02-10-2007, 06:05 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

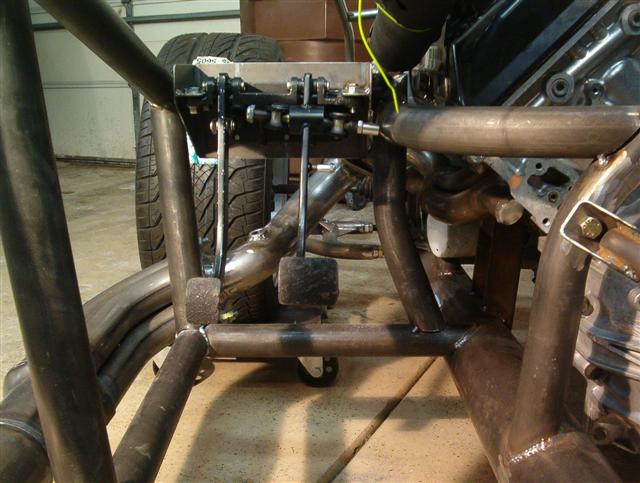

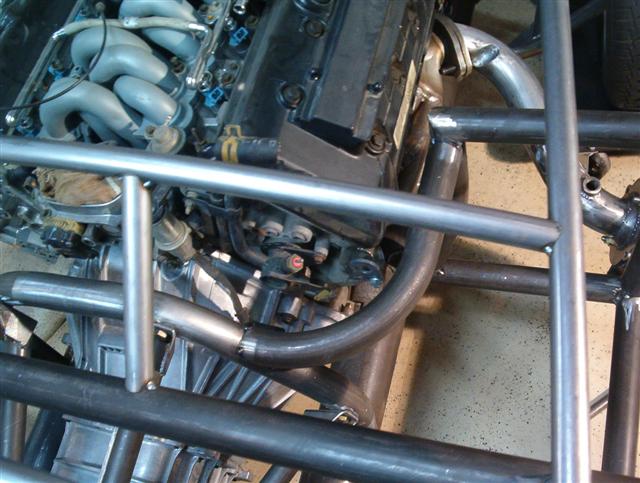

Room for fancy footwork (I think I can dance)

Room for fancy footwork (I think I can dance)

Well, running out of room quickly but I think this will have to do. Put the pedal assembly and foot box frames in the car, tried to make as much room as possible. This engine is so wide, my feet will be within 2"of the exhaust manifold  . Now I still have to come up with a throttle pedal (cable type). Thats where all of you come in, show me your pics, need ideas to steal.  Still searching for radiator and windshield.

As usual more pics in gallery:  Patrick

Last edited by fasterpatrick; 12-03-2007 at 08:27 PM..

|