Following is a little analysis and research I did to better understand what's going on with webers, given all the stories vs Holleys. I should preface this by saying I am not a carburetor design engineer, so just looking at some basic things.

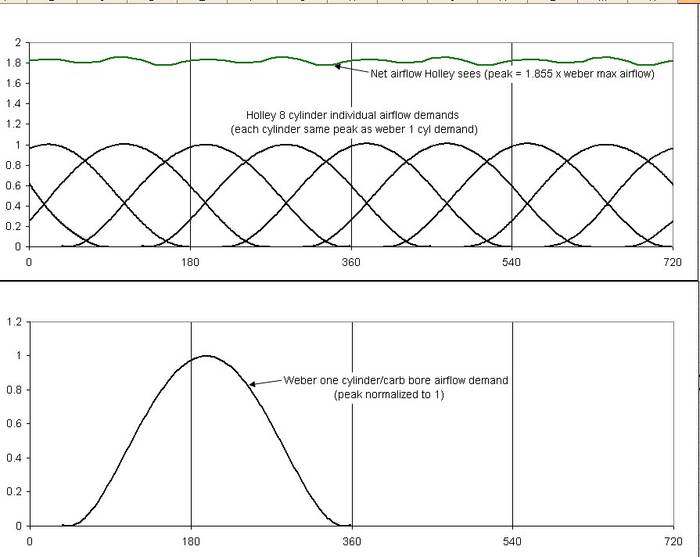

You often hear the statement thrown around that one cylinder of a V8 sees all four barrels of a Holley (open plenum config) which results in many people being misled. This graph clarifies what is going on (airflow demand approximated by typical valve lift time history):

The net airflow demand the Holley sees is surprisingly uniform and about 1.855 times the magnitude that a single weber barrel in an IR system would see on the same engine.

Now, given that a limiting factor of a carburetor is supposedly when the airflow through the choke reaches sonic velocity (I believe they may go above that, but performance is impacted), I will relate the airflow of the two systems at the choke point. Comparing the summation of the four choke areas of a typical Holley against one choke bore of a typical weber used on a big block, the 58mm: The Holley 780 has 1 3/8" and 1 7/16" choke diameters, which gives a total choke area of 6.216 in^2. A 58mm weber typical 52mm choke has an area of 3.292in^2. Now, since the Holley sees a greater airflow demand, to compare the two we can ratio down the Holley area by the airflow ratio, so 6.216/1.855 = 3.351 in^2. 3.292 is very close to 3.351, so this means that all else equal, a 780cfm Holley plenum setup would have about the same velocity through the choke as a 52mm weber choke in an IR setup on the same engine.

Kind of surprising. But Holley guys let's not get too excited yet. First of all, with the fairly uniform airflow the Holley sees, once you start seeing an airflow limit through the choke, there should be alot more abrupt manifestation of that "ceiling". With the weber carb, the peaky shape of the airflow demand curve intuitively means that as you hit any limiting velocity, the curve will tend to flatten out at the crest, but if you increase engine speed (flow) there will still be a net increase in area below the curve (increase in power), as it will get fatter at each end.

Another important aspect which many people miss is that a plenum of a Holley setup will always have an inherent energy/total pressure loss from the flow separation and recirculation (friction) that the plenum creates. For this reason, a friend on an F1 team has said they would never employ a plenum in the runner system of an optimized induction system (we're not talking about an air collection plenum aft of the scoop, as that is a different animal). Another disadvantage of a typical Holley plenum setup is that the runners are often not the same lengths, volume, etc, so the setup is not as finely tuned as a weber IR can be. The suction from adjacent cylinders also creates some level of vacuum in the plenum which is counterproductive to filling for any given cylinder (like the opposite of turbocharging). The net result of all these additional factors is that the 52mm choke weber example I referenced above is probably more equivalent to a larger Holley than the 780 I equated it to by just areas...how much larger would require a much more indepth evaluation, but who knows without testing - maybe similar to a 900-1000cfm Holley? I've heard references that supposedly peak power from a Dominator equipped big block would be in the ballpark of a good (ie; large choke) 58mm weber setup, so things make sense. Don't forget, however, that the weber IR setup still has the legendary advantage of greater lower/mid rpm power and resultant acceleration.

Anyway, additional constructive input welcome.

ps: It's interesting to note that the ratio of the choke area to the bore area of a 58mm weber with 52mm choke is exactly the same as an 850 Holley (80%).