Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

9Likes 9Likes

07-22-2011, 08:54 PM

|

|

CC Member

|

|

|

Join Date: May 2004

Location: centralia,

IL

Cobra Make, Engine: B&B cobra (sold), Hurricane HMS1002 (sold), Kirkham 289 FIA, (sold) RCR GT 40(sold) SPF GT40 2122(sold) Hurricane HMS2002, (sold) RCR SLC (sold) GTR on the way!

Posts: 1,288

|

|

Not Ranked

Not Ranked

I disagree with the 00 pump jet. Engines are different and have different fuel requirements. Mine bogs with the 00 and with the .55 but runs great with a .40. I have tested about every possible combination of jets, e-tubes and exhaust jets and that is what is making my engine happy.

__________________

High Maintenance Racing Team

Run & Gun 2003 - 2013

|

07-23-2011, 04:26 AM

|

|

Club Cobra Member

|

|

|

Join Date: Nov 1999

Location: Salem,,

NJ

Cobra Make, Engine: ERA 289 FIA #2100 Rio Red Wimbledon White Stripes 302 stroked to 331 Webers Richmond Road Race 5 speed

Posts: 782

|

|

Not Ranked

Not Ranked

I started with 50's, dropped to 35's and finaly with 00. You are correct that each engine is different with cam, heads and choke sizes.

__________________

Snakebit

|

07-23-2011, 12:33 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Copied (and edited) from Holley site but says it pretty well, regardless of carb type....Webers or Holley

The main or high-speed air bleeds (Air Correctors in case of Webers) affect the entire range of the main-metering system. The purpose of the main metering system and main air bleeds is to emulsify the fuel before entering the discharge nozzle to be discharged into the air stream in the venturi. The fuel/air mixture

becomes leaner as air bleed (Air Corrector) size is increased. Decreasing the size of the main air bleeds (Air Correctors) will decrease pressure across the main jet, which in turn will pull more fuel through the main system creating a richer fuel/air mixture. The main or high speed air bleeds also act as an anti-siphon or siphon breaker so fuel does not continue to discharge or dribble into the venturi after airflow is reduced or stopped. At high speeds the fuel/air

mixture must be on the rich side to prevent damage to the engine.

The idle system supplies fuel at idle and low speeds. The idle system requires a richer mixture than at cruise speed. Unless the idle mixture is

richer a slow and irregular combustion will occur known as a rough idle. Decreasing the idle air bleed size richens the idle mixture by increasing

the pressure drop in the system. Increasing idle air bleed size leans the idle mixture by reducing the pressure drop across the idle air bleeds.

The same conditions can be created by backing out the idle mixture screws, which will increase the pressure across the idle air bleeds, pushing

more fuel from the idle well creating a richer fuel/air ratio. The Idle mixture screw is the only adjustment recommended for controlling the idle

fuel/air mixture richness or leanness.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 07-23-2011 at 03:15 PM..

|

08-18-2011, 04:27 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

To update my previous L/R problem I did the following:

1. Undid both idle set screws and made the engine idle by hanging in the linkage and trottle wire (800RPM).

2. I then synchronized/ balanced the carbs by adjusting L/R and fore/aft linkagees.

3. Set the idle using idle set screws to 1200 rpm. By then the carbs were no longer fully synchronized (because of different kinds of faults in the linkage system), but they will be when on throttle.

It gave the smoothest running I have seen so far.....

On the 00 exhausts, there are different opinions. I haven't fully experimented to see what happens when they're opened up... I just refer to what I find in books etc.

|

05-01-2012, 03:17 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

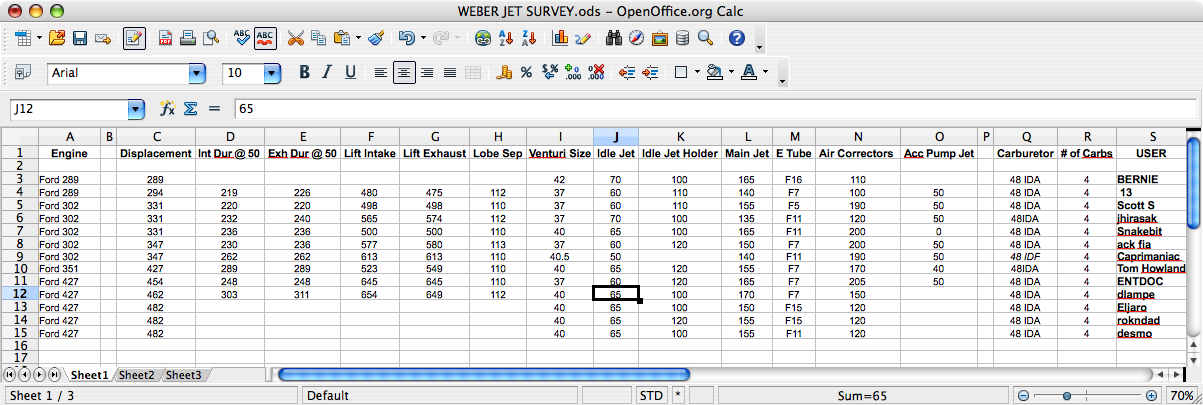

I'm Rebuilding the Jetting Database. If you have any changes or more info, please post them so I can update it. For those of you who have since joined the Weber ranks, please list your specs so we can build a library that is useful to the new enthusiasts who want to give it a go! If you have any other engines or know of any others, (I don't care what they are so long as you have the full specs)feel free to email me the details & I'll add to my list. Thanks, Hyde

__________________

ERA FIA 2088

Last edited by *13*; 05-05-2012 at 09:54 AM..

|

05-01-2012, 09:06 PM

|

|

Junior Member

|

|

|

Join Date: Dec 2000

Location: Corralitos,

CA

Cobra Make, Engine: 1980 Arntz 427W, Webers, TKO600, Jag IRS

Posts: 476

|

|

Not Ranked

Not Ranked

Thanks Hyde for doing this.

I'm running a 427W, Comp cam 35-425-8, @ .050 282/289,230/232, total lift .523/549, separation 110.

venturi 40, idle jet 65, idle jet holder 120, main jet 155, E tube F7, air corrector 170, acc pump jet 40, by pass 00, idle screws 1 1/4 turns.

Currently the idle is rich, transition is lean and mains are lean and there is a stumble at acceleration.

I use an an A/F meter and own about a pound of brass jets.

I've been working on these for a year now and have made some progress but I am not there yet!

A big discovery for me this last 2 weeks has been (thanks to jhirasak) the 25mm needle valve height. 3 of them were so far off I had to put them in a lathe and shorten them. I also installed sealed bearings (thanks to big deuce). I flowed them with a shop vac and made a tool to twist the shaft on one carb. I plugged a transition hole and redrilled it (thanks to big deuce). The bell crank is off center 3/16 in. so I'm going to weld it closed and redrill. I have a center bell crank that has the linkages coming from under the butterfly shafts. I would like to change that configuration to have the linkages above the shafts so it is easier to adjust. Does any one have that configuration? I would love to see your pictures.

__________________

Tom

|

05-01-2012, 11:52 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

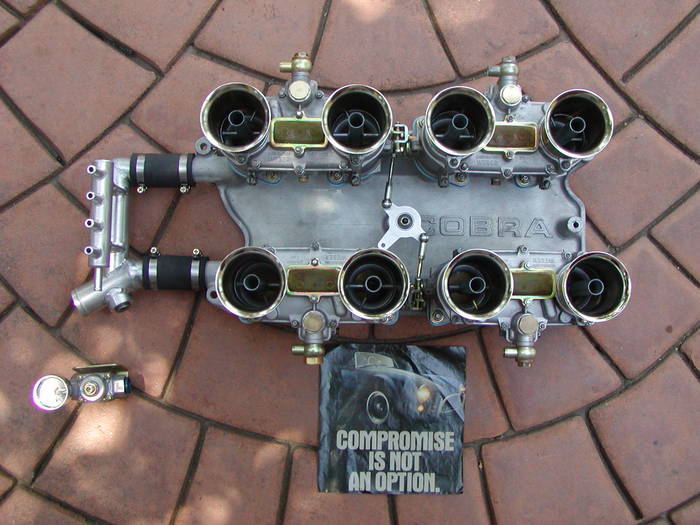

[IMG]  [/IMG]

Try to keep the pull arms as level as possible (there will be some arc, try to minimize it). The arms must be parallel, and the same length. In my case the pivot point for the bellcrank had to be moved rearward about 3/4"". I used a piece of 1/4" thick aluminum.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 05-02-2012 at 12:07 AM..

|

05-02-2012, 09:21 AM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Redondo Beach,

CA

Cobra Make, Engine: 331 SB, AFR heads

Posts: 75

|

|

Neutral

Neutral

Hyde,

Please update the information that I provided earlier to you. I am currently running a Windsor 331 roller block with a Comp roller hyd cam XE282HR-12 with the following specifications: Gross valve lift .565 In/.574 Ex; Duration @ .050 232 In/240 Ex; Lobe separation 112.0 degrees. Ignition setting: 18 deg initial, 38 degrees total @ 3000 RPM.

The 48 IDA specs are as follows: Venturi 37 mm; Idle jet 70; Idle jet holder 100; Main jet 135; E-Tube F11; Air Correction 120; Acc Pump bleed 50.

The engine runs without flat spots after it warms up and get around 15 mpg on the highway and 10 mpg around town.

|

05-02-2012, 12:49 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Will do guys, thanks! Should have it updated this eve. Hyde

__________________

ERA FIA 2088

|

05-02-2012, 04:35 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Updates have been made. Let me know if any of you want to make changes or add your info to the list. Thanks, Hyde

__________________

ERA FIA 2088

|

05-05-2012, 03:44 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

Great work, Hyde.

A useful reference list for all of us.

Personally I'd like some more data for the IDF setup.... I fell kind of lonely; I'm the only IDF-er on your list.

RS

|

05-05-2012, 04:06 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Caprimaniac

Great work, Hyde.

A useful reference list for all of us.

Personally I'd like some more data for the IDF setup.... I fell kind of lonely; I'm the only IDF-er on your list.

RS

|

Yes, good work Hyde.

Don't feel lonely Rune, I'm an IDF-er and a DCOE-er.

__________________

Gary

Gold Certified Holden Technician

|

05-05-2012, 04:45 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Maybe you can be the inspiration for those who want to be a little quirky

__________________

ERA FIA 2088

|

05-07-2012, 03:36 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by *13*

Maybe you can be the inspiration for those who want to be a little quirky  |

Hi Hyde,

My inspiration would be to have an IR manifold (one choke per cylinder) that has a rotating barrel or slide throttle to pair up opposing runners so then each cylinder can breath through 2 chokes at high rpm.

I could then have a 32mm choke for low speed and twin 32mm chokes for high speed per cylinder instead of my single 38mm per cylinder.

I'll do it one day.

__________________

Gary

Gold Certified Holden Technician

|

05-07-2012, 04:29 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

You'll need to post a build thread on that one so we can watch it all happen! Sounds like fun

__________________

ERA FIA 2088

|

04-13-2014, 12:53 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Redondo Beach,

CA

Cobra Make, Engine: 331 SB, AFR heads

Posts: 75

|

|

Not Ranked

Not Ranked

PM Folder Full

PM Folder Full

Hyde,

Your PM folder is full and will not allow me to respond to you by PM. If you have a current data base containing the various 48 IDA jetting combinations, please send it to my at my email address as follows: jhirasak@gmail.com

I am sure that if you post the latest jetting database to the Weber Jetting Survey thread, you will have some additional appreciative members.

Cheers,

John |

04-13-2014, 01:17 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by jhirasak

Hyde,

Your PM folder is full and will not allow me to respond to you by PM. If you have a current data base containing the various 48 IDA jetting combinations, please send it to my at my email address as follows: jhirasak@gmail.com

I am sure that if you post the latest jetting database to the Weber Jetting Survey thread, you will have some additional appreciative members.

Cheers,

John |

Need more storage!!!! I deleted a few. I'll send you the info, thanks.

__________________

ERA FIA 2088

|

04-13-2014, 06:22 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Redondo Beach,

CA

Cobra Make, Engine: 331 SB, AFR heads

Posts: 75

|

|

Not Ranked

Not Ranked

Hyde,

Thanks for sending your latest jetting spreadsheet to me. Just as a point of interest, I would like to mention the jetting and other changes that I had to make to a set of brand new 48 IDA Webers (out of the box from Redline) to get them to run smoothly on my car. They are as follows:

1. Adjust each float needle height to 25 mm by sanding the needle seat gasket (found a difference of up to 1 mm between the four carbs)

2. Adjust each float height setting after normalizing needle seat height

3. Adjust each carb air flow with butterflys closed so they indicate within 1 unit of each other reading on the air flow syncro meter (the general recommendation is to twist the throttle shaft to get the two throats to read the same value. I chose to drill small holes in the butterflys to get the same reading on all of the carbs)

4. Decrease Idle Jet holder from 120 to 100 to cure off idle transition hesitation

5. Adjust idle mixture screws to approximately 1 1/8 turns from closed (different taper on idle mixture screw than earlier Webers? Italian Webers might prefer 3/4 turns vs Spanish Webers like mine which might prefer 1 1/4 turns)

6. Change Emulsion Tube from F7 to F11 to correct for main jet transition richness (found problem by use of wideband O2 meter)

7. Change throttle linkage from as-provided single cross link to a bell crank arrangement to correct for left bank to right bank throttle position error (with single cross link arrangement, if both bank flow the same amount at idle, they would flow significantly different at 1800 to 2000 rpms, linkage geometry problem)

8. Change accelerator pump exhaust valve from 00 (blank) to 50 to correct for fuel dripping into the cylinders after hot shutdown (problem made worse by recent addition of alcohol in pump gas)

For anyone planning to install Webers on their car, I would highly recommend that they perform the first three steps listed above [u]before[u] they ever install them on the car for the first time.

John

|

04-13-2014, 07:05 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

John, just a note. My bell crank is not centered to the carbs. Changing to the bell crank has made a ton of difference. It'll never be perfect, though. Not noticeable when driving. If one has a choice of manifolds, this is a good question to ask. I know some have a centered mounting point.

__________________

ERA FIA 2088

|

04-13-2014, 10:56 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Redondo Beach,

CA

Cobra Make, Engine: 331 SB, AFR heads

Posts: 75

|

|

Not Ranked

Not Ranked

*13*,

When I changed my linkage arrangement from a single cross bar to a bell crank arrangement, I had to fabricate a mount that allowed me to place the bell crank povot in the center between both banks of carbs. This mount is attached to the manifold flange attachment bolts on both sides of the engine with longer bolts to compensate for the additional thickness of the mount. Perhaps you could fabricate a similar mounting plate and place your bell crank where you desire.

The use of a bell crank with carbs that are mounted with the fuel bowl inlets pointed in the opposite directions significantly improved the ease of tuning and drivability of my car. I would highly recommend this linkage arrangement for anyone who still has a single cross link setup and is having a problem tuning their 48 IDA Weber setup.

If anyone has a 48 IDA manifold setup that has all of the fuel bowl inlets pointing in the same direction, the single cross bar linkage is more appropriate for use.

John

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:24 PM.

Links monetized by VigLink

|