Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

38Likes 38Likes

12-23-2020, 02:54 AM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,130

|

|

Not Ranked

Not Ranked

stroked small blocks in the race cars?

stroked small blocks in the race cars?

It seems I have run across a reference that Ol' Shell had some strokers running at about 325ci displacement, for racing, but I did a search here and came up blank. Do any of you historians know of info on the FIA or USRRC cars that had bigger small blocks than 289ci in the early days? Perhaps it was later in the Mustangs?

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

12-23-2020, 07:05 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

Ford created an experimental race engine and some small number were used in Ford backed cars but I never heard of one in a Cobra. Maybe? If a Cobra got one it would have moved it out of a production class and into a modified or experimental class.

One of The Shelby American Automobile Club publications indicates that the Gurney-Ford Lotus 19B used one. I met a man with one for sale long ago. He claimed he obtained it with a broken connecting rod as scrap from Shelby American. He told me that neither Shelby nor Holman-Moody works could get him repair parts. He claimed he had to find a Ford engineer with enough connections inside Ford to round up what was required. He used the engine in a drag racer once it was repaired. The only other one I have come across was with a basket case GT40 in the 1980s. The car’s buyer was hunting parts so he could get that engine operable again.

There is a question as to what their displacement was. Ford company memos say at different times 323 and 325. Period casual references suggest that it was really more like 327 but that size call out would get confused with the Chevy street engines.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

Last edited by Dan Case; 12-23-2020 at 07:08 AM..

|

12-23-2020, 07:50 AM

|

|

CC Member

|

|

|

Join Date: Jan 2018

Location: Lafayette,

IN

Cobra Make, Engine: Looking to buy

Posts: 1,295

|

|

Not Ranked

Not Ranked

I read an article which quoted Gurney as saying the bottom end of the cobra racing motors was completely stock . I always wondered if that was true or if it might have been what he was told?

__________________

Cobra loving, autocrossing Grandpa Architect.

|

12-23-2020, 08:37 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by t walgamuth

I read an article which quoted Gurney as saying the bottom end of the cobra racing motors was completely stock . I always wondered if that was true or if it might have been what he was told?

|

Very little was done to short block assemblies by Shelby American at the way through the 1967 Mustang Group II season.

1963 team Cobra short block assemblies were almost stock except for oil pump pickup bracing that Ford developed in 1961, a shim behind the oil pump internal relief spring, larger capacity oil pans, better balancing than Ford’s assembly line, and safety wiring of some critical fasteners. Even with the upper end modifications of ported cylinder heads and 4-2V induction system the stock cam shafts Ford installed were used. XHP-260 engines had weird camshafts. HP260 engines had a cam shaft that was the parent of the HP289 stock cam shaft. The stock HP289 cam shaft was used and sold as a racing part for years.

By 1965 Ford’s Don Sullivan created a family of cam shafts for Shelby to use. The final version was sold by Ford for years as a race part. Engle made custom ground cam shafts for Shelby American in that time frame also. By 1965 Shelby American was fond of drilling, tapping, and plugging the steam holes in cylinder blocks. They were also fond of having the contractors doing cylinder head work weld up the “banana” steam holes in cylinder heads. The engines for 1965 MUSTANG GT350s had the press in core plugs at one end of the lifter oil galleries removed and sealed with threaded plugs. Crankshaft journals had oil grooves cut into them.

1965-1967 some of the teams C6FE-A racing cylinder heads got rings cut into their decks for metal combustion chamber sealing rings and some did not. Set five was so modified and we have that set in our red car currently.

1967 was the last year for 289s and the pistons Ford included in the Group II crate engines were stock HP289 pistons with valve reliefs enlarged for using C6FE-A cylinder head assemblies.

On the Ford front there were all kinds of prototype, experimental and limited manufacture small block engines. The aluminum 255 INDY push rod engine didn’t work out too well. One was very briefly tested in a Cobra before it had a failure. The Single Over Head Cam HP289 didn’t make it past testing (Rumor says that exhaust flow was the problem because Ford wanted to use stock HP289 cast iron exhaust manifolds. ). There were 1965 and 1966 versions of steel crankshafts and four bolt main cylinder blocks.

All that said, building a duplicate of a 1963-65 Shelby team race engine long block assembly is very easy, just start with a real nice assembly line HP289. Most of what was described above was reported with pictures in most of the automotive magazines in the USA and some abroad in period. The induction systems (many versions) are what the typical weekend warrior would have not been able to afford or maybe just rationalize. In 1963 the 4-2V Cobra induction kit had a suggested retail price of $1,230.70. There were some new cars one could buy in that price range. In period it was predominately extra wealthy owners that had “Webers” on their racing Cobra. The not so rich racers used everything from the stock 4V iron intakes to whatever came out each new season in the aftermarket. The original owner / racer of a new 1964 Cobra had a circa 1967 picture on the wall of his car with two holes in the bonnet and air cleaners poking out of those holes. He raced in SCCA with a very tall 2-4V cross ram induction system. Name a brand and style of “racing” intake for one or more carburetors sold between 1965 and let’s say 1972 and at one time or another and I probably saw one on a Cobra except for a Man-A-Fre® 4-2V.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

Last edited by Dan Case; 12-23-2020 at 10:06 AM..

Reason: spelling

|

12-23-2020, 10:37 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

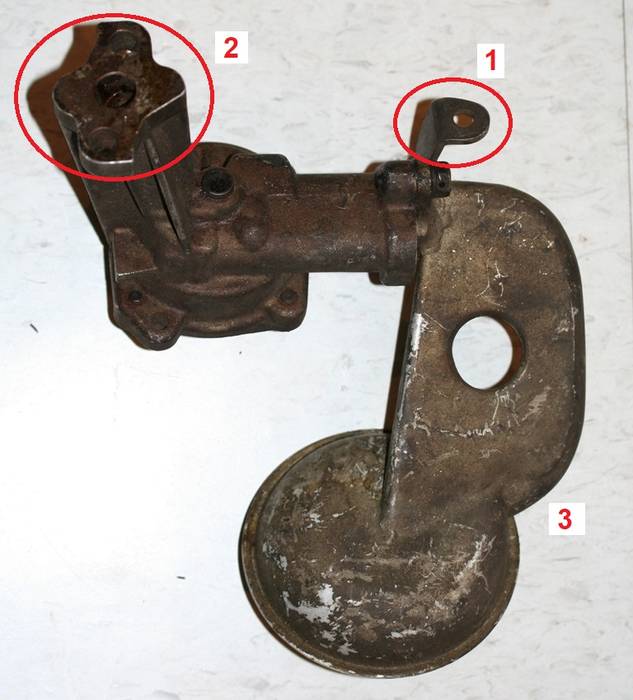

One of the most significant modifications to the short block assembly was the addition of support structures for the oil pumps. The XHP-260 engines from Ford had this set of modifications and Shelby used them with very slight revisions from then on in small block engines.

Bracket marked 1: Added to tame vibration in the aluminum oil pump so that the pump mounting based marked 2 would not fatigue and snap off. A doubled ended main bearing stud from another Ford heavy duty application doing a similar job was used at the main bearing cap. In 1963˝ HP289 engines Shelby American reused the stock fasteners but added holes into their heads for safety wiring. Later they used aircraft drilled head fasteners.

Gusset marked 3: Added to tame the vibration in the oil pump pickup. The modified part was cadmium plated. WARNING. 1962 pump pickups and 1963 onward parts are for different depth oil pans. Oil pans got shallower starting in 1963. If you put a 1963 or later Ford pan over a 1962 pickup there is little to no space for oil to get into the inlet and that is without somebody jacking the engine up by the pan and pressing it up some more. XHP-260 engines had 1962 length modified pickups. All the HP289 engines had 1963 onward length pickups.

The other significant oiling system change was the addition of a shim behind the internal relief spring of the stock pump to increase cold relief pressure. (These engines have little or no oil filtering until the oil warms and its viscosity goes down. On cold starts cold viscous oil does not pass through the element well. To prevent damage the bypass spring opens and lets oil go around the filter. Putting a shim behind the relief spring increases that cold start relief point.)

A set of correspondences between Shelby American and a customer surfaced that illustrates the issue of breaking the oil pump off its mount. A customer wanted to race his new Cobra but did not want to pay for having Shelby American race prepare the engine. The oil pump broke away and the customer was upset. The response he got back was a pleasant ‘we told you so’. Remember these were stock cast aluminum assembly line Ford pumps. I never heard of any trouble if a Melling® cast iron pump was used later on.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

Last edited by Dan Case; 12-23-2020 at 10:45 AM..

Reason: add detail

|

12-23-2020, 10:55 AM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,130

|

|

Not Ranked

Not Ranked

Thanks, Dan! I figured you might have some info on the subject. As you mention it, I think I may have gotten the information from some racing history website that listed engine displacements... it seems that there was a Shelby backed car that was in that 323-325ci range you mentioned.

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

Last edited by PDUB; 12-23-2020 at 10:58 AM..

|

12-23-2020, 11:00 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PDUB

Thanks, Dan! I figured you might have some info on the subject. As you mention it, I think I may have gotten the information from some racing history website that listed engine displacements... it seems that there was a Shelby backed car that was in that 323-325 range you mentioned.

|

You are welcome. That first one I came across being used in a drag racer was for sale at the time. The seller was dropping to a different class. He wanted more for the engine than we paid for our black Cobra. He also had a new set of Ford experimental bearings and rings to go along with the engine. I declined.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

|

12-23-2020, 11:05 AM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,130

|

|

Not Ranked

Not Ranked

Would they have been welding cranks to get to 325ci, at that time, or did they have some special casting runs?

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

12-23-2020, 11:13 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PDUB

Would they have been welding cranks to get to 325ci, at that time, or did they have some special casting runs?

|

I have no idea but Ford engineering could create just about anything and often did. Ever hear about the Mirage 351W created for GT40s in 1967. Really weird.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

Last edited by Dan Case; 12-23-2020 at 11:17 AM..

|

12-23-2020, 11:27 AM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,130

|

|

Not Ranked

Not Ranked

Was that the aluminum block version?

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

12-23-2020, 11:47 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PDUB

Was that the aluminum block version?

|

Mirage 351? The only ones I have seen in pictures were iron block and heads. Pieces of those engine circulate around in the GT40 world.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

|

12-23-2020, 12:00 PM

|

|

CC Member

|

|

|

Join Date: Jan 2018

Location: Lafayette,

IN

Cobra Make, Engine: Looking to buy

Posts: 1,295

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Dan Case

Very little was done to short block assemblies by Shelby American at the way through the 1967 Mustang Group II season.

1963 team Cobra short block assemblies were almost stock except for oil pump pickup bracing that Ford developed in 1961, a shim behind the oil pump internal relief spring, larger capacity oil pans, better balancing than Ford’s assembly line, and safety wiring of some critical fasteners. Even with the upper end modifications of ported cylinder heads and 4-2V induction system the stock cam shafts Ford installed were used. XHP-260 engines had weird camshafts. HP260 engines had a cam shaft that was the parent of the HP289 stock cam shaft. The stock HP289 cam shaft was used and sold as a racing part for years.

By 1965 Ford’s Don Sullivan created a family of cam shafts for Shelby to use. The final version was sold by Ford for years as a race part. Engle made custom ground cam shafts for Shelby American in that time frame also. By 1965 Shelby American was fond of drilling, tapping, and plugging the steam holes in cylinder blocks. They were also fond of having the contractors doing cylinder head work weld up the “banana” steam holes in cylinder heads. The engines for 1965 MUSTANG GT350s had the press in core plugs at one end of the lifter oil galleries removed and sealed with threaded plugs. Crankshaft journals had oil grooves cut into them.

1965-1967 some of the teams C6FE-A racing cylinder heads got rings cut into their decks for metal combustion chamber sealing rings and some did not. Set five was so modified and we have that set in our red car currently.

1967 was the last year for 289s and the pistons Ford included in the Group II crate engines were stock HP289 pistons with valve reliefs enlarged for using C6FE-A cylinder head assemblies.

On the Ford front there were all kinds of prototype, experimental and limited manufacture small block engines. The aluminum 255 INDY push rod engine didn’t work out too well. One was very briefly tested in a Cobra before it had a failure. The Single Over Head Cam HP289 didn’t make it past testing (Rumor says that exhaust flow was the problem because Ford wanted to use stock HP289 cast iron exhaust manifolds. ). There were 1965 and 1966 versions of steel crankshafts and four bolt main cylinder blocks.

All that said, building a duplicate of a 1963-65 Shelby team race engine long block assembly is very easy, just start with a real nice assembly line HP289. Most of what was described above was reported with pictures in most of the automotive magazines in the USA and some abroad in period. The induction systems (many versions) are what the typical weekend warrior would have not been able to afford or maybe just rationalize. In 1963 the 4-2V Cobra induction kit had a suggested retail price of $1,230.70. There were some new cars one could buy in that price range. In period it was predominately extra wealthy owners that had “Webers” on their racing Cobra. The not so rich racers used everything from the stock 4V iron intakes to whatever came out each new season in the aftermarket. The original owner / racer of a new 1964 Cobra had a circa 1967 picture on the wall of his car with two holes in the bonnet and air cleaners poking out of those holes. He raced in SCCA with a very tall 2-4V cross ram induction system. Name a brand and style of “racing” intake for one or more carburetors sold between 1965 and let’s say 1972 and at one time or another and I probably saw one on a Cobra except for a Man-A-Fre® 4-2V. |

Thanks Dan! A very thorough listing of modifications it appears. Sounds like they did use ford parts but with critical modifications to increase durability and performance.

Man a fre....I remember reading the small ads for these back in the day. Were they any good?

__________________

Cobra loving, autocrossing Grandpa Architect.

|

12-23-2020, 12:30 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Considering that they were able to get 450 Hp out of the 289, and they were doing this by porting the cast iron heads, going to a longer stroke 327ish engine would likely not make any more power. It would likely just make the same Hp at a lower rpm. Since the 289 was standing up well to the rpms they were turning them, there was no need to do this and the rules of the day may have limited them to the factory displacement. Had there been a need for more displacement, those engines would be everywhere. A research item here or there makes sense. You have to always be looking for an advantage.

This is just an observation and a personal opinion. I could be wrong and have been several times.

|

12-23-2020, 12:59 PM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,033

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by t walgamuth

Thanks Dan!

Man a fre....I remember reading the small ads for these back in the day. Were they any good?

|

You are welcome. I have no idea if any of the Man-a-Fre® intakes were effective. The one for a 260/289 Ford engines is pretty odd looking.

Maybe this link will work.

https://www.jalopyjournal.com/forum/...intake.989833/

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

|

12-23-2020, 01:47 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,130

|

|

Not Ranked

Not Ranked

Yep, that is an odd bird!!! You would think that if they were awesome they would have become a household name...

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

12-23-2020, 02:42 PM

|

|

CC Member

|

|

|

Join Date: Jan 2018

Location: Lafayette,

IN

Cobra Make, Engine: Looking to buy

Posts: 1,295

|

|

Not Ranked

Not Ranked

I think they were used by some hot rodders. ....so the early cobra guys and the hot rodders all knew each other and may have dated the same gals.') I imagine it was a cheaper alternative to four webers.

__________________

Cobra loving, autocrossing Grandpa Architect.

|

12-23-2020, 04:58 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

I suspect with the carburetors directly above the intake port and very limited space for intake runner length, these manifolds would have ended up being deficient in low speed torque and possibly / probably providing a high peak hp number good for bragging purposes but not much else.

For the most part, extremely short runner intake manifolds disappeared quickly in the sixties as the benefits of ram tuning became more well known.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 12-23-2020 at 05:23 PM..

Reason: Spelling & Grammar

|

12-23-2020, 06:59 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,130

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by olddog

Considering that they were able to get 450 Hp out of the 289, and they were doing this by porting the cast iron heads, going to a longer stroke 327ish engine would likely not make any more power. It would likely just make the same Hp at a lower rpm. Since the 289 was standing up well to the rpms they were turning them, there was no need to do this and the rules of the day may have limited them to the factory displacement. Had there been a need for more displacement, those engines would be everywhere. A research item here or there makes sense. You have to always be looking for an advantage.

This is just an observation and a personal opinion. I could be wrong and have been several times.

|

While modern technology makes it available now, 450Hp is more than I had heard before from a 289 back in the day. It seems I recall Brent doing one in that range, recently. I thought it was more in the 340-350Hp range, which I've heard said by those in the know to be optimistic. Isn't the 289 head a limiting factor in getting to that power level - even with aggressive porting? That would be awesome, if it was not at 7000rpm. Maybe Brent can chime in here...

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

12-23-2020, 07:12 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

I thought the 289 inch engines with Webers were in the 380 / 390 hp area, no?

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

12-23-2020, 07:17 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Brent has been able to pull about 450 HP from a 289. Mine with aftermarket iron heads was able to pull 424 HP at 6500 rpms, and still had 420 HP at 7,000. I have heard of one engine builder claiming 585 HP at 8,000 rpm in a 289 that was using iron heads to be vintage race legal. Not quite sure what he is doing to obtain those numbers. One thing that he is doing is using a Dart iron block. The engine builder that I brought mine too for a refreshing was amazed that I was getting the power that I was with a block from 1965. His opinion was that I was exceeding the strength of the block and that sooner or later it would break.

I never heard of the original 289 cobras obtaining HP in the 400 range, as Ed said it was more in the 375-390 HP range. I am going to be switching to a Dart iron block to ensure engine longevity, it is better suited to road racing applications given the more stout design, better oiling and cooling, and the casting is new, as opposed to 55 years old. The downside is that the Dart block is about 35 lbs heavier than the original block.

Jim

__________________

Last edited by 1795; 12-23-2020 at 07:29 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:15 AM.

Links monetized by VigLink

|