With the clutch bolted up it was time to check the clutch clearance. This was something I hadn't really understood when I first assembled the clutch and gearbox. I took for granted that the guys from SPEC who sold me the clutch would have the clearance pre-set.

So what I've found since messing with these a gearboxes is that there is often insufficient clearance between the slave cylinder when fully compressed and the fingers of the clutch. When the clutch wears the fingers steadily move further away from the flywheel face. This brings them closer to the release bearing/slave cylinder. If the release bearing can't go back any further the result is the pressure plate being slightly disengaged and the clutch starting to slip.

We don't think about it with a conventional clutch fork as there is usually plenty of external adjustment and travel. The Hydraulic throw-out bearing has no adjustment so needs adequate clearance set before assembling the whole thing.

To check you need to put a straight edge across the bellhousing and measure the distance to the fingers. in this case it's 53.57mm

Next we check the throwout bearing. Remove the spring and fully compress the hydraulic throwout. Measure from the bearing face to the front of the gearbox (where it bolts to the bellhousing). In this case it's 54.34mm

Subtract the available space between bellhousing and clutch fingers from the space used between gearbox face and throwout 53.57mm - 54.34mm = -0.77mm. That means my setup is running with the pressure plate fingers compressed by 0.77mm before I've even pressed the clutch pedal.

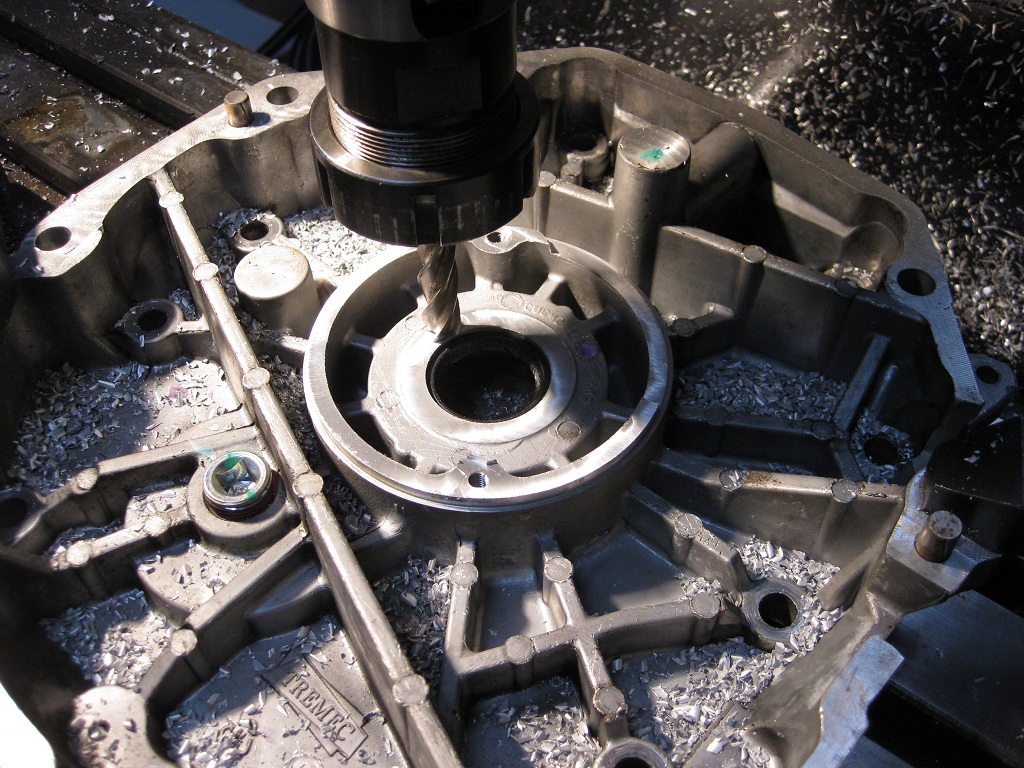

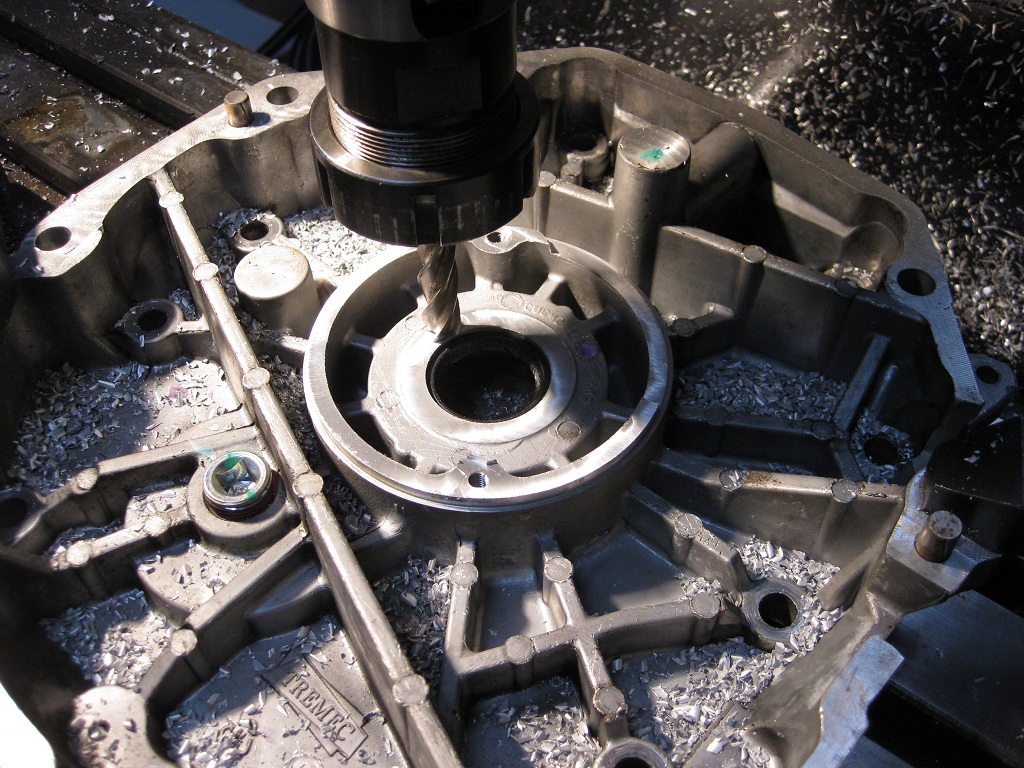

To rectify this I'll have to machine about 6mm off the mounting face where the slave cylinder meets the front of the gearbox. Fortunately I've made a fixture to make this an easy job on the milling machine.

If I'd put it back together as it was it wouldnt have been long before the clutch was slipping and stuffed.

Cheers

386Likes

386Likes

Hybrid Mode

Hybrid Mode