Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

390Likes 390Likes

06-25-2017, 08:46 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Location: Queanbeyan,

NSW

Cobra Make, Engine: AP 289 USRRC #98 The Ken Miles Tribute Car

Posts: 1,134

|

|

Not Ranked

Not Ranked

Attachment method

Attachment method

How are you thinking of attaching yours Glen?

__________________

289 FIA Cobras RULE!

|

06-26-2017, 06:20 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by BJ's Snake

How are you thinking of attaching yours Glen?

|

M4 button head socket screws with Nylocs.

What hole pattern are you using for the airflow?

I'll send a PM with more detail.

Cheers,

Glen

Last edited by xb-60; 06-26-2017 at 06:39 PM..

|

06-26-2017, 07:50 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Location: Queanbeyan,

NSW

Cobra Make, Engine: AP 289 USRRC #98 The Ken Miles Tribute Car

Posts: 1,134

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xb-60

M4 button head socket screws with Nylocs.

What hole pattern are you using for the airflow?

I'll send a PM with more detail.

Cheers,

Glen

|

Single row large holes.

Look forward to see your idea of fixing the panel, I was thinking of fibreglassing it in somehow.

Cheers

Brett

__________________

289 FIA Cobras RULE!

|

06-26-2017, 04:56 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xb-60

What's next? I need to fit the diff. and half shafts, then the fuel tank, and then I can start fitting the sheetmetal panels in the boot/trunk.

Cheers,

Glen

|

Glen,

Is your build using transverse leaf springs? If it is you will have to check to see if the lower control arms are binding on the rear hubs. On my build the pressure of the transverse leaf springs caused the hubs to bind on the lower control arms, preventing rotating the hubs to install the half-shafts. We had to use a jack on the lower control arm to relieve the pressure from the leaf springs so the hub would spin. While we were there, we installed the rear shocks, as once installed they kept the pressure off the hub and allowed us to remove the jack and that was one less thing in the way.

Good luck with the build, and wear long sleeves while installing those half-shafts, not a lot of working room in their and my forearms are scuffed up pretty well from not wearing long sleeves.

Jim

__________________

|

06-26-2017, 06:33 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 1795

Glen,

Is your build using transverse leaf springs? .....

....Good luck with the build, and wear long sleeves while installing those half-shafts, not a lot of working room in their and my forearms are scuffed up pretty well from not wearing long sleeves.

Jim |

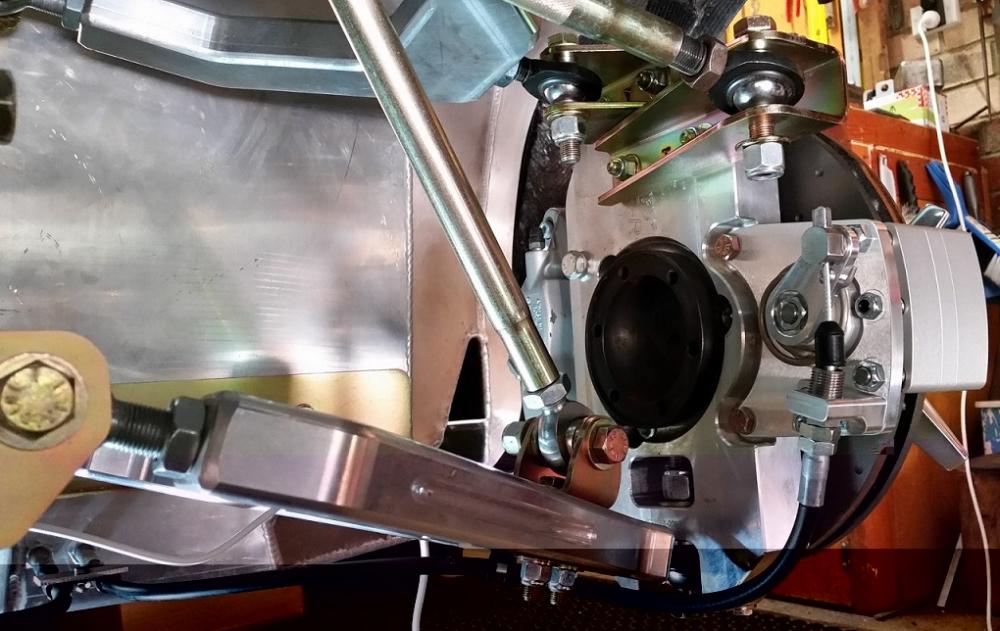

Hi Jim,

No, not transverse leaf. It's a bit more radical under the skin than (hopefully) it appears on the outside.

Here's a shot of the front suspension setup.

Rear is similar with pushrods as well. I think the diff. fit will be tight, but should be OK with the half-shafts.

Thanks for the thoughts...it's depths of winter here, so will have the long sleeves - and jumper - and overalls.

Cheers,

Glen

Last edited by xb-60; 06-26-2017 at 06:42 PM..

|

06-26-2017, 06:52 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Glen,

That should be a little easier than mine. Those leaf springs are rather stiff. Easier with coil overs. Good luck.

Jim

__________________

|

07-09-2017, 11:47 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Location: Queanbeyan,

NSW

Cobra Make, Engine: AP 289 USRRC #98 The Ken Miles Tribute Car

Posts: 1,134

|

|

Not Ranked

Not Ranked

Well done Glen.

__________________

289 FIA Cobras RULE!

|

07-10-2017, 12:31 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,129

|

|

Not Ranked

Not Ranked

Nice work Glen ... how did you make the holes, use a drill press or use something like a Greenlee punch?

|

07-10-2017, 01:22 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Hi Tim,

Thanks. No, didn't use a punch, just used 25mm and 12mm twist drills for my 2mm sheet

More to the story of course. I drilled a 25mm hole and a 12mm hole in a piece of 8mm thick mild steel bar and then I clamped the 8mm bar, the 2mm alum. alloy sheet and a short length of hardwood decking (around 70mm x 12mm section) down onto the table of my pedestal drill. The holes in the steel bar served as the guide for the drill bits and the hardwood supplied something solid enough so that the drill wouldn't grab as it slowly drilled through the alloy sheet. I had also marked up the hole positions and drilled 6mm pilot holes, but even still, as it's just an ordinary drill press, each hole position required checking and rechecking a number of times to get it right.

Turned out quite well.

Cheers,

Glen |

07-10-2017, 04:48 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Turned out very well Glen. You were smart to sandwich that alloy as I imagine that it would have caught in the bit and twisted if you were trying to drill that on it's own.

Moving along nicely.

Jim

__________________

|

07-15-2017, 09:23 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Photo bucket - what a disappointing outfit!

Looks like I have lost all of my pictures that I placed in Photobucket and linked to my build threads.

I will attempt to rebuild my two build logs.

Cheers

Glen

edit: replaced affected pictures in this thread

Last edited by xb-60; 07-16-2017 at 01:06 AM..

|

08-01-2017, 11:25 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Doing some prelim work prior to fitting the final drive....under the supervision of the site manager....

Pity that the whole right rear as well as the coil overs and mounting brackets have to be removed to be able to fit the diff. Darn cold out in the garage too!

Cheers,

Glen |

02-11-2018, 09:09 PM

|

|

CC Member

|

|

|

Join Date: Apr 2005

Location: Tucson,

AZ

Cobra Make, Engine:

Posts: 5,391

|

|

Not Ranked

Not Ranked

That's pretty cool! I switched the brake handle on my Hurricane to the same model you did. It had the short handle with the kit originally.

I had to make a bracket as well but mine protruded below the floor enough to have the cables below.

Larry

__________________

Alba gu bràth

|

02-20-2018, 01:10 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,129

|

|

Not Ranked

Not Ranked

Glen,

Pigeons or not, nice job. The overall design of the bracket looks good, I like the holes and beveling of the edges, nice touches. Will the rod scrape along the inside of the hole in the bracket, or will that be greased up enough to not be an issue? If you get really ambitious, a bushing of some type might be and idea, delrin would be a good choice. That being said, you have more than enough to keep you busy, so move along the the next task. Keep up the good work!

|

02-20-2018, 05:13 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Hi Tim,

Thanks for the comments.

Some technical stuff....the actuating force (from the handbrake handle) and the resultant force transmitted to the cables are almost parallel in the longitudinal direction (the slight difference being that the handbrake handle is mounted to the tunnel, which of course isn't parallel). This results in the transverse component of the force being very low and the load on the bracket being minimal. It all operates as smoothly and as positively as I thought it would.

Yes, enough to keep me busy, so maybe when everything else is ticked off, I can come back and add that Delrin bush

What’s your mileage count on that lovely ERA 289FIA of yours?

Cheers,

Glen

Last edited by xb-60; 02-20-2018 at 05:16 PM..

|

02-21-2018, 11:24 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,129

|

|

Not Ranked

Not Ranked

Hi Glen … the handbrake setup is very well engineered indeed, right along with the rest of the build, well done.

Was not able to get the Cobra out as much as I had hoped last year, so just under 8K miles to date on 2136. Will see what I can do about that this year. I bet you can hardly wait to get 2289 on the road ... that day just keeps getting closer and closer

- Tim |

02-27-2018, 11:18 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Handbrake installation progress has been a bit intermittent, but is now ticked off....

Here's the finished look for the handle:

...and here's the action end, with calipers installed and cables fitted and secured:

A bit of development work was required, but it turned out OK.

Cheers,

Glen |

02-28-2018, 05:13 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Looks very professional and well done Glen! Looks like it may actually work!

__________________

|

03-01-2018, 03:12 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

If it doesn't work.....I'm not telling anybody  |

03-04-2018, 03:17 AM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Adelaide,

SA

Cobra Make, Engine: ICCARS,6.0LT L98 TR6060

Posts: 78

|

|

Not Ranked

Not Ranked

Your build is coming along nicely Glen, good work on the hand brake.

It is very rewarding when you have an idea of what you want and then design and build it, and if it doesn't work out, you go to mark 2 design...

Cheers

Richard

|

| Thread Tools |

|

|

| Display Modes |

Rate This Thread |

Hybrid Mode Hybrid Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:58 PM.

Links monetized by VigLink

|