Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

01-10-2009, 12:29 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

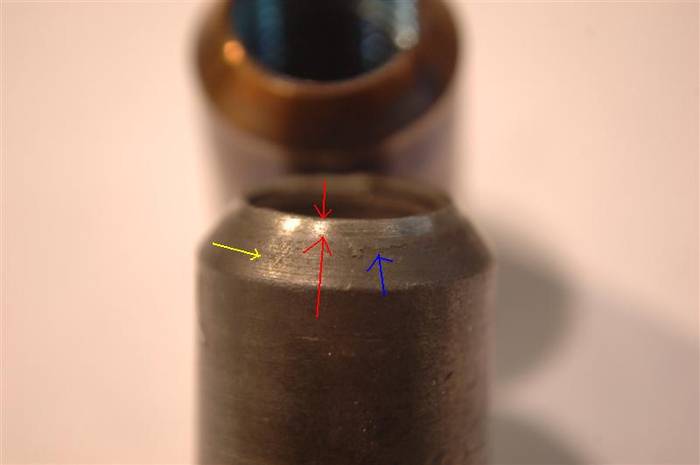

The yellow arrow shows the machining marks from the lathe that was used to make the taper.

|

01-10-2009, 12:32 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

The blue arrow points to junk from the black oxide process.

|

01-10-2009, 12:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

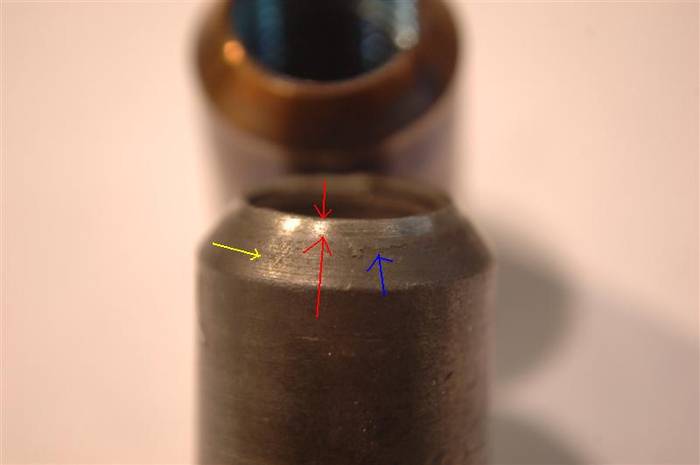

Now, this is a pin from CNGreen. It is most interesting. I doubt he even saw this.

This is a Trigo pin. The taper has actually started to crack. Again, notice the thin, shiny ring where the contact angle of the pin did not line up to the countersink on the hub adapter. Thankfully, he sent me his hub adapter as well.

This should put to rest the nonsense of outside corners not being stress raisers--this picture states other wise. ANY sharp edge is a potential to cause you grief.

The tape around the pin marks it as coming from CNGreen. (Had to keep all this stuff straight).

The plot thickens...

Last edited by David Kirkham; 01-10-2009 at 12:44 PM..

|

01-10-2009, 12:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

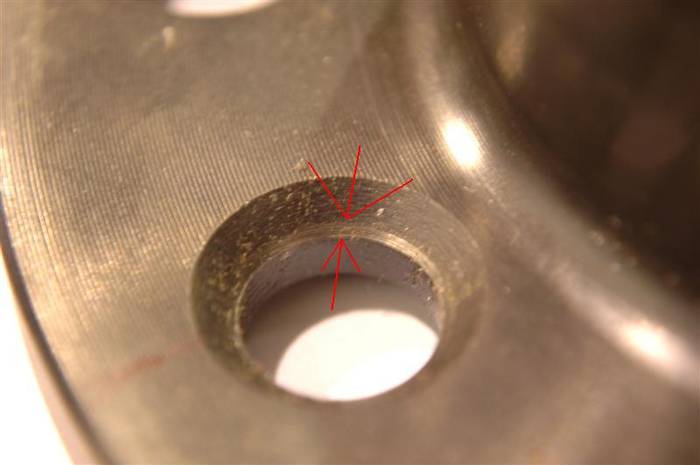

Here is the hub from CNGreen. This is a Trigo hub adapter.

Again, notice the shiny ring where the pin contacted the hub adapter. Notice it is extremely small. This is not a good situation.

|

01-10-2009, 01:00 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is an exaggerated view of what is going on.

This picture is of a Trigo pin. The pin is lathed to a 76 degree taper and the hub adapter is represented by the red lines.

|

01-10-2009, 01:01 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Cobra Make, Engine: SPF#0760

Posts: 3,409

|

|

Not Ranked

Not Ranked

Interesting, but I wonder how this fit-up differs from the hundreds of millions of regular passenger cars on the road today with regular lugs nut holding their wheels on? Still, it doesn't reflect well on the quality control practices in place of these preminm wheel manufacturers does it.

__________________

Wiring Diagrams: SPF MKII, MKIII, GT40, CSX7000, CSX8000, Corvette Grand Sport, and Shelby Sebring, Bondurant & Cinema Tribute Cars.

Owner’s Manuals: SPF MKII, CSX7000, CSX8000, Sebring, Bondurant, Cinema Tribute Cars $ GT40’s..

Large, easy to read and trace schematics with part numbers, wire colors, wire gauge, fuses, and electrical upgrade information. Trouble-shooting and replacement part numbers for those roadside repair adventures.

SPFWiringDiagrams@Comcast.net

|

01-10-2009, 01:09 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Blas

Interesting, but I wonder how this fit-up differs from the hundreds of millions of regular passenger cars on the road today with regular lugs nut holding their wheels on? Still, it doesn't reflect well on the quality control practices in place of these preminm wheel manufacturers does it.

|

I am quite sure regular passenger cars have very carefully controlled tapers that match between the lugs and wheels. Their quality control is really quite good.

As I explain more of what is going on, I think you will agree with what I think is going on.

David

|

01-10-2009, 01:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

In this picture, I flipped the pin over so it would be easier to understand what is going on.

The pink and green lines represent the wheel pushing on the pin during acceleration or braking.

The red line represents the 90 degree taper of the hub adapter. (I have exaggerated the angle to make it easier to see what is going on.)

The yellow line follows the 76 degree taper of the pin.

The blue lines represent your underwear.

|

01-10-2009, 02:07 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

So...

What exactly is going on?

Let's do a thought experiment.

Would you rather Jamo stepped on your foot with his shoes?

or

Would your rather have a tiny 100 pound woman step on your foot with a stiletto heel?

This, is called psi, or pounds/square inch.

Mild steel (1018) has a yield strength of around 50,000 psi. No matter how hard you jump on it, you probably won't do anything to it.

Now, take a simple nail in your hand and scratch the steel. Can you do it? Of course you can. If you push hard enough, you can probably even pull up a burr on the steel. Now, you can only pull up a burr if you YIELD the steel or surpass 50,000 psi. That means you somehow put OVER 50,000 pounds/square inch on the steel. So, you lean on the steel (maybe 100-150 pounds) and you drag a SMALL nail across the surface...WALLLA, you get a scratch.

Now lets talk about your nuts (pins).

People on this thread have been talking about pins loosening up, using Locktite, galling, and all sorts of other nasty things.

Why would, could the pin loosen up? I mean your torqued it to 80 foot pounds, right?

Well, if you have a small area of material (think the small shiny ring in the above pictures) and you put a lot of force on it (think 60-80 foot pounds of torque multiplied by the mechanical advantage you get due to the incline of the threads on your nuts) then you have put a lot of force (pounds) on a very small amount of area (square inches). (Kinda like that woman who stomped on your foot with high heels or that nail you scratched the mild steel plate with.)

Now it gets worse. The very, very small end of taper on your nuts is rather sharp. There is very little material there...or there is a small amount of square inches of material there. As the square inches go down, the pounds required to yield that particular area goes down as well. Think it is way easier to bend a paper clip than it is to bend your shift lever. Why? There is more material in your shift lever to bend EVEN THOUGH the yield strengths of the shift handle and the paper clip are roughly the same.

Well, it gets even worse.

Take the pin and load the contact area further by bending the pin with your wheel as you accelerate or brake. The pin will smash even further into the small contact area until it...yields.

Yield means it moves. Now there are two types of yielding-- elastic and plastic. Elastic yeilding is what happens in a typical spring. You apply the force the spring deflects and then when you remove the force the spring moves back to its original position (or shape). Plastic yielding (or more correctly stated plastic deformation) occurs when you go beyond the elastic range and go to where you are permanently bending the material. A good example of this is when you play with a slinky. In the beginning, you play nicely with the slinky it will always return back to the original position. Then you get a little naughty and pull it too far you bend the coils. You ALL KNOW what I am talking about. What has happened is you have plastically deformed your slinky. In other words you bent it. Now back to the your nuts.

If the material under the nut (or heaven forbid, your nuts themselves) yields into the plastic region the preload that you had on your nuts is now gone. In other words, your nuts are now loose.

David

|

01-10-2009, 02:39 PM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: Cape Town, South Africa/Mainz, Germany,

Posts: 1,601

|

|

Not Ranked

Not Ranked

Sadly, that problem has been around for years with "wheels sticking" (due to non-concentric nuts)

I had new nuts done for my clients in Germany and South-Africa since years.

Gladly, we found someone to take on the problem in the US and solve it with the help of all here :-)

Ironically, Kirkham does not even use that setup!

Now we can start a new thread about the spinners...

Dom

__________________

If I don't respond anymore, that's because I can't log in

|

01-10-2009, 02:52 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Dominik

Sadly, that problem has been around for years with "wheels sticking" (due to non-concentric nuts)

I had new nuts done for my clients in Germany and South-Africa since years.

Gladly, we found someone to take on the problem in the US and solve it with the help of all here :-)

Ironically, Kirkham does not even use that setup!

Now we can start a new thread about the spinners...

Dom

|

Dom,

Another problem I did not address is the potential under such extremes for galled material to push itself under one side of the nut and "tip" it to one side or another. Thus making wheels very hard, if not impossible, to take off and put back on as the bolt hole circle will not be in the proper orientation.

Bending the pin straight is a very BAD idea. You will load an even smaller area of the pin on the side you bent it towards and have the pin fail even faster. If the pins don't line up then you need to step back, find the problem, and correct it.

I will address concentricity shortly. I suspect it is not too good.

David

|

| Thread Tools |

|

|

| Display Modes |

Hybrid Mode Hybrid Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:48 PM.

Links monetized by VigLink

|