Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2026

January 2026

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

07-15-2008, 01:03 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Cobra Make, Engine:

Posts: 9

|

|

Not Ranked

Not Ranked

Leak at bell housing - any ideas?

Leak at bell housing - any ideas?

My Backdraft Cobra has a Ford Racing 347 with a Tremec 5 speed, and I recently noticed a slight drip of what appears to be coolant (?) down the outside center of the inspection plate on the bell housing.

After some cursory inspection, it is not obvious where the source of the leak is coming from. It doesn't appear to be coming from within the bell housing, but outside of it somewhere around the top of the oil pan. I checked the oil, and there doesn't seem to be any water in it.

Anyone experience a similar issue? Any ideas? Thanks in advance.

Sam

BDR #???

Last edited by shatoum; 07-15-2008 at 01:04 PM..

Reason: typos

|

-

Advertising

07-15-2008, 01:26 PM

|

|

CC Member

|

|

|

Join Date: Nov 2002

Cobra Make, Engine: Midstates,SBF 357

Posts: 418

|

|

Not Ranked

Not Ranked

You may have an intake manifold leak. Could be a head bolt?????

|

07-15-2008, 01:28 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,618

|

|

Not Ranked

Not Ranked

Maybe check that your intake manifold is seated completely. I fought a drip in the front for almost 4 months before I finally decided to re-torque my intake bolts. That stopped the drip and I never did find exactly where is was coming from. But I have a feeling that the front seal across there in that corner wasn't seated and the bold had backed off just a tiny bit. After torquing them I never found another drip.

Ron

|

07-15-2008, 02:21 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Cobra Make, Engine:

Posts: 9

|

|

Not Ranked

Not Ranked

Thanks for the feedback. If the intake bolts need to be re-torqued, is there a sequence to go about doing this? And how do I know what the torque setting should be? Pardon my ignorance, but I couldn't find this information on the Ford Racing site.

|

07-15-2008, 02:32 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 2006

Location: Santa Cruz,

CA

Cobra Make, Engine: SPF 2613 Titanium w/Black, Roush 402SR

Posts: 4,098

|

|

Not Ranked

Not Ranked

Sam - You might want to buy an inexpensive fluorescent leak detection kit. I bought this one from Summit, but I think that Napa Auto sells something simlar at lower price.

http://store.summitracing.com/partde...5&autoview=sku

It comes with dye for oil and water and is pretty effective in pinpointing leaks.

__________________

Doug

No stop signs, speed limit - Nobody's gonna slow me down - Like a wheel, gonna spin it

|

07-15-2008, 02:37 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

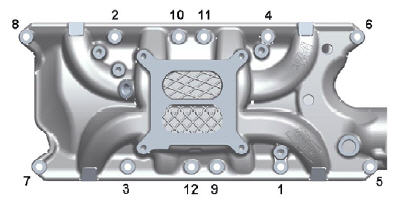

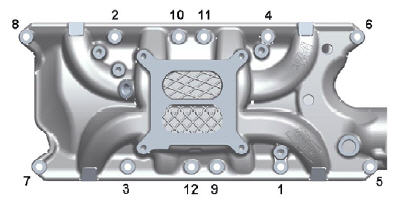

Try re-torquing your IM with this as a pattern and 25 ft/lbs and see if you get lucky.

|

07-16-2008, 11:12 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Cobra Make, Engine:

Posts: 9

|

|

Not Ranked

Not Ranked

Thanks all for the feedback. Looks like I have a place to start. I'll reply with what I find.

|

07-18-2008, 06:09 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,618

|

|

Not Ranked

Not Ranked

GTB is correct about the leak detector. I have one that I got at NAPA and it works very well. I just add the dye to the oil or tranny and then drive it and after it sets the light will show any leaks very well.

Ron |

07-18-2008, 08:02 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Cobra Make, Engine:

Posts: 9

|

|

Not Ranked

Not Ranked

UPDATE: So I remove the air filter, and then I see coolant along the intake manifold gasket around the #1 bolt near the front. I check the #1 manifold bolt, and it is loose very loose. Break-out the torque wrench, and start tightening per the sequence. Started with 10 ft/lbs, everything OK. Then went to 15 ft/lbs, and the #1 bolt pops (other bolts were OK at 15 by the way). Luckily I was able to remove the broken #1 bolt completely (thank you GOD!!). So now a couple of questions:

- What should the torque setting be on these bolts? I was going to work up to 25 ft/lbs, but based on what happend, not sure anymore.. The manifold is a single-pane Victor Jr. (Ford Racing #M-9424-D302), and the heads are Edelbrock Victor Jr. Really having a hard-time confirming the torque values for these..

- Should I just replace the broken bolt, or replace the entire bolt set?

- What does this do to the torquing sequence? Do I need to loosen all and start all over?

- Or do I need to start from scratch and replace the gasket?

Suggestions??

|

07-18-2008, 09:07 AM

|

|

CC Member

|

|

|

Join Date: Nov 2002

Cobra Make, Engine: Midstates,SBF 357

Posts: 418

|

|

Not Ranked

Not Ranked

Chances are the bolt that broke was over tightened at some time. I would replace them all based upon the one breaking. There may be more that are stretched to their limit.

|

07-18-2008, 11:24 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by sharpe 1

I would replace them all based upon the one breaking.

|

Replace them all with quality bolts. For you to snap one off at 15 ft/lbs means the bolt is either defective or had really been torqued down hard by someone else. Either way you want to swap out that set.

Edit -- here are the PDF installation instructions for 2 Victor IMs, Ford and Chevy. Ford calling for 16-18 ft/lbs and Chevy calling for 25 ft/lbs. FWIW, I have my Blue Thunder on the FE torqued to 30 ft/lbs.

http://www.edelbrock.com/automotive_...7000/77169.pdf

http://www.edelbrock.com/automotive_.../2000/2978.pdf

Last edited by patrickt; 07-18-2008 at 11:34 AM..

|

07-18-2008, 07:46 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Cobra Make, Engine:

Posts: 9

|

|

Not Ranked

Not Ranked

Thanks for the feedback. Went out to the local spped shop and purchased a set of ARP bolts, and ready to change them. Now I am worried about an internal leak. Without replacing the gasket, is there any way to tell if there is coolant getting into the piston chamber? I thought if I checked the oil, and it was free of water, then I was in the clear. Is that true? Just hate to go through the trouble of changing the gasket if it is not necessary. Thanks. |

07-18-2008, 08:10 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by shatoum

... is there any way to tell if there is coolant getting into the piston chamber?

|

After you retorque your bolts, pressurize your coolant system to about 12 pounds and see if it will hold that for 15 minutes -- if it holds, then that's a good sign your gasket is tight. You can borrow a coolant pressure tester at Autozone (or your local equivalent). |

07-21-2008, 08:58 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Cobra Make, Engine:

Posts: 9

|

|

Not Ranked

Not Ranked

Looks like my coolant leak issue is mostly resolved (with your help of course - THANKS!). The coolant was running down the top of the oil pan, all the way back to the bell-housing.The leak(s) were from:

(1) the intake manifold - replacing the bolts with ARP bolts that dont stretch, and torquing them to spec fixed that

(2) the water pump gasket - tightening these bolts fixed that (I think)

Now I am wondering if I should replace the water pump bolts with a quality set. Any opinions? And is there a torque setting for these, or just "snug" is enough? |

07-21-2008, 11:32 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

If it's not leaking then I would leave it alone.

|

07-21-2008, 11:49 AM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Millbrook,

NY

Cobra Make, Engine: ERA 758 KC Pond 482

Posts: 391

|

|

Not Ranked

Not Ranked

By the way, ARP and every other bolt stretches as it is supposed to in order to achieve proper clamp load in a threaded fastener joint. If you go too far, you exceed the elastic limits of the fastener and you approach the yield point. Most modern cars use head bolts that are into the yield curve of the bolt so that is why they are considered "one time use" only. It requires a sophisticated fastening tool to accurately know when you are approaching the yield point (they detect change in slope of the torque vs degrees of rotation curve during the tightening cycle).

Some very good info here:

http://www.boltscience.com/pages/tighten.htm |

07-21-2008, 02:59 PM

|

|

CC Member

|

|

|

Join Date: Nov 2002

Cobra Make, Engine: Midstates,SBF 357

Posts: 418

|

|

Not Ranked

Not Ranked

I would find the torque for the water pump bolts and torque them properly.All bolts on an engine have a torque spec. .

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 02:25 PM.

|

Linear Mode

Linear Mode