Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

March 2026

March 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

12-02-2007, 07:31 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

CR Rear suspension mods

CR Rear suspension mods

Hi All,

I thought I'd start a thread to doccument some of the rear suspension changes I'm making to my Classic Revival chassis.

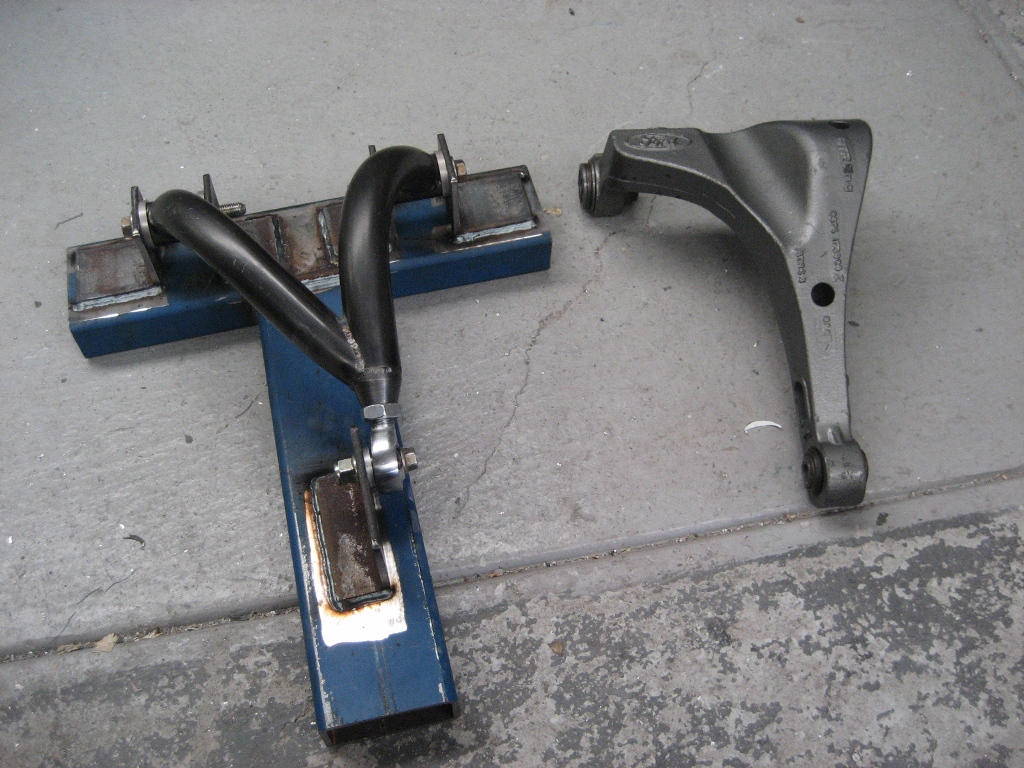

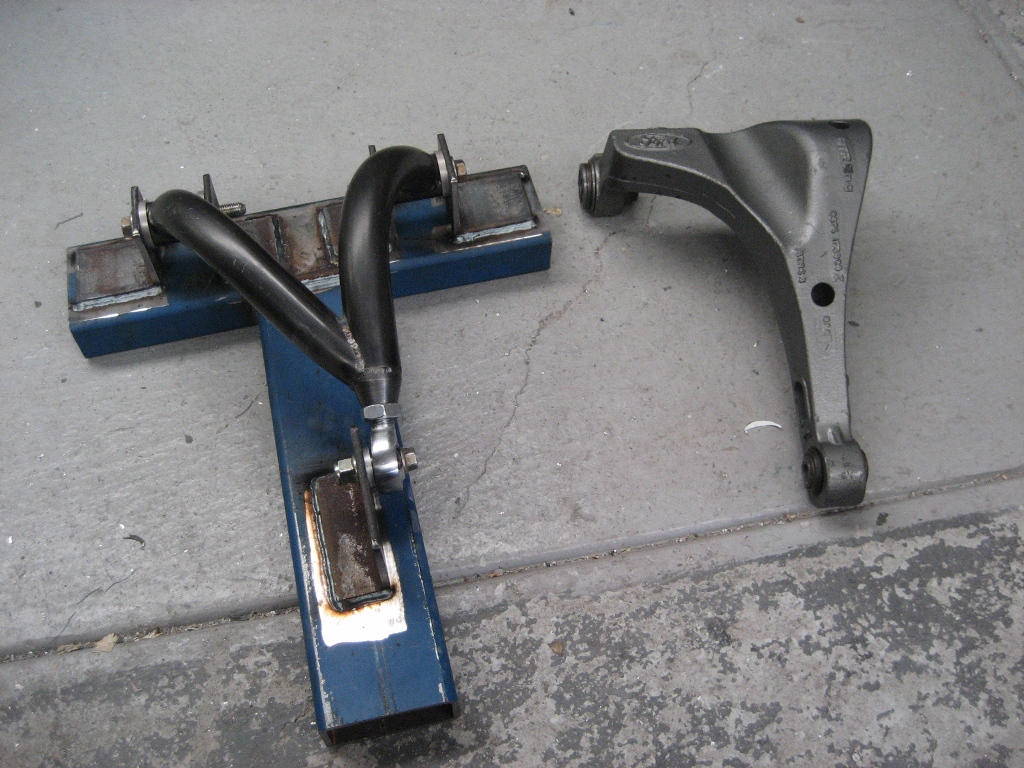

Here's a pic I snapped this morning of the trial fitting of a tubular lower control arm I've been working on. I built a Jig based on the original cast steel AU ford arm. The jig allows me to buld a lower arm in original length or 50mm shorter. Narrowing the rear end 50mm on each side will give me a bit more dish on the rear wheels and look heaps better.

The new arms are made from 4130 Chrome Molly tube and are significantly lighter than the original Ford arms. I'm hoping to cut 30KG out of the rear of the car with this setup. This is all unsprung weight too which should give the shocks and springs a better chance of controling the wheel.

I'm just working out the positioning of the new shock mounts at the moment so the arm will be in and out while I work out where everything should go.

Part of the new design is to remove the bump steer in the rear suspension that is a left over of the Ford design. I should be able to tune it out completely with this setup.

This arm design also alows me to adjust the camber from the bittom of the upright as well as the top. This will help with maintaining the right ammount of plunge on the rear axles.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 12-05-2007 at 07:13 PM..

|

-

Advertising

12-03-2007, 03:04 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Mildura,

vic

Cobra Make, Engine: FFR Coupe, 416ci of LS goodness

Posts: 2,349

|

|

Not Ranked

Not Ranked

Lookin good! One pair in black with red bushings please.

__________________

Powered by Cu

|

12-04-2007, 01:42 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: Melbourne,

VIC

Cobra Make, Engine: RMC, carb 347 TopLoader and Jag running gear ~ so old school I time it with an hour-glass :D

Posts: 1,293

|

|

Not Ranked

Not Ranked

Looking good Mike-

A bit more dish on the CRs wont go astray.

No doubt your plans will be popular with the other CR owners

Good thing you dont sleep with there only being a couple of months to ShelbyFest.

LoBelly |

12-05-2007, 04:49 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Another update with a few more pictures.

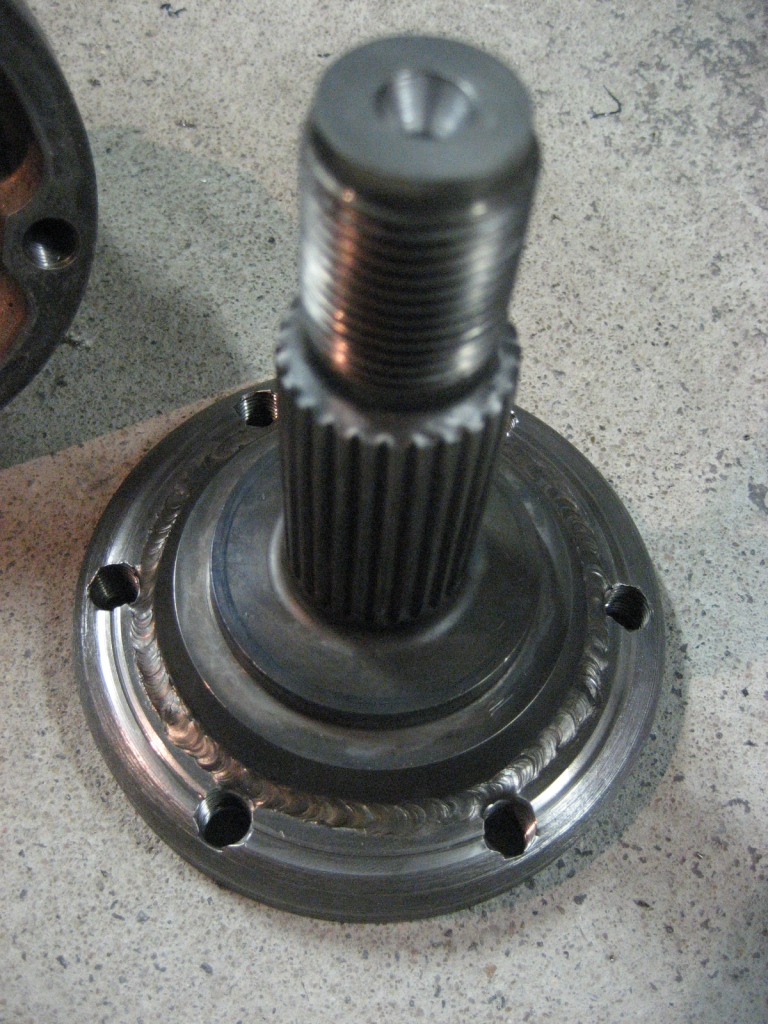

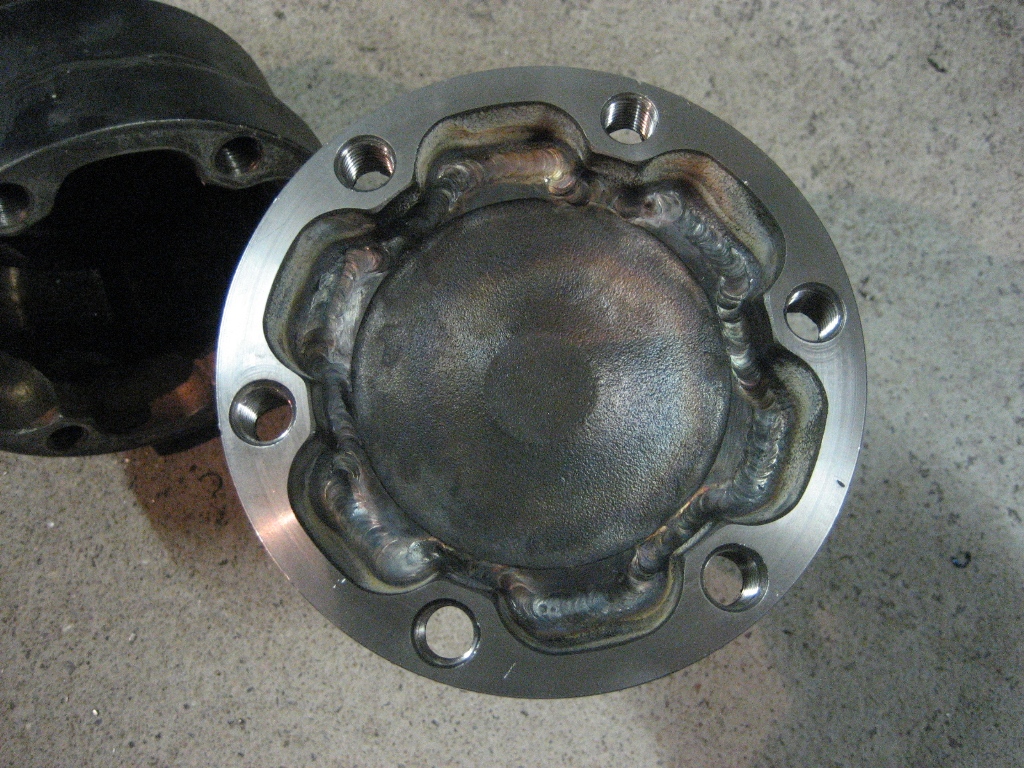

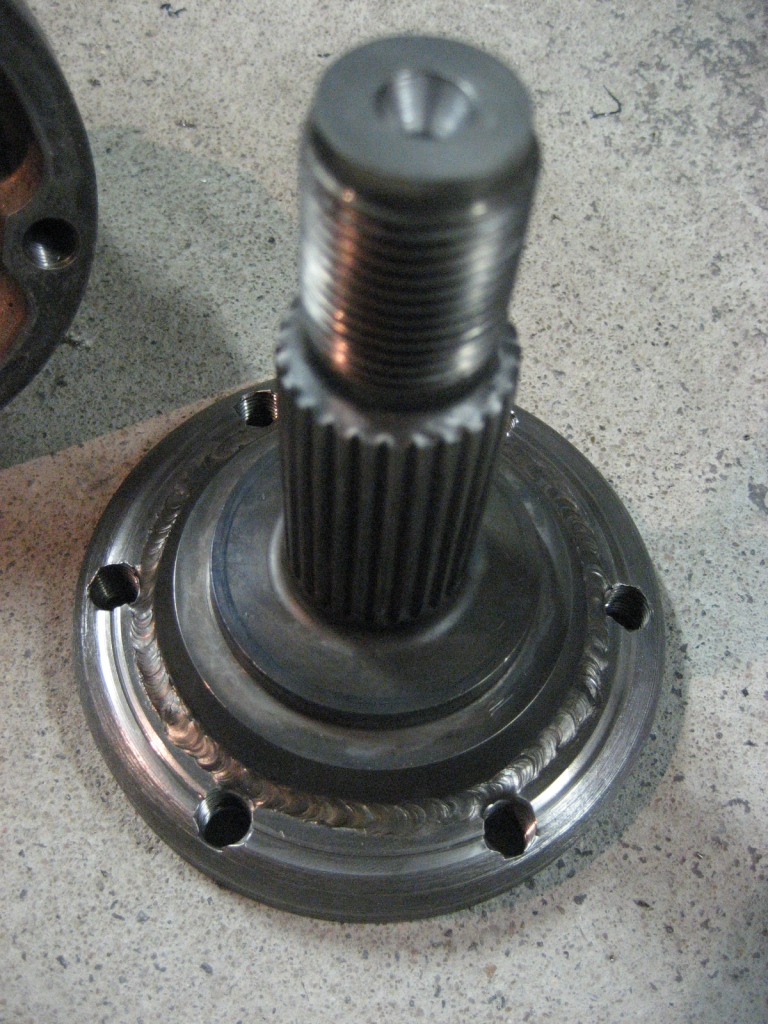

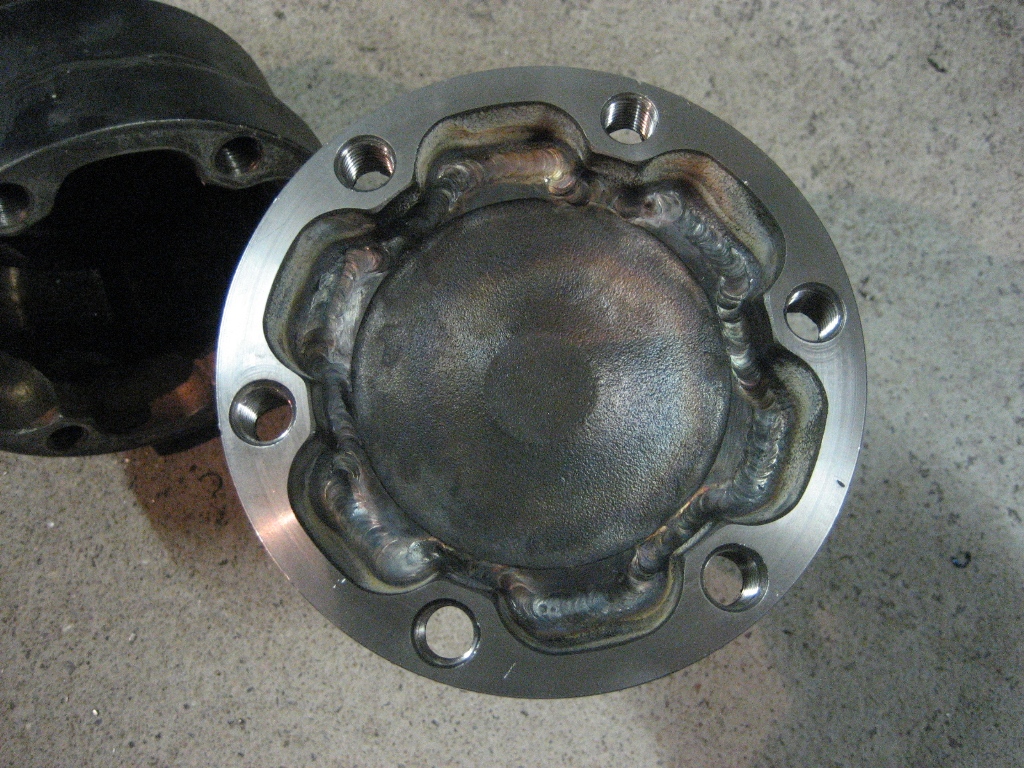

I tackled one of the more difficult jobs on the rear end modifications. The Axle flanges to adapt the Commodore axles to the Ford Hubs. The Commodore axles are narrower than the Ford and use a bolt up flange. I like these axles because you can just about remove the whole axle without unbolting all the rear suspension. I had made flanges previously when I did the Commodore diff conversion. The new ones had to be 50mm shorter for the narrowed rear end.

Here's the completed axle flange. It's made from an AU falcon axle mated to a Commodore diff flange. There was a lot of machining and setting up to get this together. The material the axle is made from is very hard and my tungsten carbide lathe tooling wouldn't touch it. I ended up having to rig up a tool post grinder to machine it down.

The 2 pieces are TIG welded together inside and out so should be strong enough. There are only drive loads going through the flange as all the suspension and braking loads are taken through the suspension arms.

Bolted to the end of the axle

With the Hub in place

The other thing I like about this setup now is that both CVs (inner and outer)are pretty close to in line with the suspension pivot points.

The next job is the new shock mounts and sway bar attachments.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 12-05-2007 at 04:52 PM..

|

12-05-2007, 04:54 PM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Location: Melbourne,

VIC

Cobra Make, Engine: Harrison, 6.0L Chev

Posts: 2,513

|

|

Not Ranked

Not Ranked

Mike, I think you might have been an automotive engineer in a past life! Brilliant work and nice pictures too. Good luck with the rest of the conversion.

Paul

|

01-14-2008, 01:31 AM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Darwin,

NT

Cobra Make, Engine: Classic Revival Kobra,LS7 427

Posts: 380

|

|

Not Ranked

Not Ranked

This is what philm will have to do now he has destroyed the ford set up

|

01-14-2008, 06:07 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I don't think this would have saved Phil's diff. He's making some serious mumbo and using drag tyres. That combination finds the weak link in any drivetrain.

The last update disapeared with the new server being installed.

Here's the pics again if any one is interested.

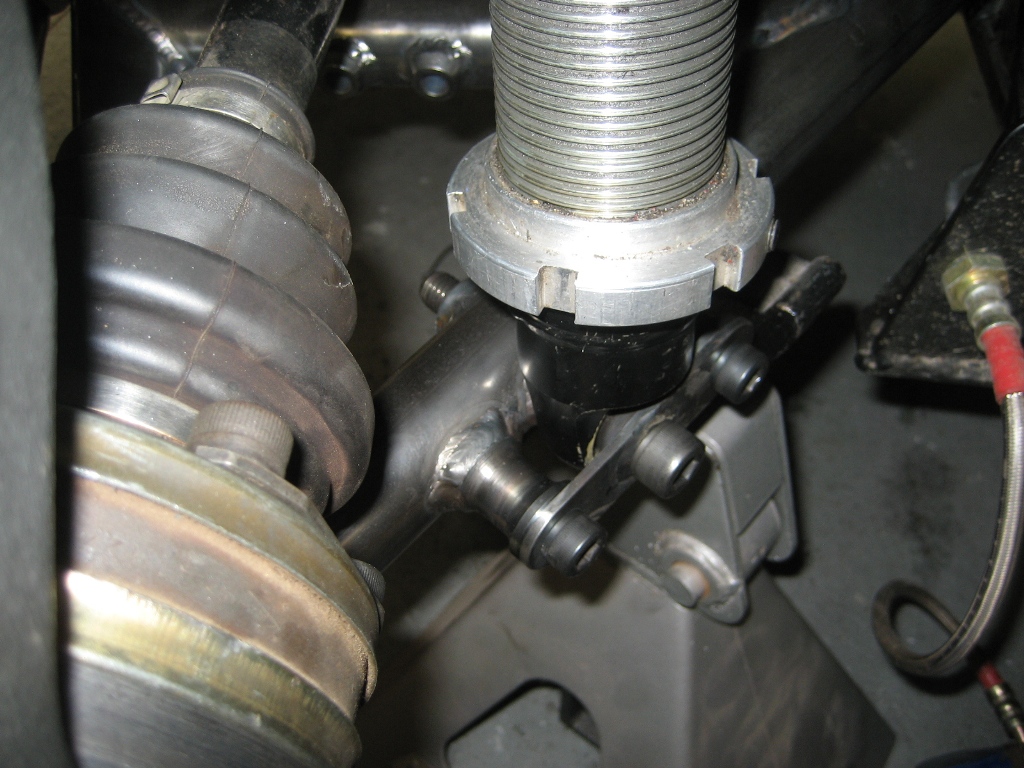

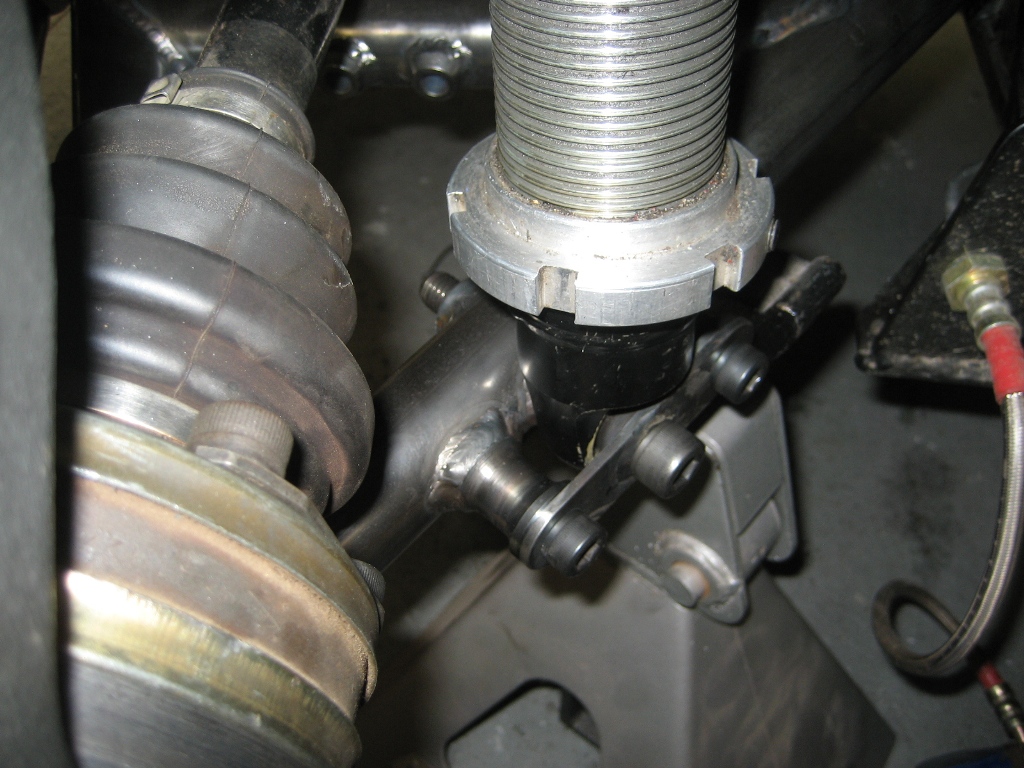

This is the new lower shock mount

The new track locater design that should eliminate the rear bump steer

This one shows the pick up points for the adjustable sway bar setup. The bars will be tubular with aluminum arms. They'll have a row of holes that will corespond with the holes in the arm and the sway bar can be adjusted by moving the links along to the appropriate holes.

I've just about finshed the upper arm. This took a bit of thinking to make something that will clear the upper chassis rails. I've also switched to a urethan bush design as I reckon the nylon bushes might be a little to harsh for the street. The urethan will also have a little give that will let it spring a little rather than pounding out to an oval shape from the changing loads.

Hope to have some pics of the upper arm in the next day or so.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-14-2008, 10:42 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Mike

Have you calculated the wheel rate........???

The motion ratio of the location of the shock doesn't look to good.....

The shock looks to be only mounted at about the half way point on the lower control arm........

could be the photo that gives it that look.....

Morris

__________________

Morris

|

01-14-2008, 04:21 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Hi Morris,

I think it's a bit of an optical illusion with the pictures. The shock mount is as far out as I can get it whilst still maintaining enough clearance to the back of the wheel rim. For wheel rate the ratio is actually better now than the original lower arm setup. I'll have to do a bit of math and work out the difference to the original Ford arms.

Here's a pic of the standard Ford rear end with it's cast steel arms. You can get an idea of the length of the arms and the position of the lower shock mount in relation to the wheel hub. My new setup has the shock in about the same position but the Hub is 2" closer in now.

The lower arms are quite long. My current wheels have a 9.25" back space and 2.875" front space. The Classic Revival chassis doesn't allow for a traditional looking wheel as you can see from this pic.

The new rear wheels have a 7.25" back space and a 4.875" front space.

I hope to achieve 3 main things with these mods. * A huge reduction in unsprung weight. * Eliminating the rear bump steer * Less offset on the rear wheels.

A couple of bonuses are positioning the wheel offsets so the loads are more evenly distributed on the wheel bearing. A better sway bar setup. And the tubular arms look cool.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 01-14-2008 at 04:24 PM..

|

01-14-2008, 06:05 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Aussie Mike

Hi Morris,

And the tubular arms look cool.

Cheers |

I agree.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

01-15-2008, 09:25 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Mike

I believe you are on the right track........ and it looks great......

But ..... as you know .... bump steer is controlled by the rotation of the upright...... so locating the upper control arm..... and then having the ability to move it in a fore and aft rotational movement will give you the bump steer that you are looking for..... Matching the two different arc's is where you will have the minimum bump steer.....

Just some thoughts....

Morris

__________________

Morris

|

01-18-2008, 02:47 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I'm a bit limited in what I can do by the chassis and the location of the existing mounts. I didn't really want to make any drastic changes to the chassis. So I'm just trying to change things to what I reckon might perform better within the existing mountings.

Currently the big rotation of the upright is a result of the track locator rod (if that's what it's called) working in a different arc to the upper and lower unequal length arms. With this type of setup I think it would be pretty difficult to eliminate all of the bump steer.

With the new setup I'm tying the track locator to the lower arm rather than the chassis. I can still adjust the toe OK and I can tune a certain ammount of bump steer in or out depending on the height I place the pivot point on the upright and how it relates to the pivot where the upright attaches to the lower arm. I can also dial in a lot more negative camber than the stock setup if I need it.

I have to say I'm having fun with all of this and the thought process involved.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-18-2008, 05:15 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: The Hills,

NSW

Cobra Make, Engine: Absolute Pace

Posts: 1,354

|

|

Not Ranked

Not Ranked

I have serious offset envy Mike!

I wish all of the classic revival cars had a few of inches of dish!

Perhaps the new chassis on the way will address this.

Ben

|

01-18-2008, 08:21 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Phil N mentioned he'd been and seen Ians new chassis. Suposedly he's using fabricated suspension rather than donor stuff. Hopefully he'll get on the forum and give us a sneak peek and some info on it.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-18-2008, 08:47 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I've made a bit more progress this last couple of nights. I've really got to get cracking on it or I won't be ready for Shelby fest. I'm also working up in India for the next couple of weeks so time is short.

Here'a pic of the new lower arm in the jig sitting next to the original arm. The bushings used in the jig are all machined from aluminum and locate all the pieces so they don't move when welding. They arms do spring a little when they come out of the jig so I still have to tweek them a little in the hydraulic press afterwards. I made some fixtures to let me do that accurately.

You can also see in this pic how the shock mout position is about the same place as the original. I've tried to move it in closer to the center line so it doesn't put as much of a twisting force on the arm.

Here's the finished upper arm in it's jig sitting next to the original. This took a bit of thinking to make an arm that would clear the upper chassis rail without having to cut anything.

The upper arm turned out nice and looks pretty cool with it's swoopy curves.

Both Jigs are made from some heavy wall RHS and are designed to make standard length or shortened arms. You wouldn't want to drop one on your toe either as they weigh a ton.

The next thing to sort out is the supension bushes. I've given away the idea of using nylon as I reckon it would pound out into an oval shape over time. I setled on Urethane as it has a little give in it that should make it last.

My local auto parts shop (who I often frequent) kindly let me go over their range of urethane bushes with a vernier caliper looking for something suitable. I finally found some bushes that had about the right dimensions or ID and OD. I made a small fixture that let me clamp the bush in the lathe and then with some very sharp tooling and a fast spindle speed I was able to trim them down to exactly what I wanted. I also machined up some steel sleeves for them to run on and they should work a treat.

The bushes on the right are the original. The ones on the left have been trimmed.

Now I've got to build the arms for the passengers side and paint everything ready for assembly.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 02-03-2008 at 07:55 AM..

Reason: spelling

|

01-18-2008, 10:04 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

That's gonna be one nice ride when you're finished Mike.

By the way.... The trick for machining urethane is to put the bushes into the freezer for a few hours prior to turning.

Now....back to the shed to work on my simple jag based ars....ermmmm.....rear end.

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

01-19-2008, 12:48 AM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Darwin,

NT

Cobra Make, Engine: Classic Revival Kobra,LS7 427

Posts: 380

|

|

Not Ranked

Not Ranked

I have heard that Ian is using tube for the main chassis rails and VE Commodore rear end set up and VE brakes all round.

|

02-10-2008, 07:08 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Time for an update

Well I lost 3 weekends in the shed because I had to go work in India. Things are not looking good for being ready for Shelbyfest.

I made a bit of progress on the weekend. The drivers side is pretty much done bar a coat of paint and final assembly.

I fabricated an upper shock mount to suit the new arms. One thing I found with the shock mount on the standard Ford setup is that the upper arm used to hit the chassis before the shock bottoms out on its bump stop. Maybe it's the 15" AVO shocks I'm running but for the new setup I thought I'd fix it. The new curved upper arm clears the chassis rail all the way and the shock bottoms out on its bump stop with clearance to spare.

I've got to get working on the passengers side arms now. The new rear wheels should hopefully arrive this week too.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

02-10-2008, 07:43 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: Melbourne,

VIC

Cobra Make, Engine: RMC, carb 347 TopLoader and Jag running gear ~ so old school I time it with an hour-glass :D

Posts: 1,293

|

|

Not Ranked

Not Ranked

Good Stuff Mike

Fingers crossed for an in-time-for ShelbyFest finish.

LoBelly

|

02-10-2008, 02:16 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Paradise Point,

Qld

Cobra Make, Engine: Absolute Pace

Posts: 1,205

|

|

Not Ranked

Not Ranked

What bump steer

What bump steer

Mike,

It looks fantastic.

I hope you make the Shelbyfest.

Phil

__________________

Not all driveways reach the street!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:02 AM.

|

|

Linear Mode

Linear Mode