality, my wife will be with me some of the time - and with her short legs, pipe contact is inevitable. She did "ok" the JBL build, I figure that's the least I can do (not that I'm into burnt calves either - sorry Jay Leno, that's one "badge of honor" I can live without  ).

MASTERTOUCH custom builds to your specs and they are performance conscious. You will also note that these pipes are not insanely priced like FireFly's (and without coolshield), so we'll see. In my opinion, that would be a pretty nice marriage with SS ceramic coated headers if his design holds up. (I will email you .pdf files of what he sends me).

One last question, if I were to go with SS ceramic coated headers - would just an outside coat be sufficient? Thinking risk mitigation in case there is some truth to Lelchook's comment re: internal hot spots the coating burns off and rust begins to generate.

Thanks for your assistance Richard, as always - much appreciated!

|

01-11-2011, 07:16 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 1999

Location: Fallbrook, CA USA,

CA

Cobra Make, Engine: Porsche 928 S4

Posts: 739

|

|

Not Ranked

Not Ranked

Machiavelli.

The stainless being stainless, (depending on the alloy) would not rust on the inside.

Therefore you could certainly just coat the outside.

The side-pipe design with the dead air space should work fairly well as the thermal conductivity of Air is 0.024 k - (W/mK). However where the outer skin is welded to the inner tube you are going to get significant heat transfer.

In other words hot spots at those locations.

|

01-11-2011, 08:20 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Richard,

I should elaborate on my last post a little -

With regard to the headers only, will just an outside coat be sufficient to alleviate the heat soak concern? I know that typically when you get your headers coated, it's an inside and outside job.

For the side pipes, yes - the inner tube to outer skin would be the thermal conduction path, no doubt why they say Yes, it does get warm, there is no way around that ... But if I were to guess why his design works, I would think because the whole outer skin is one large heat sink relative to the weld area conduction path. Looking forward to seeing the technical details.

|

01-11-2011, 08:24 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 1999

Location: Fallbrook, CA USA,

CA

Cobra Make, Engine: Porsche 928 S4

Posts: 739

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Machiavelli

Richard,

With regard to the headers only, will just an outside coat be sufficient to alleviate the heat soak concern? I know that typically when you get your headers coated, it's an inside and outside job.

|

Yes that should take care of the heat soak issue. |

01-11-2011, 08:41 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Ok, thanks Richard.

|

01-19-2011, 08:36 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Eric (Rare Iron),

Your chambered flow-thru exhaust makes sense, specifically when dealing with the sound reflection aspect of your "stamped" outer muffler shell to block the leakage from the inner 3" (or 2.5") diameter inner tube. I have also looked at everything on your website, all pictures show a head-on view of this "stamped" muffler concept. Just curious, because sound radiates 360within any chamber, and the annoying higher frequencies like to bounce on metallic surfaces, do you also stamp the opposite sides of your "powersticks" (not visible in the photos)? If not, why not? From where I sit, as long as you maintain that inner 3" (or 2.5") diameter clean flow-thru path, you have double the capacity to block those unwanted higher frequencies by stamping both sides? (Maybe they need to be staggered in some way, but you get the idea)

|

01-22-2011, 07:17 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

you were looking at fitting headers, this system might be helpful, posted by silverback on an earlier thread.

http://www.icengineworks.com/icewmain.htm |

01-22-2011, 09:29 AM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

vector1, certainly one way to go although not as user friendly as the PVC Mock-Up Kit offered by these other guys http://stainless.eclipticcms.com/customheaders

What I'm looking into now is corrective measures for a "too short" primary pipe length. What! No, I don't have that problem - just turning over more rocks. I think I can safely say "exhaust system engineering" is a lot like RF - freak'in BLACK MAGIC. Well, I'm an RF guy and I see some interesting parallels with exhaust systems and RF signal paths. (Yes Richard, I'm thinking WAY outside the box now). Being the savvy EE that I am, on more than one occasion electronic packaging has introduced unwanted VSWR to RF circuits (impedance mismatch - components in too close proximity to each other). In those instances, by screwing around with the circuit path downstream you can sometimes tune out the VSWR mismatch and get the throughput you want. So I'm looking at what corrective measures are out there with 4-1 collector designs, muffler lengths/diameters, and even primary ID tweaking to bring that mismatched exhaust system back in. Hey, it's all fun.

Looking forward to ...

RH lesson #318 - "Thinking outside the box, more often a poison than a remedy"

|

01-22-2011, 10:57 AM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Oh yeah, and this other thing that's bothering me - that rear header tight bend right out of the gate, can you say restrictive? vector1 agrees with me too!

Why don't you guys mod that inner panel next to the footwell to buy some needed space?

Anyone ever look at all that room these JBL's have in front of the motor? Damn, almost looks like you could start those headers off looking like a GT40 setup, then wrap 'em under to a collector behind the front wheel? Wow, get your optimum primary length and a clean single pipe exit to boot! (This one is a real stretch, someone slap me upside the head!)

Ok, I'm done now lol. |

01-22-2011, 12:31 PM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

i was just going to comment on the tight bend out the back exhaust port, but see you have already done that. the length of the primaries is the least important from what i understand.

|

01-22-2011, 02:30 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Cobra Make, Engine:

Posts: 80

|

|

Not Ranked

Not Ranked

Ok, but given no constraints with space - what would be the optimum length of the entire exhaust system be (header to tailpipe exit)?

Pretend the motor is on an engine mount, no car. If I cherry pick from your post #20 -

Single Primary Pipe (427, 3500-6000 RPM)

Length = 39.4" (highly recommended, best torque curve). My comment, but also note min RPM starts at 3500 so this is sort of a peaky setup.

From Collector Merge to Tailpipe Exit

Length = 43.0" (more bottom-end Torque). I selected this to counter some of that Primary Pipe peakiness above.

"Hypothetical Optimum" System Length = (39.4" + 43.0") = 82.4"

The assumption I am making is that your primary pipe length is determined by the distance from your exhaust port flange right to the actual 4-1 merge inside the collector (and obviously that all your headers are the same length).

Is the above a valid calculation knowing I fall within the pipe ID ranges in your post #20?

|

01-22-2011, 04:23 PM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

i would say yes, the program compensates for the exhaust port length using the valve face to mating surface, so the measurement of the primary pipe is face of the exhaust flange to the exit at the merge collector. in your case 3.2 was used for the exhaust port, all measurements would be centerline.

keep in mind this is a 427 with likely similiar specs as your engine, your cam & a few other things might move things slightly.

Last edited by vector1; 01-22-2011 at 04:26 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:19 AM.

Links monetized by VigLink

|