Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2026

January 2026

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

12Likes 12Likes

01-01-2021, 01:16 PM

|

|

CC Member

|

|

|

Join Date: Sep 2001

Location: Danville,

CA

Cobra Make, Engine: CSX 6079 482CI CSX cross ram

Posts: 1,354

|

|

Not Ranked

Not Ranked

twin disk clutch

twin disk clutch

on my last Cobra (ERA 626) I had a single disk clutch with a hydraulic slave cylinder. It worked great with normal effort to push in the clutch.

just built a new CSX car and I used a twin disk clutch with a hydraulic slave cylinder set up from Kirkham, very nice set up. But I notice that is harder to depress the clutch pedal. I have not driven the car yet and am wondering does the clutch "break in " and get easier to push in? my wife will kill me ... I can deal with it but she wont...

|

-

Advertising

01-01-2021, 02:08 PM

|

|

CC Member

|

|

|

Join Date: Jan 2018

Location: Lafayette,

IN

Cobra Make, Engine: Looking to buy

Posts: 1,295

|

|

Not Ranked

Not Ranked

The dual disc clutch I have in my Cobra is significantly more difficult to push than the single disc before....course the single disc was not up to the torque of my engine doing autocross starts.

__________________

Cobra loving, autocrossing Grandpa Architect.

|

01-01-2021, 03:14 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

That seems odd to me. The guys who have installed McLeod twin disc clutches in ERAs have commented about the light pedal pressure. The twin disc I had in my Shelby GT350 was feather light.

|

01-01-2021, 05:00 PM

|

|

Full Blown Member

|

|

|

Join Date: Sep 2008

Cobra Make, Engine: KMP 427 S/C, Twin Paxton 511 FE

Posts: 2,594

|

|

Not Ranked

Not Ranked

Can't say I noticed a differnce.

But when she's all warmed up, she GRABS.

__________________

rodneym

|

01-01-2021, 07:13 PM

|

|

CC Member

|

|

|

Join Date: Jan 2018

Location: Lafayette,

IN

Cobra Make, Engine: Looking to buy

Posts: 1,295

|

|

Not Ranked

Not Ranked

Mine is a McCloed.

__________________

Cobra loving, autocrossing Grandpa Architect.

|

01-01-2021, 08:04 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Unless you're going drag racing with really sticky tires, or you're going to repeatedly strap your car down to the chassis dyno so it can't break traction, I don't think it really matters on a mostly street driven car that only has 600 lbs on each rear wheel. My crappy Yokos break loose if I give it any sort of throttle, like maybe 200 ft/lbs or less of throttle. I think a cardboard driven disk and a pressure plate made of bobby pins would hold it all together and the tires just break loose when the torque gets cranking.  |

01-02-2021, 02:13 AM

|

|

CC Member/Contributor

|

|

|

Join Date: Sep 2016

Location: (Beautiful) Sequim,

WA

Cobra Make, Engine: Pacific Roadster, 347 cu.in. 5-speed

Posts: 2,018

|

|

Not Ranked

Not Ranked

As Patrickt, said for most street driving, I use my tires as the limiting factory. Easiest & Cheapest to change. Back in the Day, running for a championship, Even Auto-xing in stock class you used a set of tires just for that propose. To tell you how long ago that was the trick tires were (Yoko's 008 RS 2's  ). Just wondering Mike, is there a reason you went to a two disc set-up??? Cheers TommyRot. |

01-02-2021, 04:39 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA 626

on my last Cobra (ERA 626) I had a single disk clutch with a hydraulic slave cylinder. It worked great with normal effort to push in the clutch.

just built a new CSX car and I used a twin disk clutch with a hydraulic slave cylinder set up from Kirkham, very nice set up. But I notice that is harder to depress the clutch pedal. I have not driven the car yet and am wondering does the clutch "break in " and get easier to push in? my wife will kill me ... I can deal with it but she wont...

|

The number of clutch plates does not affect the feel at the pedal.

The pressure plate diaphragm spring, and then the throwout fork/hydraulic cylinder ratio, pedal ratio, determines the pedal effort.

Gary

__________________

Gary

Gold Certified Holden Technician

|

01-02-2021, 04:59 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

I would check the size of your master cylinder. A twin disc should not be hard to push.

|

01-02-2021, 06:12 AM

|

|

CC Member

|

|

|

Join Date: Jan 2018

Location: Lafayette,

IN

Cobra Make, Engine: Looking to buy

Posts: 1,295

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gaz64

The number of clutch plates does not affect the feel at the pedal.

The pressure plate diaphragm spring, and then the throwout fork/hydraulic cylinder ratio, pedal ratio, determines the pedal effort.

Gary

|

Yes, but a dual disc design will hold more power than a single disc for a given pedal pressure.

__________________

Cobra loving, autocrossing Grandpa Architect.

|

01-02-2021, 07:10 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,293

|

|

Not Ranked

Not Ranked

I had a Mcleod RXT dual disc in my 640hp C6 Z06 and it was a complete POS. It started slipping with 10K on the clock. It had minimal abuse too. There are much better choices out there.

__________________

Too many toys?? never!

|

01-02-2021, 07:13 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by undy

I had a Mcleod RXT dual disc in my 640hp C6 Z06 and it was a complete POS.

|

You should have gotten my cardboard/bobby-pin clutch from Centerforce. Works like a charm.  |

01-02-2021, 07:15 AM

|

|

CC Member

|

|

|

Join Date: Feb 2009

Posts: 1,696

|

|

Not Ranked

Not Ranked

I have a McLeod RXT in my Cobra and it is probably the nicest clutch I have ever had. The old clutch was a single disk rated for 700 rwhp, and you had to shift into neutral at every stop light just to save your leg from cramping. The pedal feel is awesome and pretty light. It also doesn't chatter like the old clutch had a tendency to do.

My buddy just installed one in his AMX for the same reason I did. He loves it also.

|

01-02-2021, 07:18 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,293

|

|

Not Ranked

Not Ranked

I've had even worse luck with Centerfarce. Advance auto remanufactured clutches hold better.

__________________

Too many toys?? never!

|

01-02-2021, 12:55 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gaz64

The number of clutch plates does not affect the feel at the pedal.

The pressure plate diaphragm spring, and then the throwout fork/hydraulic cylinder ratio, pedal ratio, determines the pedal effort.

Gary

|

What Gary said is spot on.

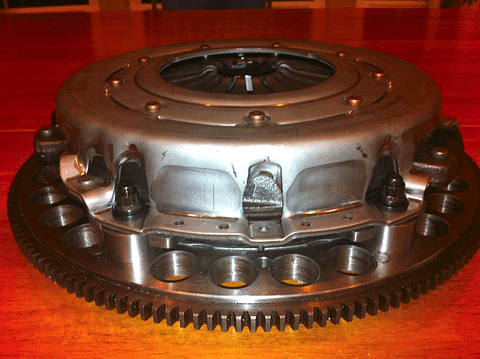

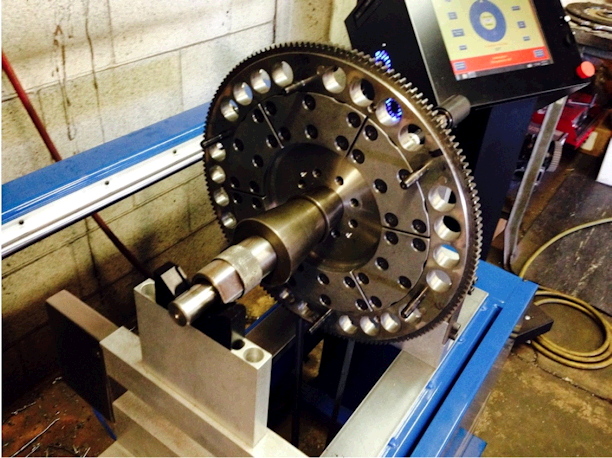

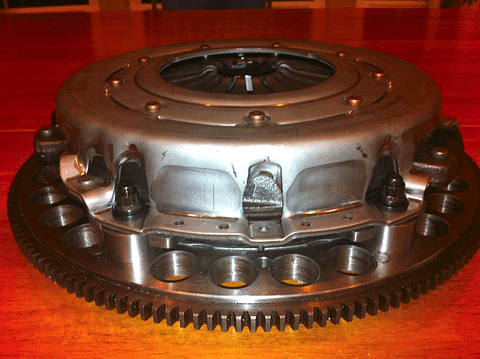

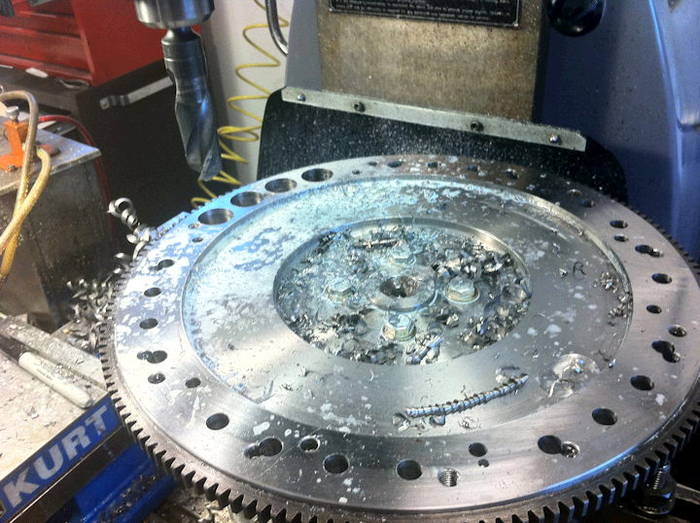

I made my own 10.5" dual disc clutch before McLeod had their RSX/RST versions commercially available. The clutch set up is particularly important if you want the car to drive properly and shift correctly. Here is a picture of my finished, assembled unit;

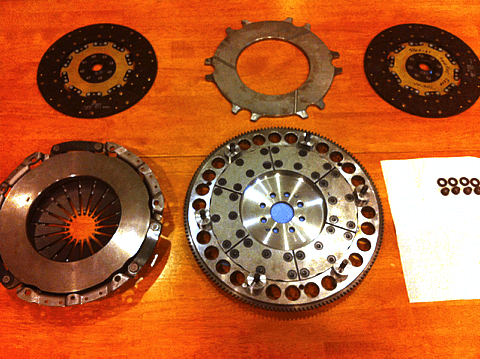

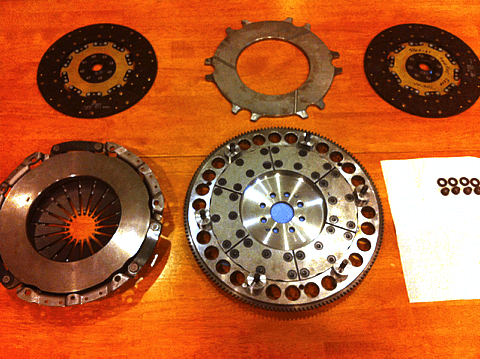

Here are pictures of the finished components, prior to assembly;

The pressure plate was a 10.5" Ford FRPP component that uses a high leverage diaphragm spring to provide a high clamping force at a low pedal pressure. Like Gary has already pointed out, you have complete control over how this feels by properly selecting the throwout fork/hydraulic cylinder ratio, pedal ratio. My pedal feels very light, very much like an OEM showroom stock vehicle's clutch.

The discs I used are organic McLeod solid hub discs for their older style dual disc clutches. McLeod uses a wavy spring called a Marcel spring between the friction material and the steel disc, friction material, mounting plate. The effect is a gradual compression of the wavy spring as the clutch applies until the friction material, marcel spring and disc substrate stack solid. The driving experience is a silky smooth engagement anyone can easily handle when driving it.

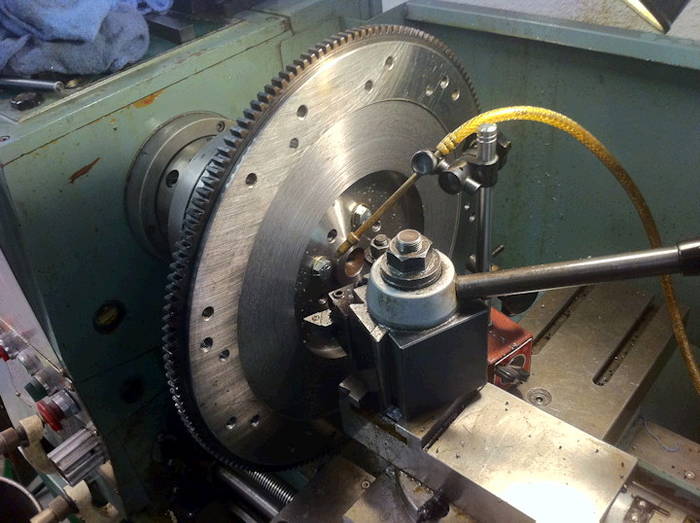

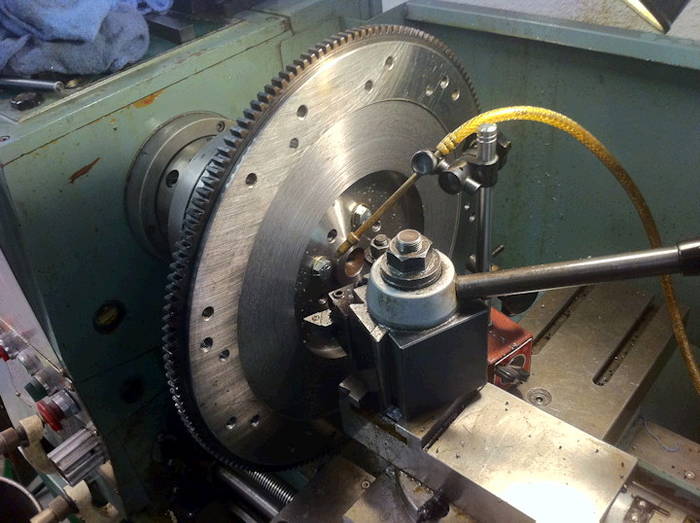

The floater was a Crower floater that I modified to work with the layout on my clutch build. The flywheel was a fabricated unit that I built to use replaceable Crower heat shields from their blown alcohol clutch designs. Here are a few pics of it as I cut the relief for the heat shields;

And then again later as I am drilling the holes around the circumference to remove rotating mass I did not want.

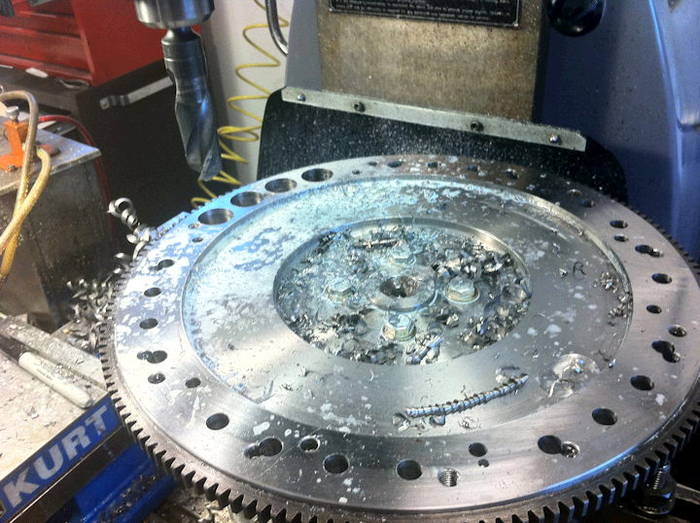

After the perimeter I go in to locate the attaching bolt holes for Crower's heat shields;

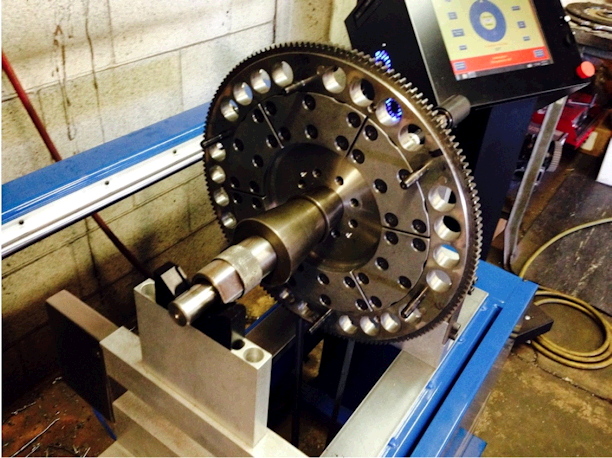

This is the finished wheel less the heat shields;

And of course this is what it looks like in final form with the heatshilds attached;

Once I had completed the flywheel, I took it over to the balancer to see how much imbalance I had added to the assembly.

I was surprised to find the wheel was within 1 gram of a perfect balance! Who said blind squirrels can't find acorns?

BTW the cost for the entire shebang was somewhere around $600 or $650 when I did it about 10 years ago.

Driving it, it has a light clutch pedal, smooth engagement and just an all around pleasant driving experience.

If you buy a performance equivalent and you do not pay attention to the clearance stack up in the clutch pack you will not have a happy experience. If you do and you do not screw up your clutch linkage you will be very pleasantly surprised at how light the clutch pedal feel is and how predictable the engagement is.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 01-02-2021 at 01:40 PM..

Reason: Spelling & Grammar

|

01-02-2021, 02:13 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by undy

I've had even worse luck with Centerfarce. Advance auto remanufactured clutches hold better.  |

It's because they *are* Advance Auto clutches. The pressure plate is a Luk brand, with counterweights added. The disc is nothing special. Of all the manufacturers, I rarely get a call about an issue with RAM or McLeod. I've had all kinds of emails/calls about Centerforce.

As for the RXT, that's been the only streetable clutch that has held in one of my customer's cars. It's an old Galaxie wagon with a 390. Launches at 6000 on slicks, shifts at 7000. Weighs almost 5000 lbs.

The RST has had issues with higher horsepower applications from what I've seen, but the RXT has been bulletproof on my stuff so far. |

01-02-2021, 03:13 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by eschaider

What Gary said is spot on.

I made my own 10.5" dual disc clutch before McLeod had their RSX/RST versions commercially available.

|

Dang, that's some serious fabrication. Especially when it's spinning at 7000 RPM.  |

01-02-2021, 04:00 PM

|

|

CC Member

|

|

|

Join Date: Feb 2014

Location: White City,

SK

Cobra Make, Engine: West Coast, 460 CID

Posts: 2,916

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

I would check the size of your master cylinder. A twin disc should not be hard to push.

|

Agreed, a smaller MC may be the fix, though pedal travel will be longer.

__________________

Brian

|

01-02-2021, 07:19 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,741

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Dang, that's some serious fabrication. Especially when it's spinning at 7000 RPM.  |

I know what you mean, Patrick. It is more than a little sobering. That said, the reality of it all did not sink in for me until well after the job was done, in the car and I had spun it up there a couple of times. Even had I bought an aftermarket solution I would have still used the Lakewood can. It can do a great deal to blunt the impact of any clutch / flywheel explosion, home built or otherwise.

I also spent a lot of effort to carefully machine all the pieces and always used high grade / high quality virgin billet steel. As I finished each piece, I worked hard to remove any potential stress risers I could find that were left behind from from the machining process.

Overall I feel as comfortable with it as if I had bought an SFI certified aftermarket piece. At the time there were no aftermarket dual disc setups available for the engine so it was the old hot rodding approach of make it your self if you can't buy one.

What I did with fabricating the clutch is not such a big deal. What Morris did with his car is a BIG deal.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 01-02-2021 at 07:24 PM..

Reason: Spelling & Grammar

|

01-02-2021, 07:24 PM

|

|

CC Member

|

|

|

Join Date: Sep 2001

Location: Danville,

CA

Cobra Make, Engine: CSX 6079 482CI CSX cross ram

Posts: 1,354

|

|

Not Ranked

Not Ranked

my master cylinder is .750 with a 7/8" slave. I am considering going with a .625 master, this will improve the clutch effort...

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 11:13 AM.

|

12Likes

12Likes

). Just wondering Mike, is there a reason you went to a two disc set-up??? Cheers TommyRot.

). Just wondering Mike, is there a reason you went to a two disc set-up??? Cheers TommyRot.

Linear Mode

Linear Mode